Chery A15. Manual - part 98

The quality of spray coating process for surface protective layer plays a decisive part for the

quality of anticorrosive function with protective layer. The processes include.

1. General cleaning, and coating with phosphate.

2. General spray coating with alkyl ester-based paint.

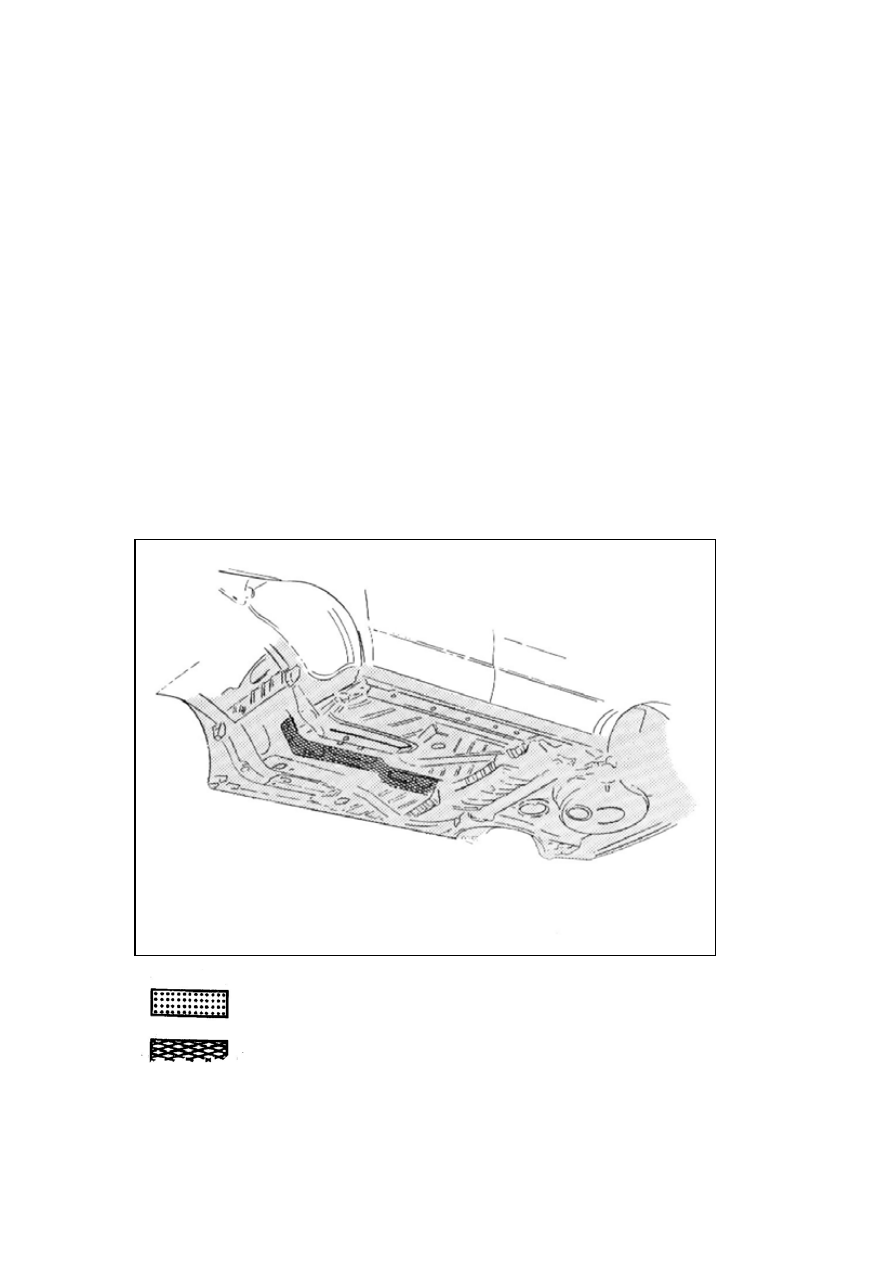

3. PVC gel is sprayed at the joints of body, to prevent leakage, and PVC gel is also to be

sprayed for the lower plate underneath the car body (such as gear case, the lower plate of

car body, door sill, and other places), to prevent the general assembly from damage of

sandstones.

4. Primer is to be spray coated through static electric system, as the second protective layer.

5. According to the principle for optimal efficiency, lacquer enamel shall be sprayed one or

two times (as primer or cleaning coat) through static system.

6. Protection wax is to be sprayed in the open area of the general assembly through timed

spraying system.

PROTECTION OF UNDERBODY PANEL

PVC

Lacquer Putty

S-42