Chery SQR 7160 sedan. Manual - part 128

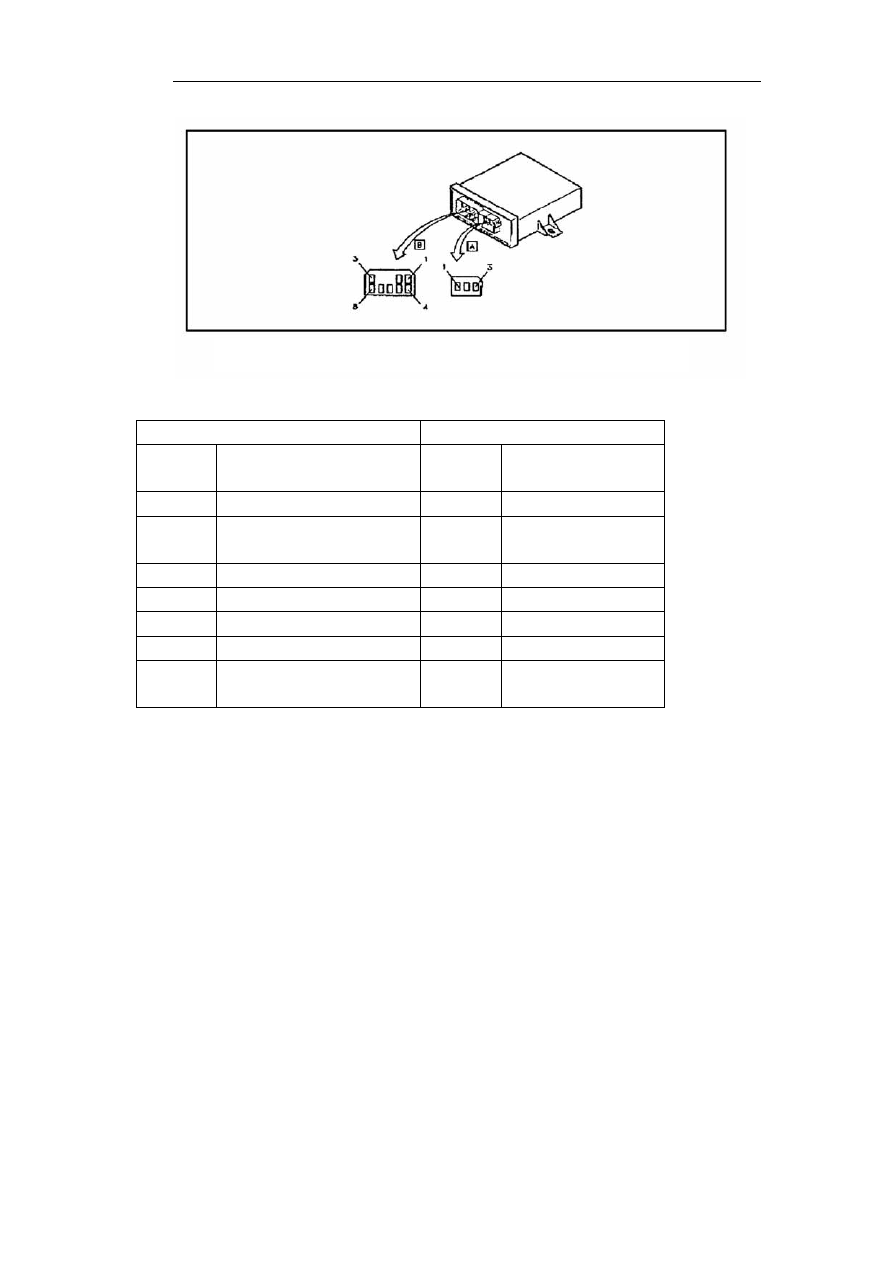

Fig 14 Anti-theft ECU

Anti-theft ECU pin definition

8-pin connector

3-pin connector

1 Not

used

1

Antenna

positive

2

warning indicator

2

not used

3 +30(12V)

3

Antenna

negative

4 ground

5 Not

used

6

to ECU serial surface

7 Not

used

8

+15 (ignition switch

positive)

Warning indicator

Warning indicator on instruments panel is controlled by anti-theft ECU, indicating user

state information. Warning indicator will flicker under following conditions:

1. The key is stored;

2. 2.5 seconds after the key turned on, the warning indicator begins to flicker, indicating

system is operating but engine will not be protected until the key is stored.

5. Electronic Control Fuel Injection System Maintenance

(1) Fuel

ONLY high quality vehicle unleaded gasoline of RESEARCH RULE octane value

RON90 or above (conform to SH0041 standard, lead content〈=0.005g/L〉, otherwise, the

electronic control fuel injection system and 3 way catalyst converter will be damaged,

affecting exhaust performance.. In addition, sulfur or lead can damage heated oxygen

sensor.

(2) Start-up

The electronic control fuel injection system can provide appropriate injection fuel width

under all conditions. Therefore depressing pedal is not necessary before or after hot or cold