Chery S11 / Chery QQ. Manual - part 236

Chery QQ Maintenance Manual 465 EFI System

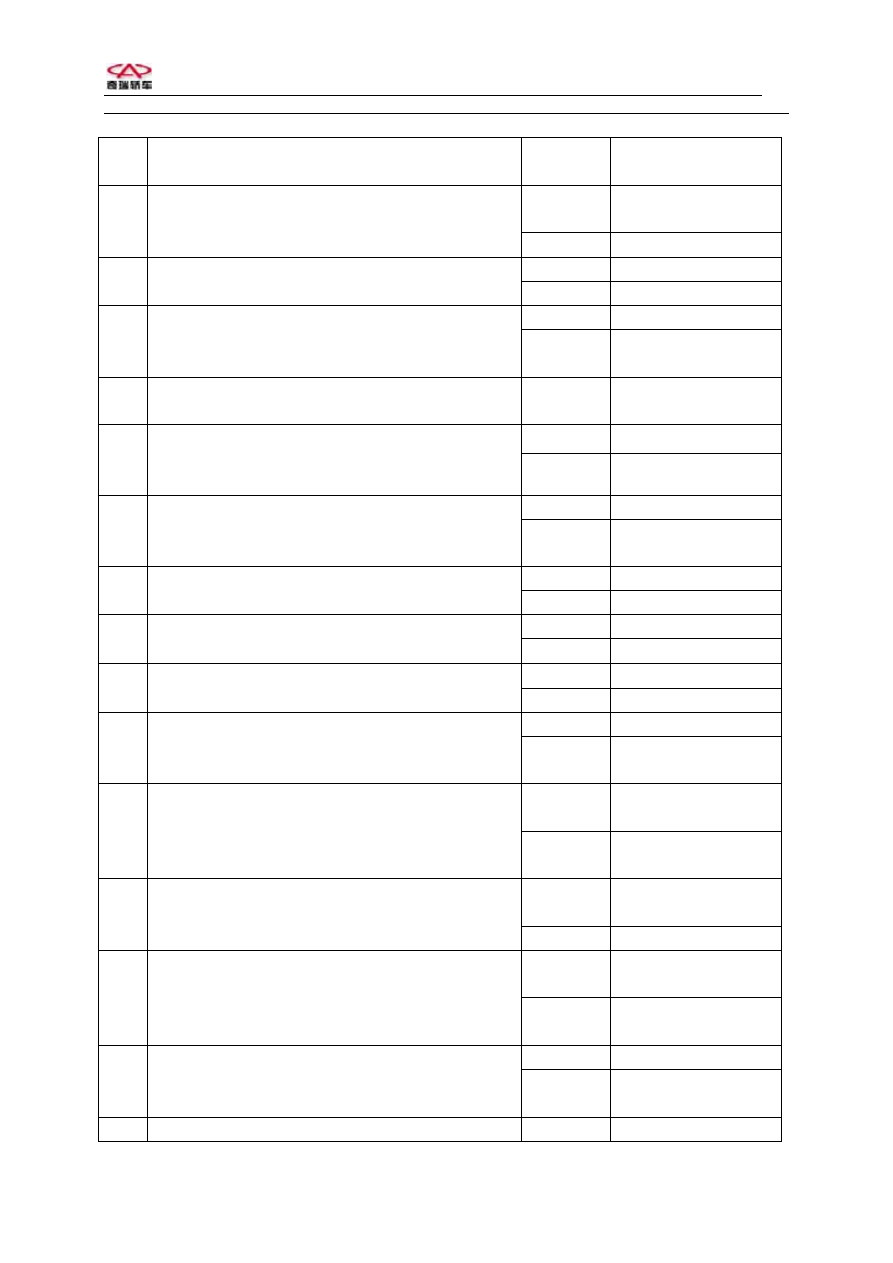

4) RPM is normal but difficult in starting

No. Operation

steps Test

results

Next step

Yes Eliminate

malfunction

1

Turn on ignition key. Use tester to check if

malfunction information record exists.

No Next

Yes Next

2

Check if air filter is through.

No Replace

Yes Next

3

Check if MAP pressure is 35—65 kPa at idle

after start.

No Eliminate

intake

system leak

4

Step down throttle slightly and check engine can

start easily.

Yes

Replace or check

throttle valve

Yes Next

5

Connect fuel pressure gauge valve. Short pin 30

on fuel pump relay and pin 87 to start fuel pump.

Check if fuel pressure is 250—300 kPa.

No 9

Yes 8

6

Use special connector to supply 12 V voltage

from battery to injector and check if injector

works normally.

No Next

Yes Next

7

Re-check if injector can inject fuel after cleaning.

No

Replace injector

Yes Replace

fuel

8

Replace fuel. Check If fuel deteriorates or

contains water.

No 14

Yes Next

9

Check if fuel pressure below 250kPa.

No 13

Yes Next

10 Shut off fuel gauge valve. Connect ignition key

again to run fuel pump for 3 seconds. Check if

fuel pressure can be set up.

No 12

Yes Replace

fuel

pressure regulator

11 Open fuel gauge valve, use return fuel blocker to

clamp fuel pipe for no returning fuel. Check if

fuel pressure can be set up soon.

No

Repair and replace

injector or fuel pipe

Yes

Repair and replace

fuel pipe

12 Connect fuel pessure gauge valve. Short pin 30

on fuel pump relay and pin 87 to start fuel pump.

Check if fuel pressure is 250—300 kPa

No

Replace fuel pump

Yes

Repair or replace

returning fuel pipe

13

Check returning fuel pipe is blocked or bend.

No

Replace fuel

prassure regulator

Yes Next

14 Pull out idle actuator connector before coolant

temperature reaches 35 C

and check if engine

speed is dropping.

No

Repair or replace

idle actuator

15 Yes

Next

41