DAF CF65, CF75, CF85 Series . Manual - part 72

©

200338

1-1

Vehicle models

TECHNICAL DATA

ΧΦ65/75/85 series

0

0

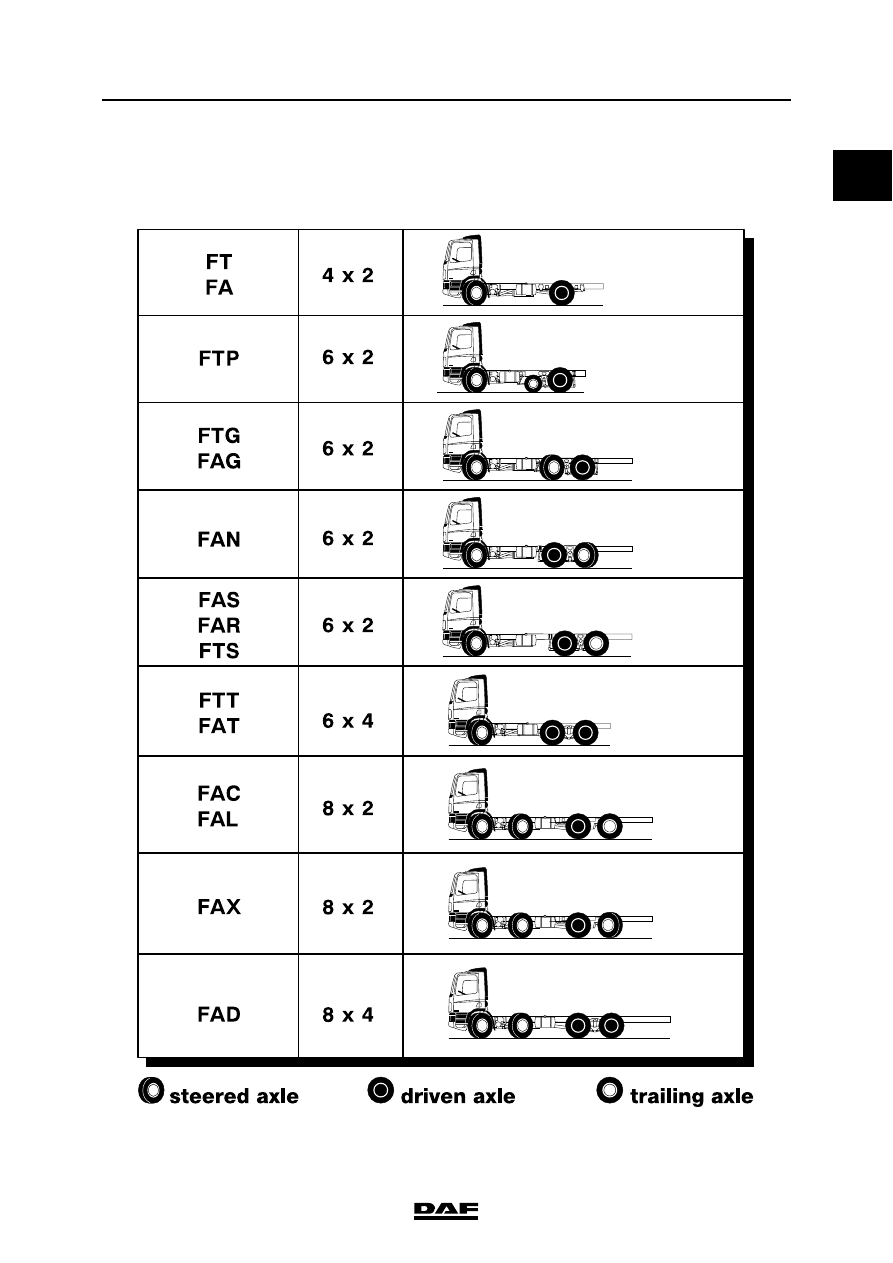

