Porshe 911 (997). Manual - part 30

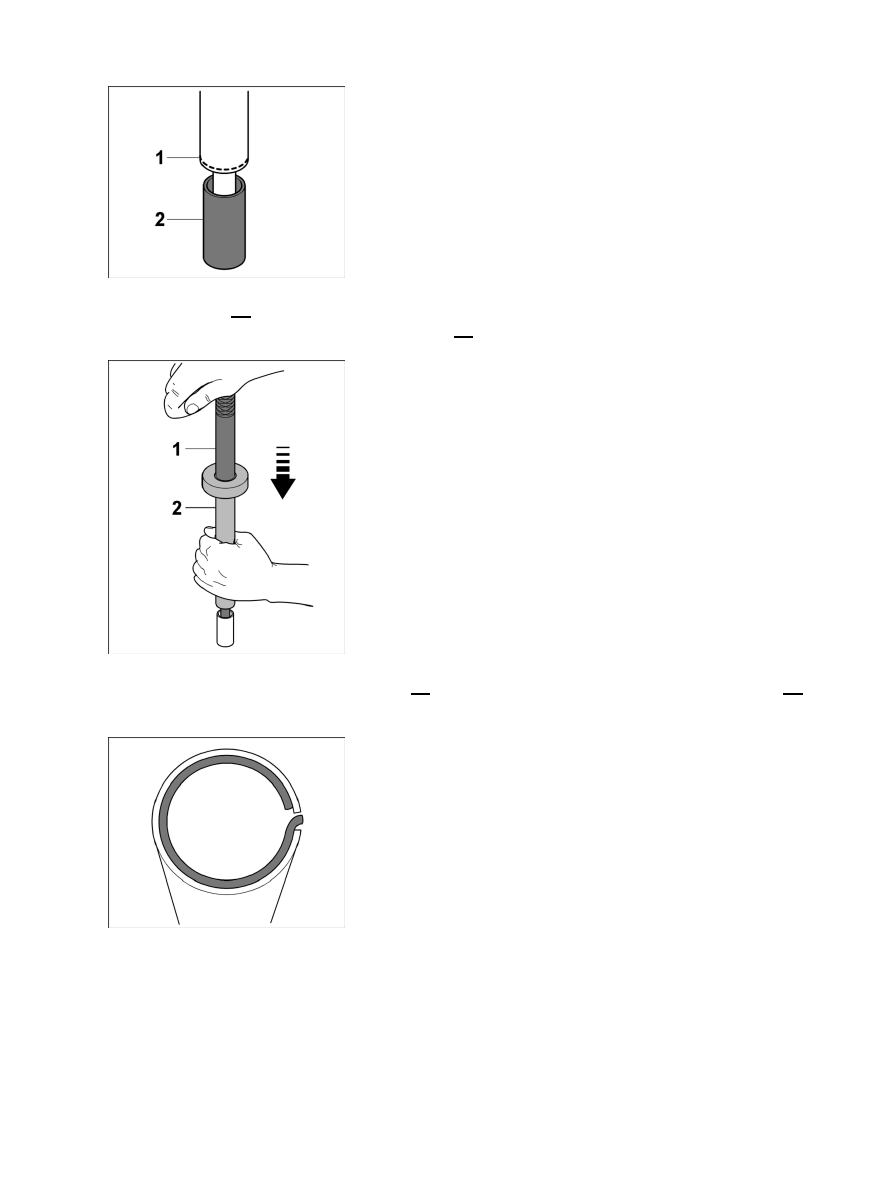

Assembly tool on piston pin

43. Oil piston pin -3- with new engine oil and place it in an upright position on a clean surface on the

workbench. Position assembly tube with circlip -1- and pressure pin on piston pin.

Moving piston-pin circlip into installation position

44. Press piston-pin circlip with pressure pin -1- onto piston pin; while doing so, press assembly tube -2-

firmly onto piston pin. This will move the piston-pin circlip into the correct installation position.

Installation position of piston-pin circlip in assembly tube

45. Check installation position of piston-pin circlip in assembly tube.

Diagnostic system: reading out fault memory and activating systems

Installing pistons

277