DAF CF65, CF75, CF85 Series . Manual - part 242

©

200324

4-3

Removal and installation

PE ENGINE LUBRICATION SYSTEM

CF65/75/85 series

2

7

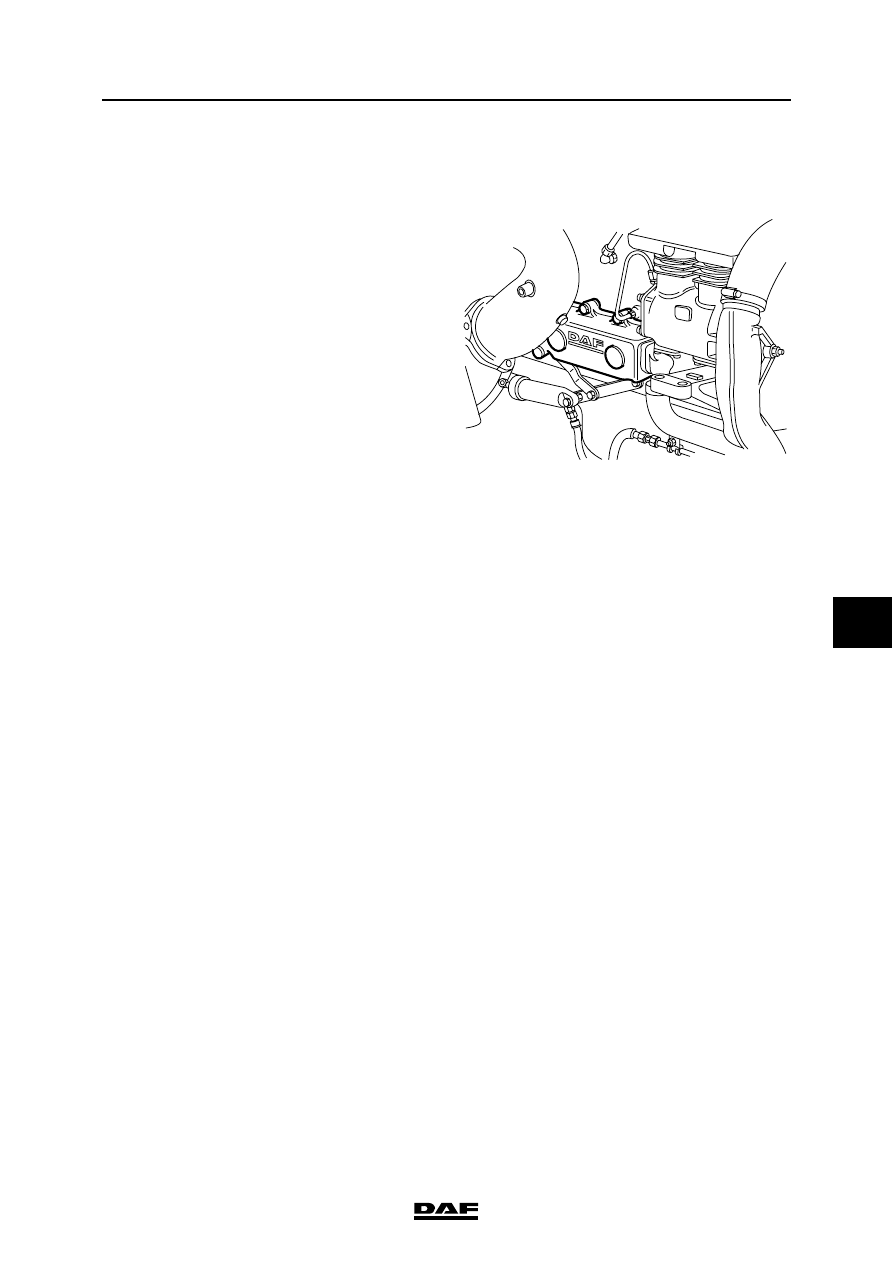

4.3 REMOVAL AND INSTALLATION, OIL COOLER

Removing the oil cooler

1.

Drain the coolant. See "PE engine cooling

system".

2.

Remove the heat shield from the exhaust

elbow.

3.

Remove the exhaust elbow and exhaust

brake operating cylinder.

4.

Remove the plug on the underside of the oil

cooler and drain the coolant.

5.

Remove the coolant hoses from the oil

cooler.

6.

Remove the oil cooler. Collect the escaping

lubricating oil.

7.

Remove any remnants of gasket.

Installing the oil cooler

1.

Thoroughly clean the contact surfaces

between the oil cooler and the cylinder block,

and replace the gaskets.

2.

Fit the oil cooler.

3.

Connect the coolant hoses to the oil cooler.

4.

Fit the exhaust elbow and exhaust brake

operating cylinder.

5.

Fit the heat shield of the exhaust bend.

6.

Fill the cooling system.

7.

Run the engine briefly, and check that the

lubricating oil cooler does not leak.

8.

Check the lubricating oil level.

9.

Check the coolant level.

W267003