Content .. 1012 1013 1014 1015 ..

DAF CF65, CF75, CF85 Series . Manual - part 1014

©

200424

6-1

Tandem rear axle 1355T

DIAGNOSTICS

ΧΦ65/75/85 series

8

1

6. TANDEM REAR AXLE 1355T

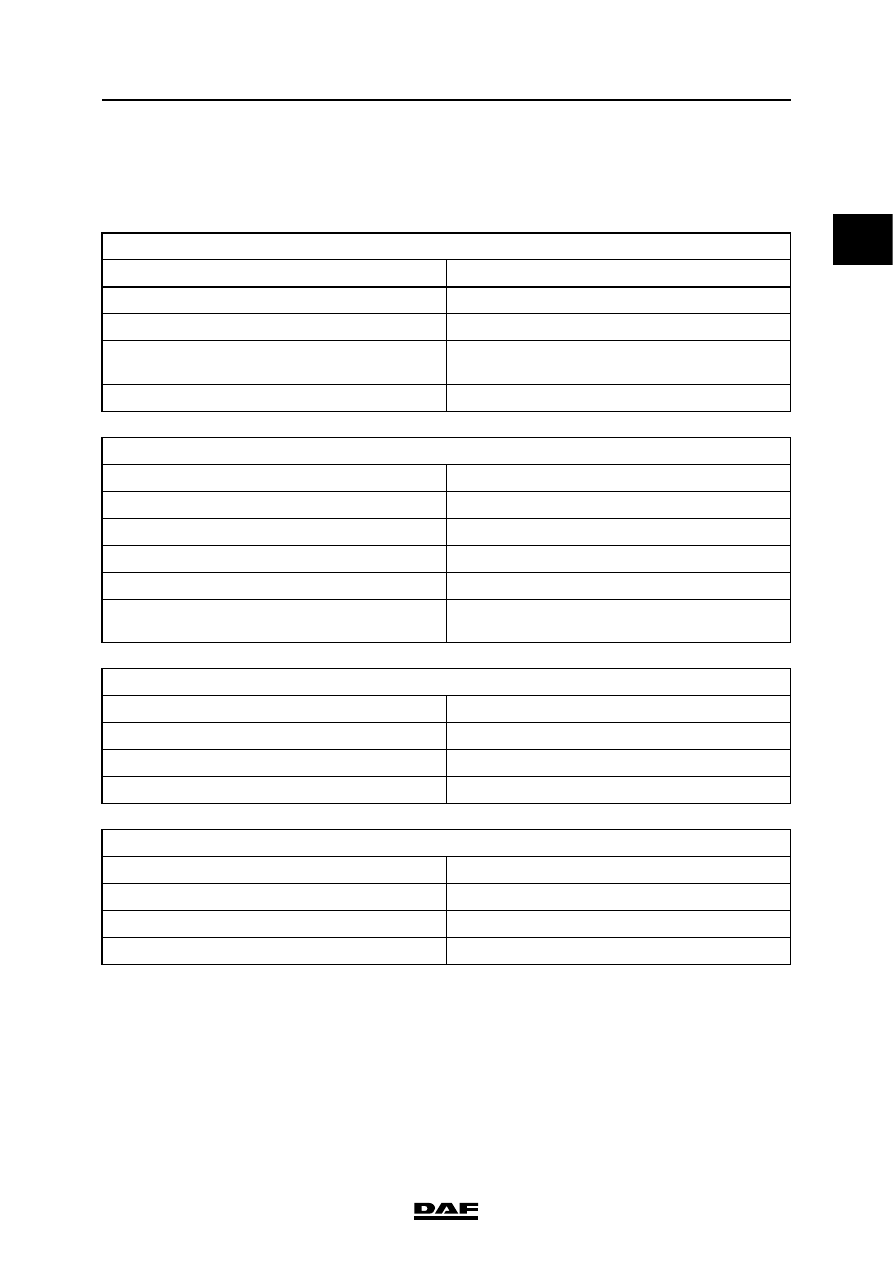

6.1 FAULT-FINDING TABLE

SYMPTOM: NOISES IN REAR AXLE AND DRIVE ASSEMBLY

Possible cause

Remedy

Oil level too low

Top up oil

Incorrect oil viscosity

Drain oil and top up

Loosened attachment bolts or broken differential

lock parts

Drain oil and check drained oil for presence of

pieces of metal

Pinion-bearing play

Adjust and/or replace

SYMPTOM: OIL LEAK

Possible cause

Remedy

Oil level too high

Drain oil

Incorrect oil viscosity

Drain oil and top up

Leaking oil seal

Replace oil seal

Bleeding system blocked

Clean or replace the bleeding system

Oil leakage between the differential gear housing

mating surfaces

Clean mating surfaces and apply new sealant

SYMPTOM: DIFFERENTIAL LOCK IS NOT FUNCTIONING

Possible cause

Remedy

No air pressure at engaging cylinder

Check compressed-air system

Defective pneumatic control

Check or replace pneumatic switch

Defective mechanical shift control

Check shift control

SYMPTOM: DIFFERENTIAL LOCK WARNING LAMP IS NOT FUNCTIONING

Possible cause

Remedy

Switch on cylinder fitted too high

Readjust switch

Switch on cylinder defective

Replace switch

Fault in electrical circuit

Check electrical circuit