DAF CF65, CF75, CF85 Series . Manual - part 144

©

200346

3-1

Inspection and adjustment

CAB TILTING MECHANISM

ΧΦ65/75/85 series

1

6

3. INSPECTION AND ADJUSTMENT

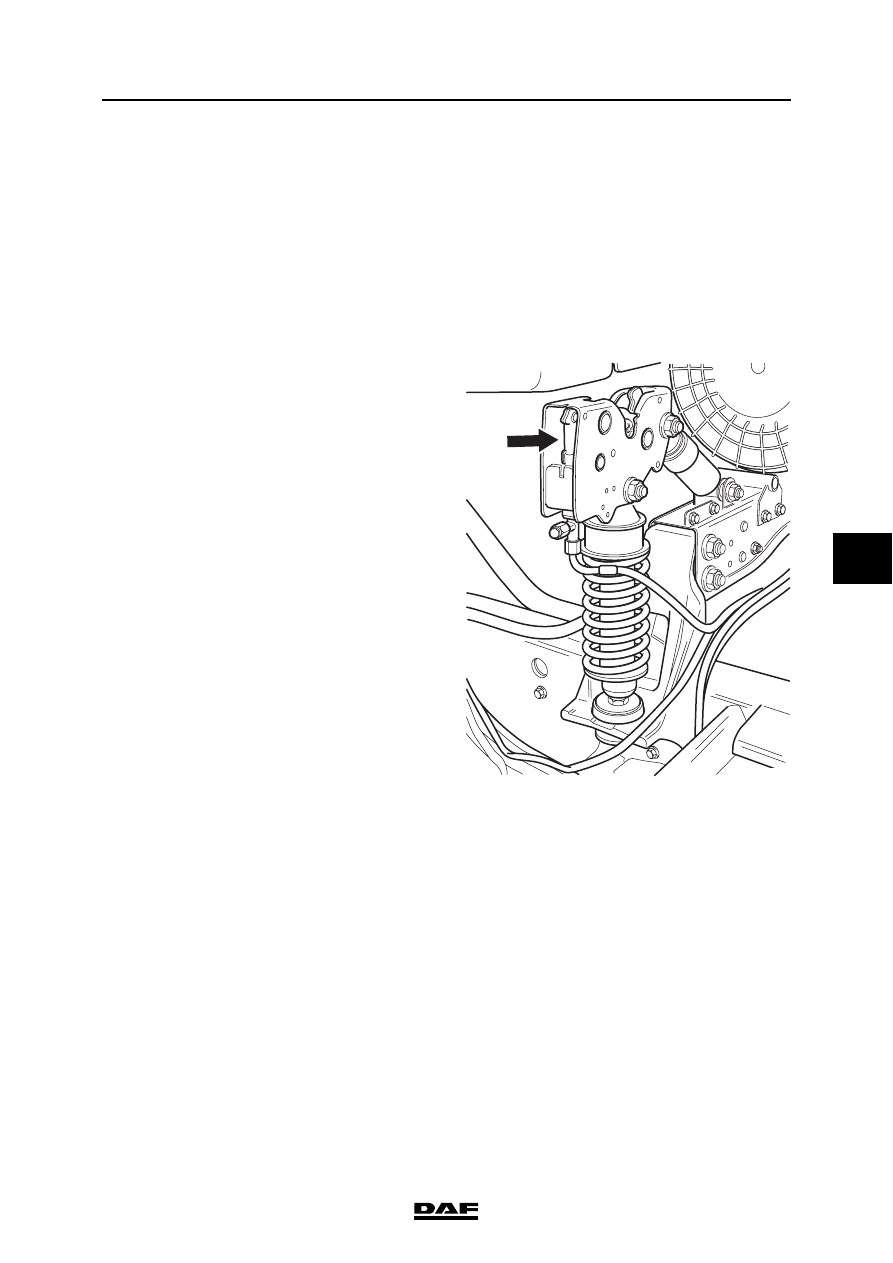

3.1 INSPECTING TILTING MECHANISM

1.

Check all pipes and connections for any

leakage.

2.

Check the cab tilting pump for leaks.

3.

Check the lifting cylinder and the cab locks

for leaks.

4.

Check that the pistons of the cab locks can

move in and out freely.

Note:

A defective cab tilting mechanism is often the

result of contaminated oil.

K1 01 659