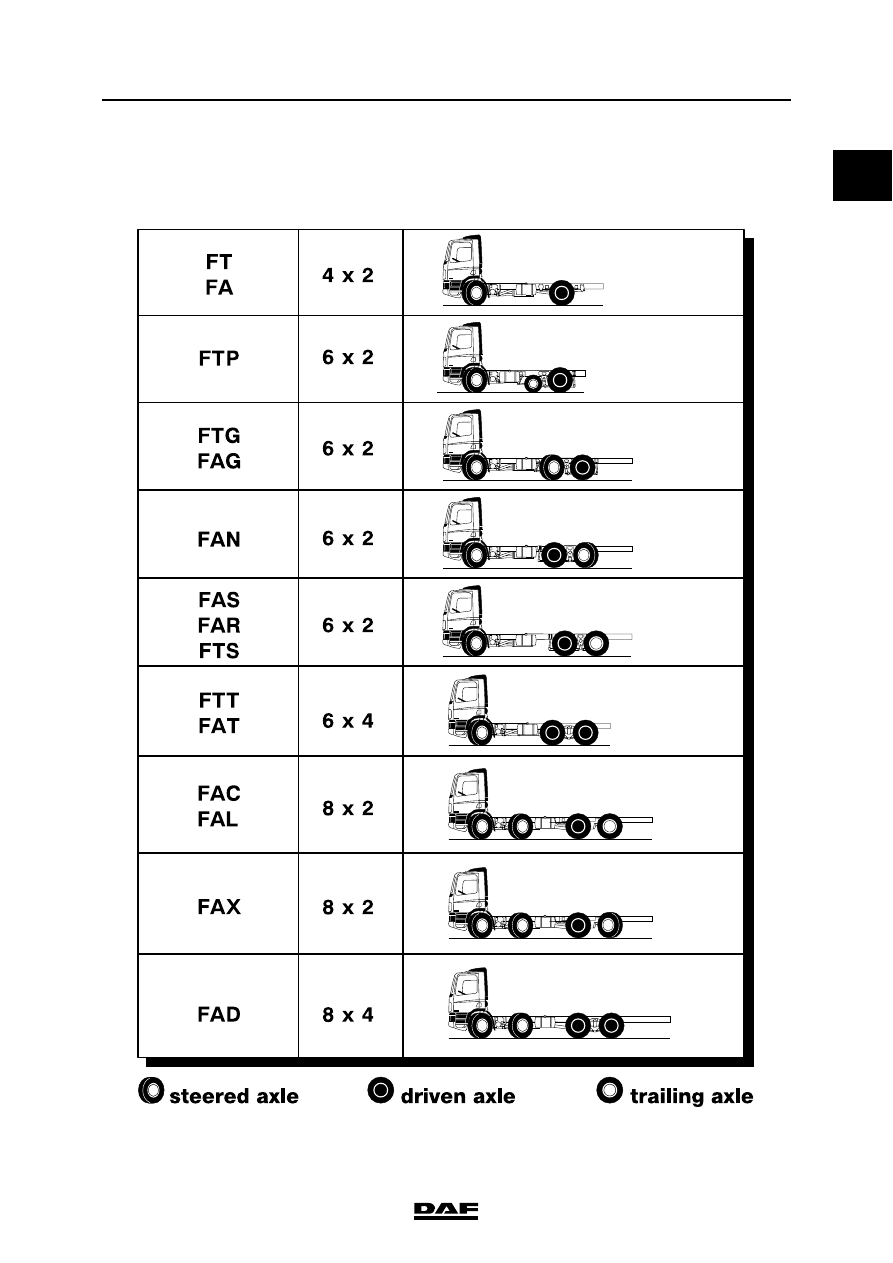

1. VEHICLE MODELS

1.1 OVERVIEW

G0 00 259

|

|

|

© 200338 1-1 Vehicle models TECHNICAL DATA ΧΦ65/75/85 series 0 0 1. VEHICLE MODELS 1.1 OVERVIEW G0 00 259 |