Chery A15. Manual - part 193

Chery A15 Maintenance Manual

Perform coating according to “Coating process

for steel plate” in this chapter.

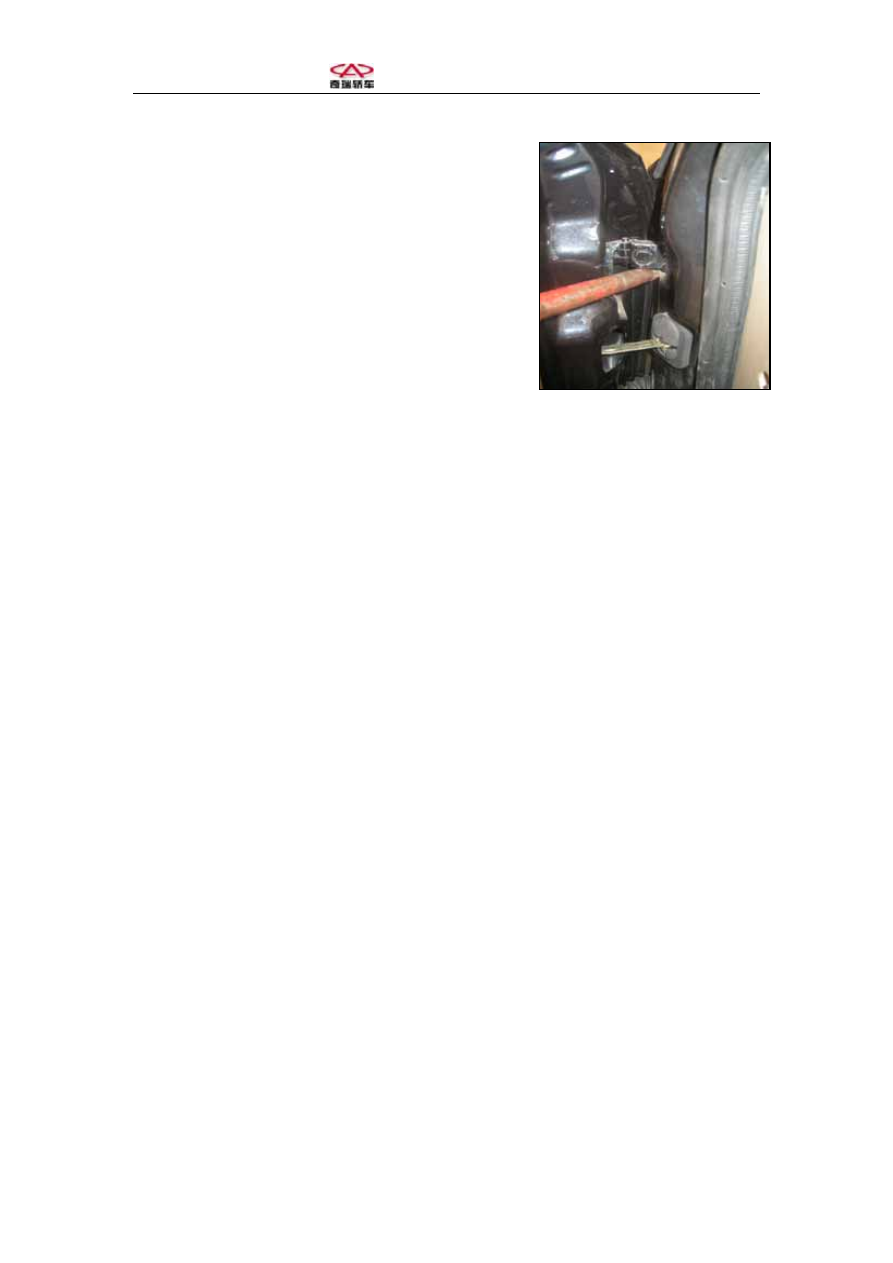

In case that longitudinal or transverse

adjustment of the front door is necessary, use tools

for adjusting internal hinge to loosen the hinged bolts

on the hinge with specified pressure, in a direction

parallel with the level. Loosening should be performed

in a slow way otherwise material fatigue may occur. Don’t

move the tools longitudinally for damage caused

by this can only be remedied through re-welding

the hinge. In order to avoid cracks on coating of

vehicle, coating wax should be applied on paint coat.

Tighten the door after adjusting it with

tightening torque of 56N.m.

Note:

After closing the door, keep the door sealed with

the sealing strips around the opening of the door.

If there aren’t any holes on the sealing strips to

allow air in, or the door is subject to overpressure

when closing, the door might not be able to be closed

due to improper pressure.

Remove any of the following parts after the door

guard plate has been removed. Then proceed

according to the instructions in “Inner lining and

decoration”.