Content .. 1124 1125 1126 1127 ..

DAF CF65, CF75, CF85 Series . Manual - part 1126

©

200518

3-13

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΧΦ65/65 (II) series

5

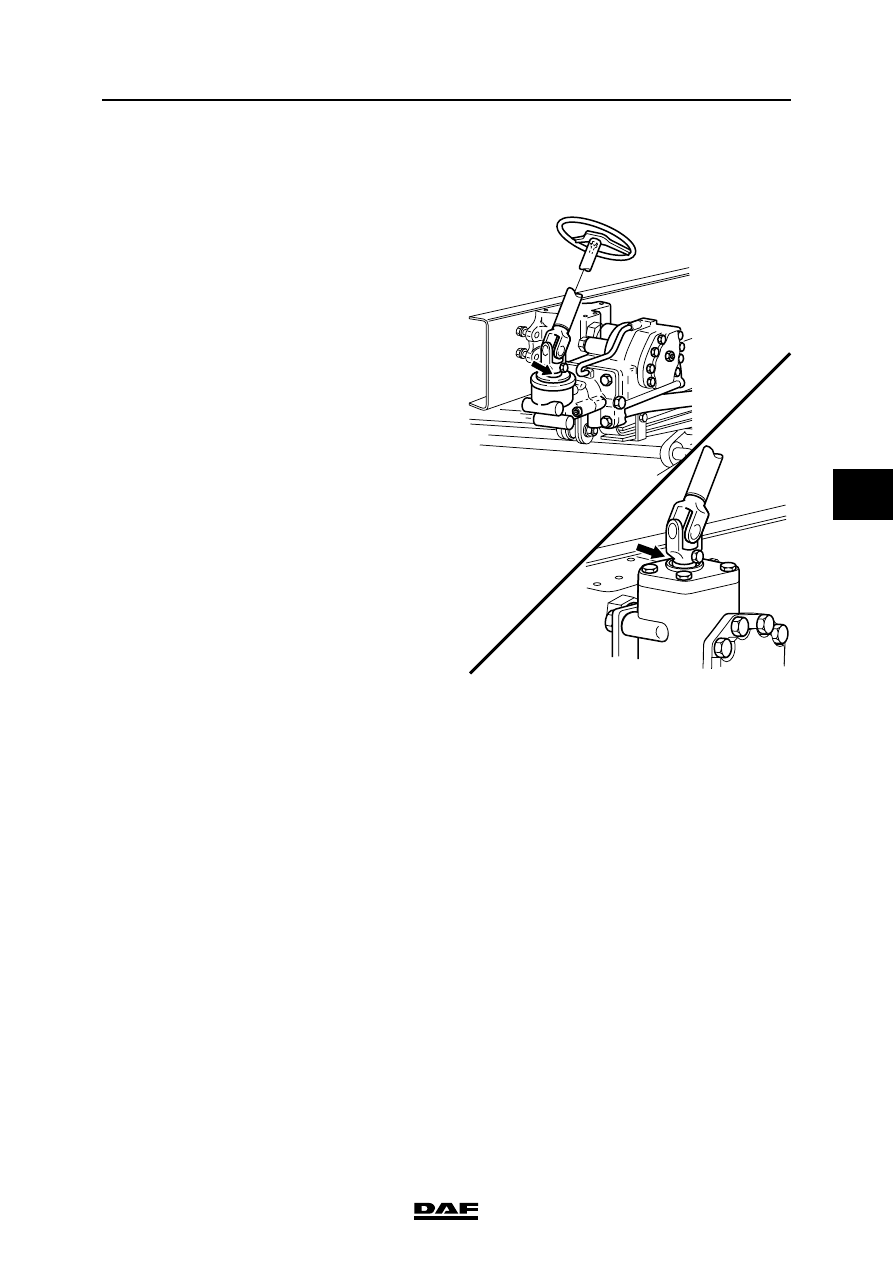

3.16 CHECKING FASTENING OF UNIVERSAL JOINT TO STEERING BOX INPUT

SHAFT

1.

Check the universal joint for perceptible play.

If perceptible play is detected, the affected

part must be replaced.

2.

Check whether there is any perceptible play

between the spline connection of the

universal joint and the steering box input

shaft. If perceptible play is detected, the

splines on the universal joint and those on

the input shaft must be checked for wear. If

wear is detected, the affected part must be

replaced.

3.

If there is noticeable play but the parts are

not worn, the attachment bolt and nut must

be replaced. Tighten the attachment bolt and

nut to the specified torque, see "Technical

data".

G000379-2

CF65

CF65 (II)