Saturn Transmission. Manual - part 22

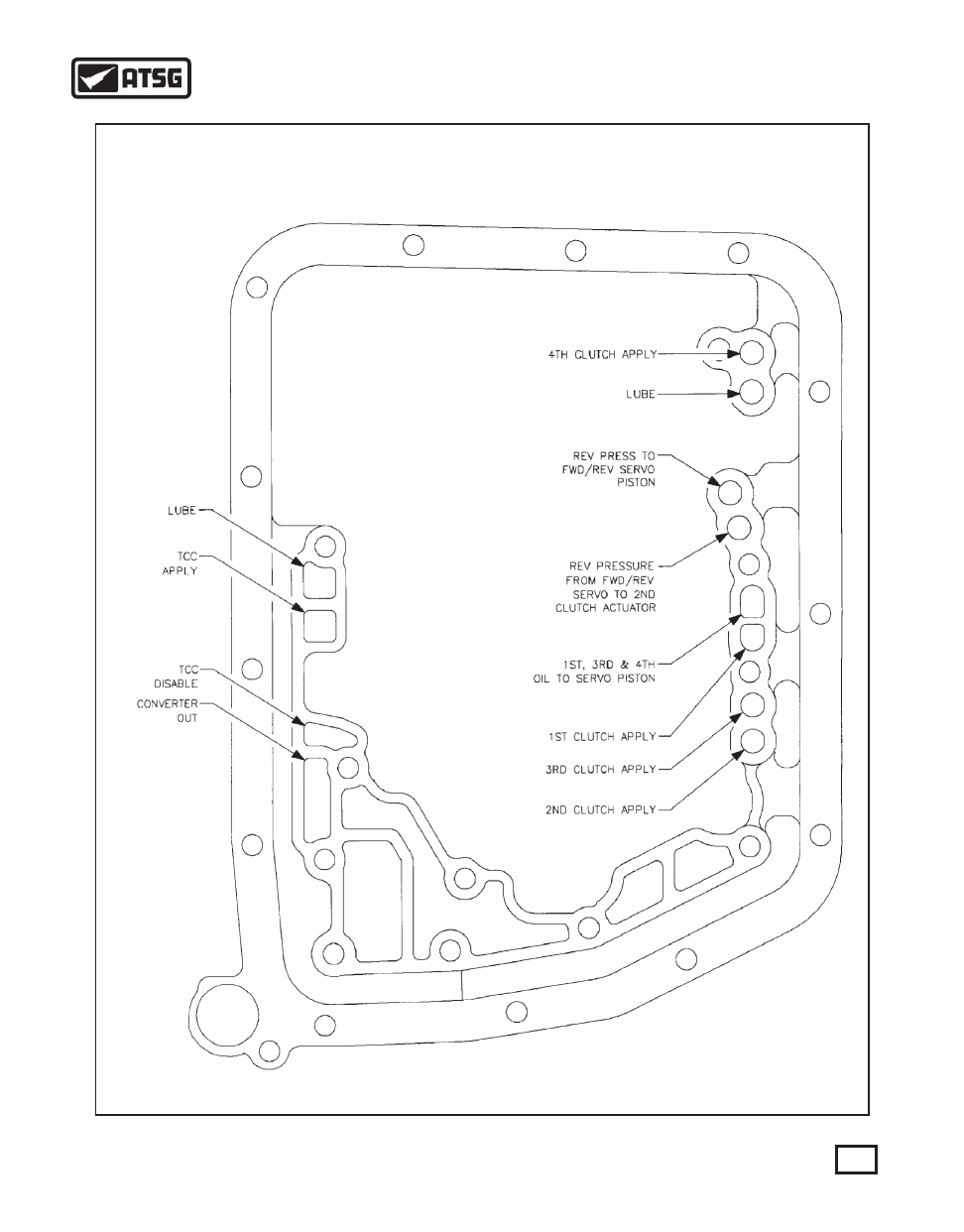

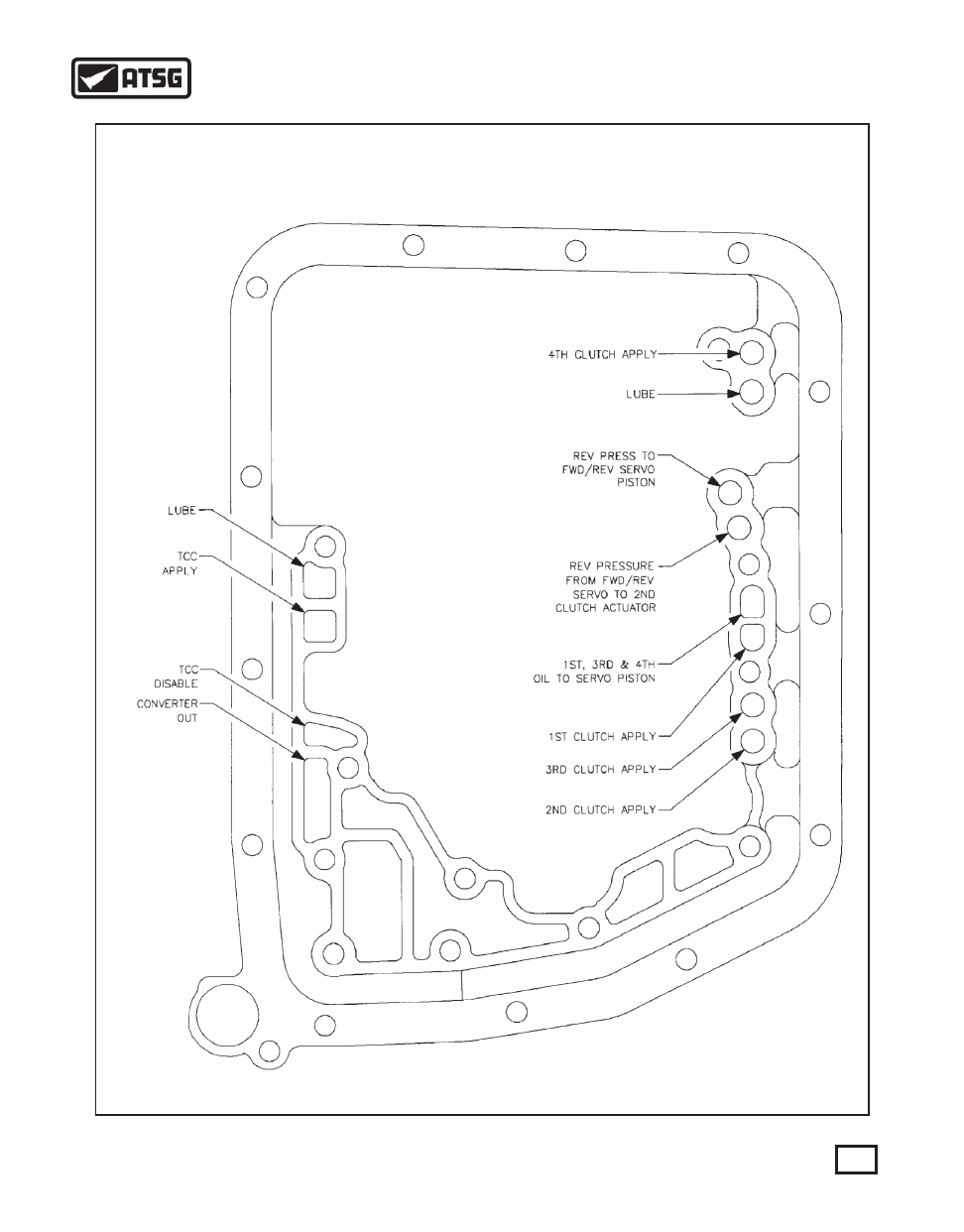

AIR PRESSURE TEST PORTS

2ND DESIGN CASE

91

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

|

|

|

AIR PRESSURE TEST PORTS 2ND DESIGN CASE 91 AUTOMATIC TRANSMISSION SERVICE GROUP Technical Service Information |