Haima M3. Service Manual - part 5

Electronic Fuel Injection Control System 1B

-

16

multimeter, and analogue multimeter shall not be

used to inspect the electronic fuel injection

system’s lines.

3. In the case of overhauling the vehicle with

anti-theft system, if the ECU will be replaced,

programming to ECU shall be done after the

replacement.

4. If the fault code indicates that a given circuit has

too low voltage, it means that there likely exists short

circuit to the earth in the circuit. If the fault code

indicates that a given circuit has too high voltage, it

means that there likely exists short circuit to the

battery in the circuit. If the fault code indicates that

there is fault at a given circuit, it means that there

likely exists open circuit or several types of faults in

the circuit.

Diagnosis help:

1. If the fault code cannot be cleared, the fault

belongs to “Steady-state” fault. If the fault belongs

to sporadic fault, emphasis should be put on the

inspection to wiring connector’s looseness.

2. No abnormal situation after preceding

inspection;

3. During the overhaul process, do not overlook

other factors’ influence on the system, such as

automobile maintenance, cylinder pressure, and

mechanical ignition timing etc.

4. Replace ECU for further test.

If the fault code can be cleared, the fault cause

should be attributed to ECU. However if the fault

code cannot be cleared, remount original ECU and

repeat the workflow for further overhaul work.

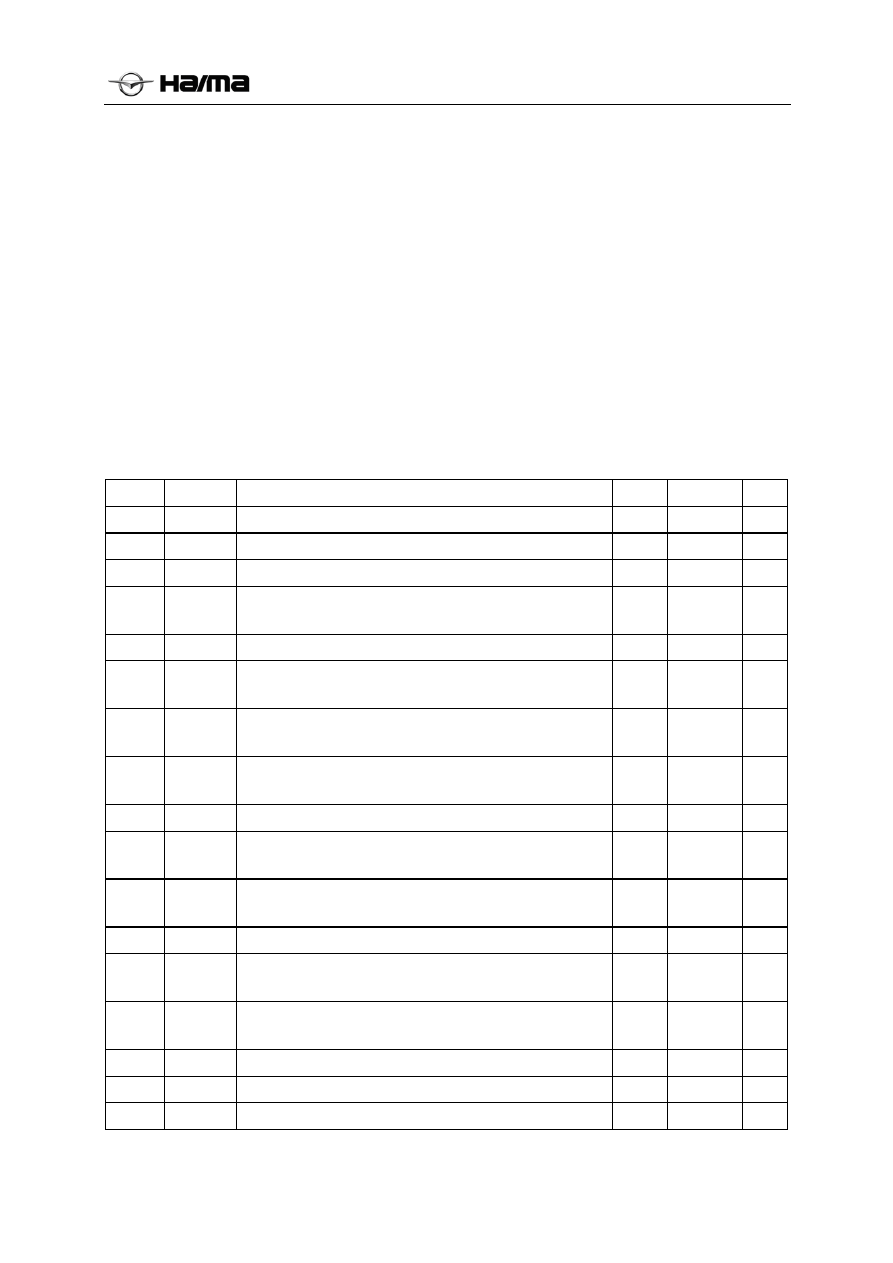

INDEX PCODES

UAES Explanations

CLASS MIL

SVS

1

P000A

Slow intake VVT response

5

×

×

2

P000B

Slow exhaust VVT response

5

×

×

3

P0010

VVT intake control valve circuit, open

3

√ ×

4 P0012

Intake VVT fails to stay at defaulted position when

starting

5 × ×

5

P0013

VVT exhaust control valve circuit, open

3

√ ×

6 P0015

Exhaust VVT fails to stay at defaulted position when

starting

5 × ×

7 P0016

Improper relative position between crankshaft and

camshaft

3

√ ×

8 P0017

Improper relative position between crankshaft and

camshaft

3

√ ×

9

P0030

Upstream oxygen sensor heater control circuit, fault

3

√ ×

10 P0031

Upstream oxygen sensor heater control circuit, low

voltage

3

√ ×

11 P0032

Upstream oxygen sensor heater control circuit, high

voltage

3

√ ×

12

P0036

Downstream oxygen sensor heater control circuit, fault

3

√ ×

13 P0037

Downstream oxygen sensor heater control circuit, low

voltage,

3

√ ×

14 P0038

Downstream oxygen sensor heater control circuit, low

voltage

3

√ ×

15

P0053

Upstream oxygen sensor heater resistance, improper

3

√ ×

16

P0054

Downstream oxygen sensor heater resistance, improper

3

√ ×

17

P0105

Intake pressure sensor signal, no fluctuation (freezing)

3

√ ×