Content .. 999 1000 1001 1002 ..

DAF CF65, CF75, CF85 Series . Manual - part 1001

©

200423

3-5

Removal and installation

STEERED TRAILING SWIVEL AXLE

ΧΦ65/75/85 series

7

7

3.2 REMOVAL AND INSTALLATION, TRACK ROD

Removing the track rod

1.

Remove the wheel speed sensor and the

connector bracket.

Note:

When the track rod has been removed, the

swivel axle can be at such an angle that the

wheel speed sensor is damaged, which can

damage the wheel speed sensor ring.

2.

Remove the attachment nuts. These nuts

should not be re-used.

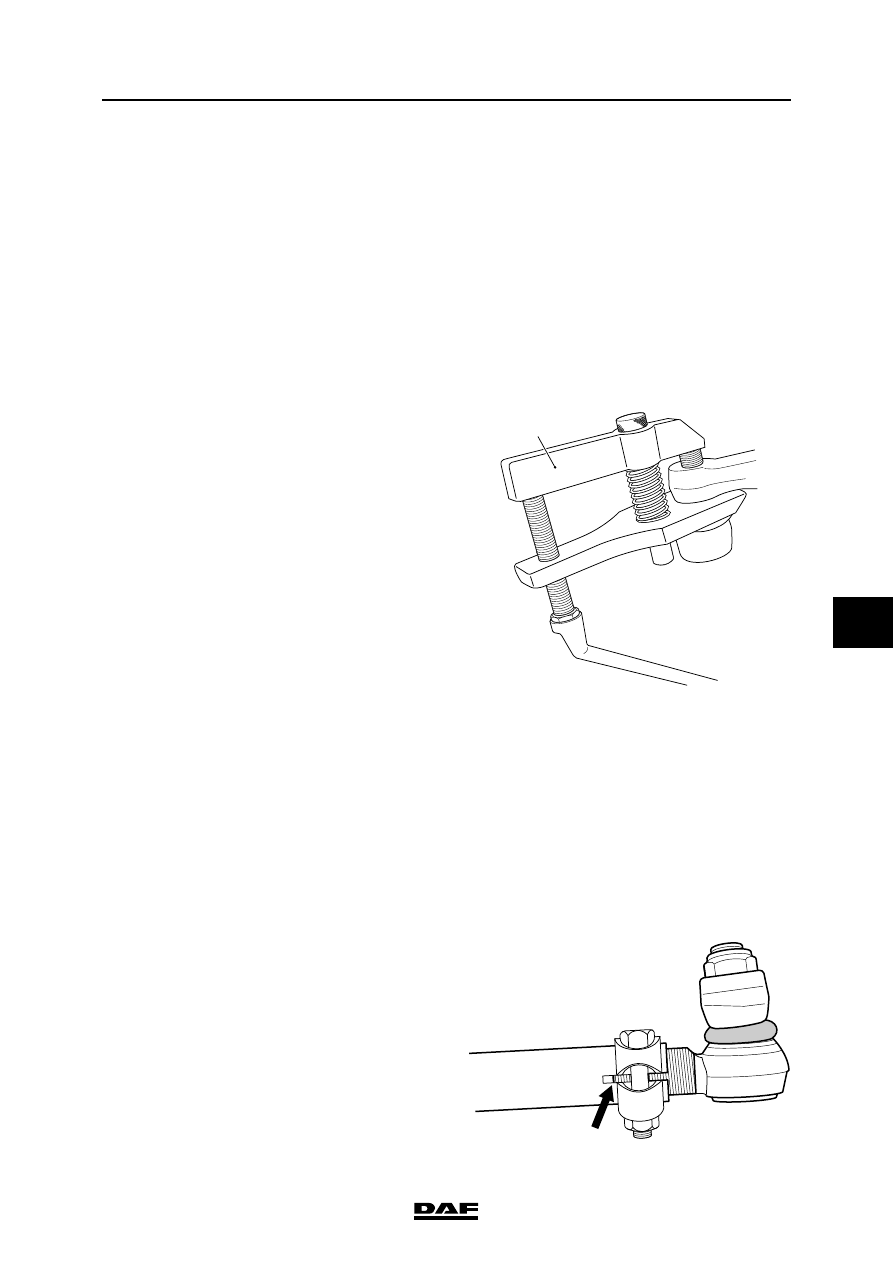

3.

Remove the ball ends from the track rod

arms using a ball end puller (A).

Installation of track rod

1.

If installing a new track rod, copy the settings

of the track rod to be replaced.

2.

Check the ball end thread for damage before

fitting a new self-locking nut. See 'Inspection

and adjustment'.

Fitting a new self-locking nut to a

ball end with a damaged thread may

lead to dangerous situations.

3.

Clean the tapered contact surfaces of both

the track rod balls and the track rod arms.

The tapered surfaces should be absolutely

free from dirt, grease and paint.

4.

Fit the track rod.

5.

Fit a new self-locking nut to the ball end.

Apply locking compound to the nut. See

'Technical data'.

6.

Tighten the new self-locking nuts to the

specified torque. See 'Technical data'.

7.

Check the axle toe and adjust, if necessary.

See 'Inspection and adjustment'.

8.

Check whether the threaded ends of the ball

joints are fully engaged by the clamping

pieces.

9.

Check whether the clamping piece bolts are

tightened to the specified tightening torque.

See 'Technical data'.

10. Fit the wheel speed sensor and the

connector bracket.

S7 00 555

A

}

S7 00 539