Chery S11 / Chery QQ. Manual - part 12

Chery QQ Service Manual Transmission System

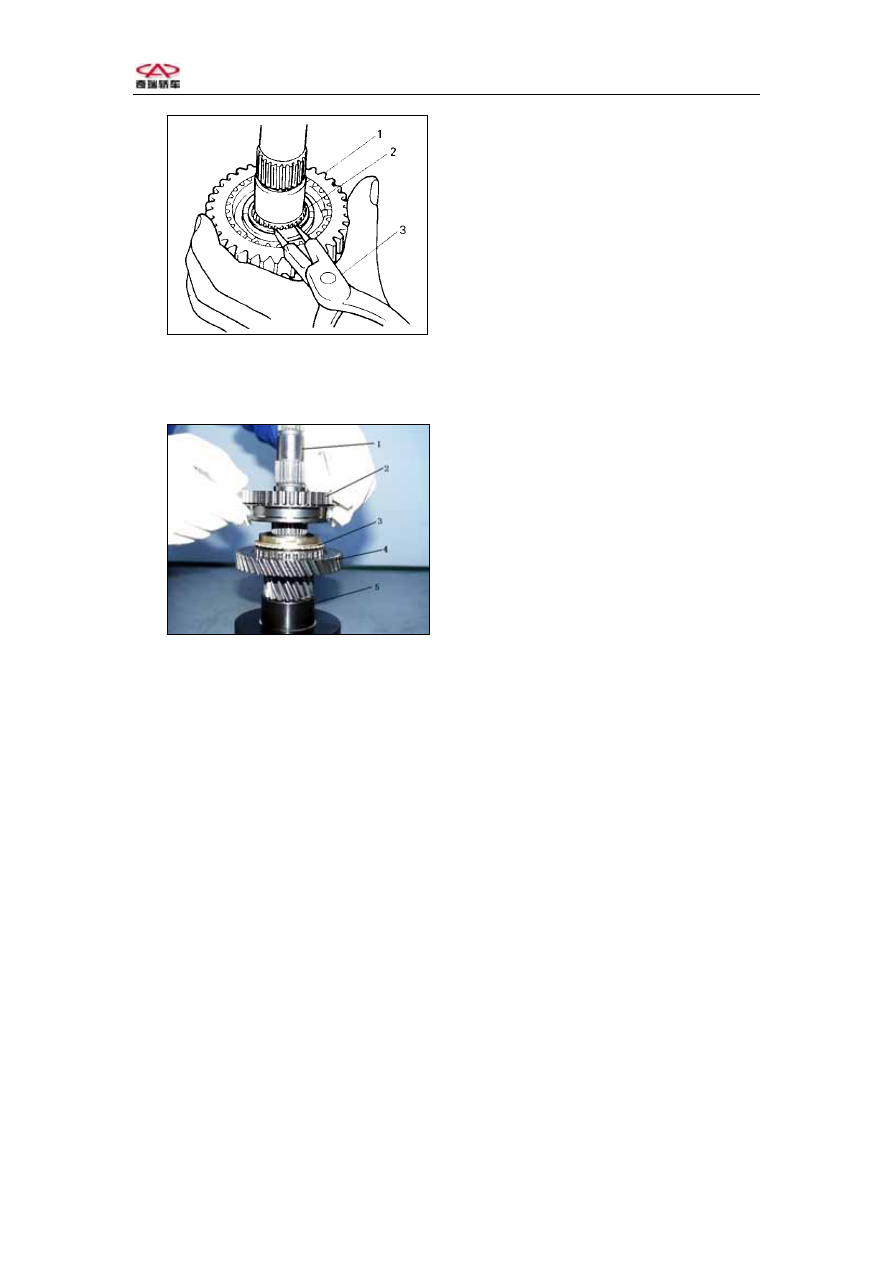

1- Hub sleeve outer race

2- Snap ring

3- Special tool

Fig.3-33

5. Remove the synchronizer assembly, 1st Synchronizer ring.

6. Remove the 1st driven gear and needle roller bearing.

1, Output shaft

2, Hub sleeve outer race

3, 1st synchronizer ring

4, 1st driven gear

5, Special tool

Fig.3-34

Check and re-install:

1.Clear up all the parts, check if there is anything abnormal, if necessary, change

the used parts.

2.If the synchronizer need repair, first check the clearance “a” between

synchronizer ring and gear and the clearance between the angle and hub, and then

decide if changed the used parts.

-69-