Chery Tiggo 5 (T21). Manual - part 130

08–

9

08

DIAGNOSIS & TESTING

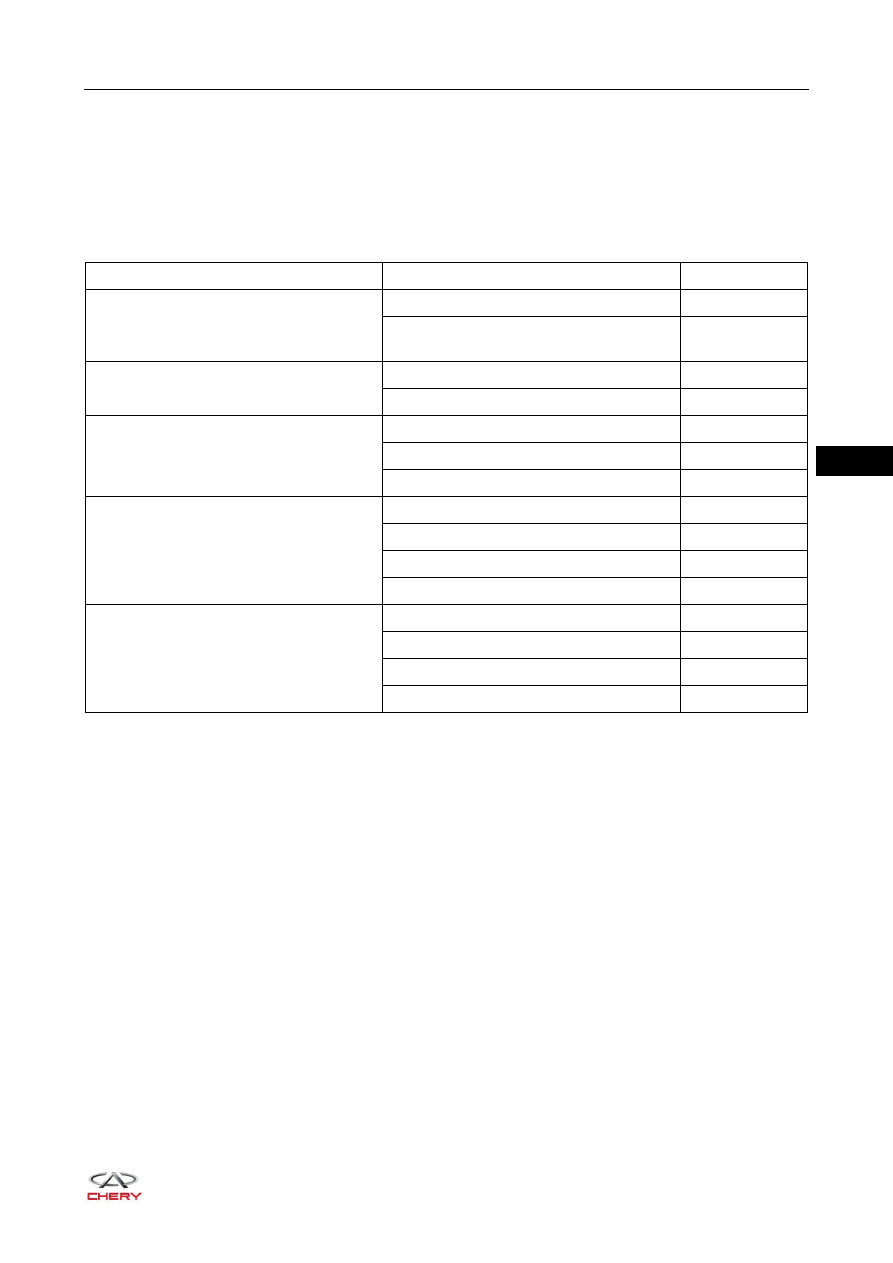

Problem Symptoms Table

HINT:

Use the table below to help determine the cause of problem symptoms. Check each suspected area in

sequence. Repair or replace the faulty components, or adjust as necessary.

Symptom

Suspected Area

See page

Fuel pressure in fuel supply system is too

low

Fuel filter assembly (blocked)

Electric fuel pump assembly (strainer

blocked)

Fuel pressure in fuel supply system is too

high

Fuel injector (clogged)

Electric fuel pump assembly

Electric fuel pump assembly has loud

operating noise and operates delay

Low fuel level

-

Electric fuel pump assembly relay

-

Electric fuel pump assembly

Injector is clogged and leaks

Fuel filter assembly (blocked)

Fuel injector

Poor fuel quality

-

Excessive foreign matter in fuel tank

-

Injector does not work

Fuel supply system line (broken)

-

Fuel injector (short in coil)

Electric fuel pump assembly (damaged)

Wire harness

-