Loader Bobcat 853, 853H. Manual - part 60

FAN GEARBOX (Cont’d)

Checking Backlash (Cont’d)

When the backlash is correct, install the seals, cap and

gear oil as follows:

Remove the bolts from the flanges and separate the two

housings.

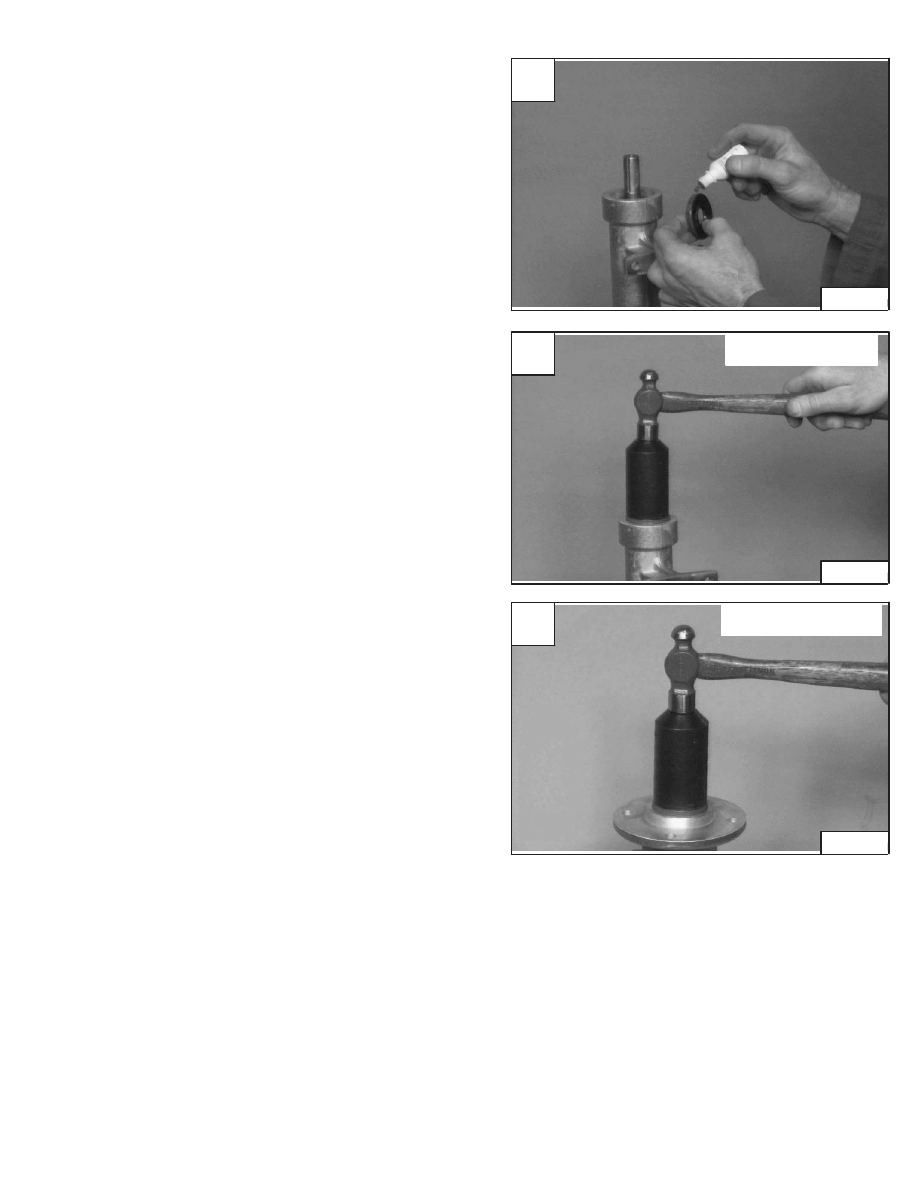

Put liquid adhesive (LOCTITE #242) on the outside

diameter of the seal(s) [A].

Install the seal(s) flush with the housing surface [B] & [C].

Clean any oil from the flange surface.

Install the long housing on the short housing flange.

Install the four bolts and part number tag.

Install and tighten the nuts to 25–28 ft.–lbs. (34–38 Nm)

torque.

A

P–03089

C

P–02986

SHORT HOUSING

853, 853H Loader

–7–29–

Service Manual

B

P–02985

LONG HOUSING