Chery S11 / Chery QQ. Manual - part 66

Chery QQ Service Manual BCM Computer Control System

Horn button wiring broken or loose contact

thereof

Repair or replace

The sound of horn is

low

Insufficient charge of secondary cell

Horn defective

Interference between horn and direction

indicator lamp

Recharge or change the

cell

Replace

Adjust

After releasing the horn

button, the horn would

not stop

Short in the horn button

Replace

Repair

Ⅲ

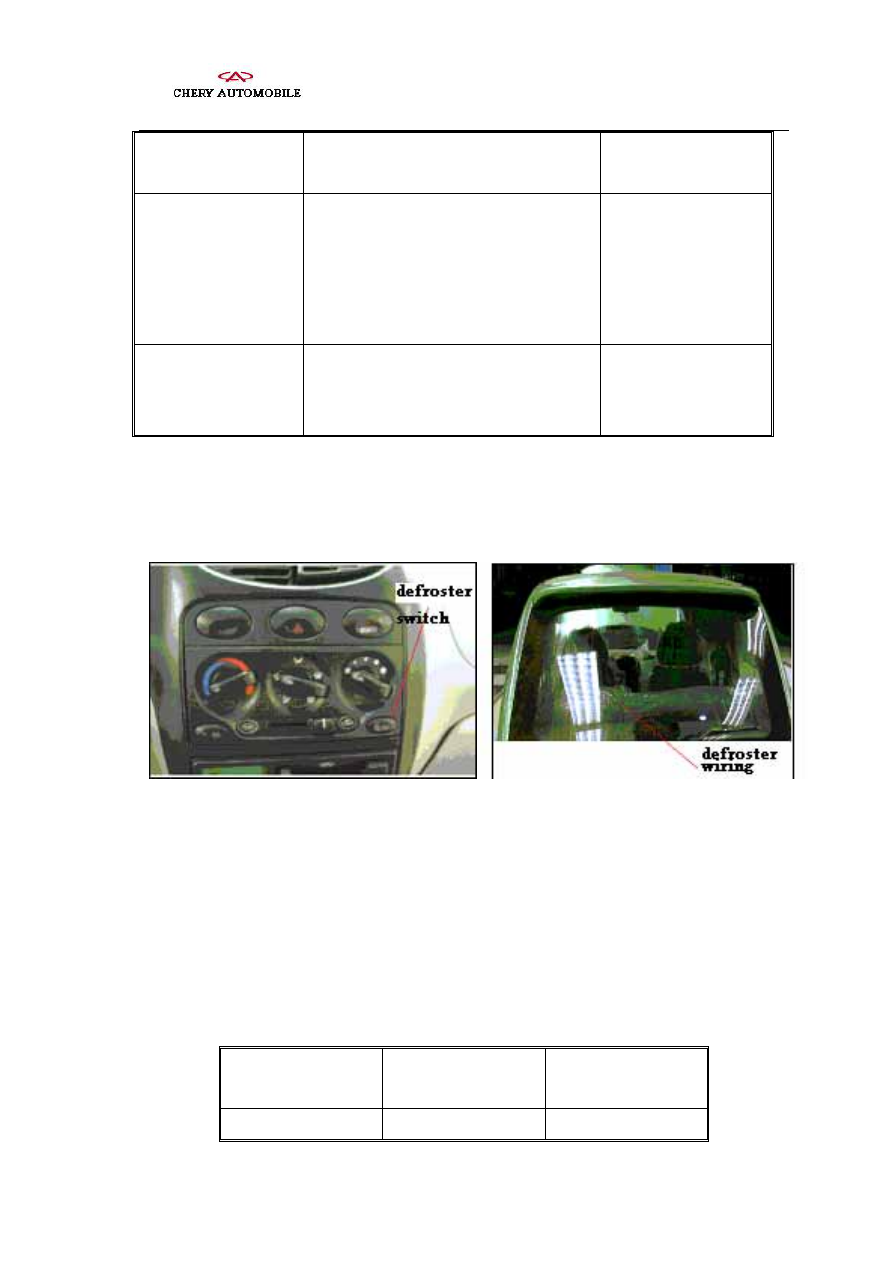

. Inspection and Repair of the Defrost System

In figure defrost system is schematically shown.

Schematic view of the defrost system

1、Inspection of the conduction of the defroster switch

As shown in the table, if it does not conform to the table, change the defroster

switch.

Inspection of the defroster switch

Switch position

Connection to the

instrument

Conductance

Switch OFF

-

No

- 108 -