Engine International HS 2.8L. Manual - part 11

International HS 2.8L

Cylinder Head

5 1

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

Reinstallation

1.

Make sure that the engine block surface is

perfectly clean.

2.

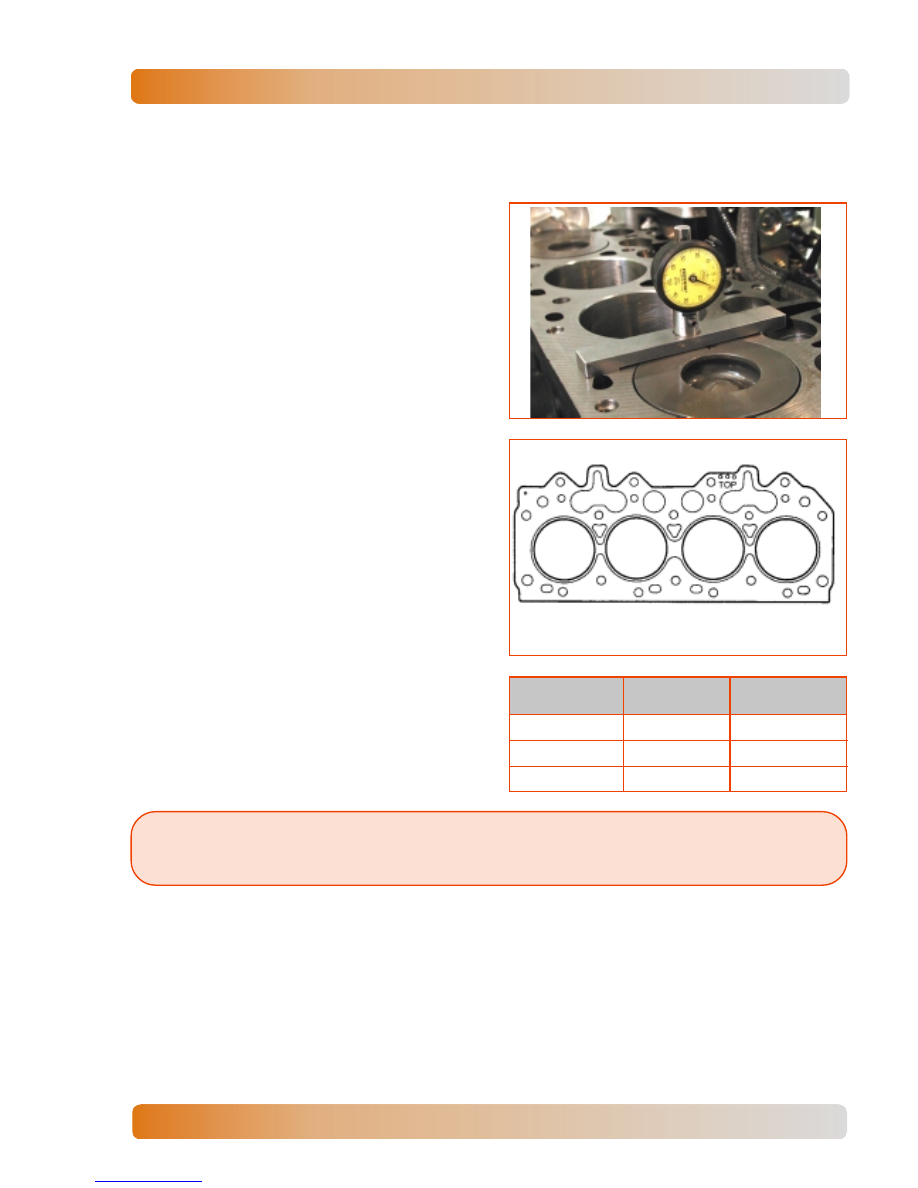

Using a dial indicator gauge with a magnetic

base, check pistons height, to specify the

cylinder head gasket.

3.

There are available 3 (three) types of gaskets

for the cylinder head assembly, identified by

holes in the left side, from front viewing.

Note:

Cylinder head gasket corresponds to piston height, in relation with cylinder head

surface.

4.

Select a new gasket with the correct

thickness.

Holes

reference

Gasket

thickness

Piston Height

(mm)

0

1.37 mm

from 0.50 to 0.60

00

1.48 mm

from 0.61 to 0.70

000

1.59 mm

from 0.71 to 0.80