Kubota tractor (BX25DLB-AU, LA240A, LA240A, AU-SG, BT602). OPERATOR'S MANUAL - part 28

81

PERIODIC SERVICE OF THE TRACTOR

B

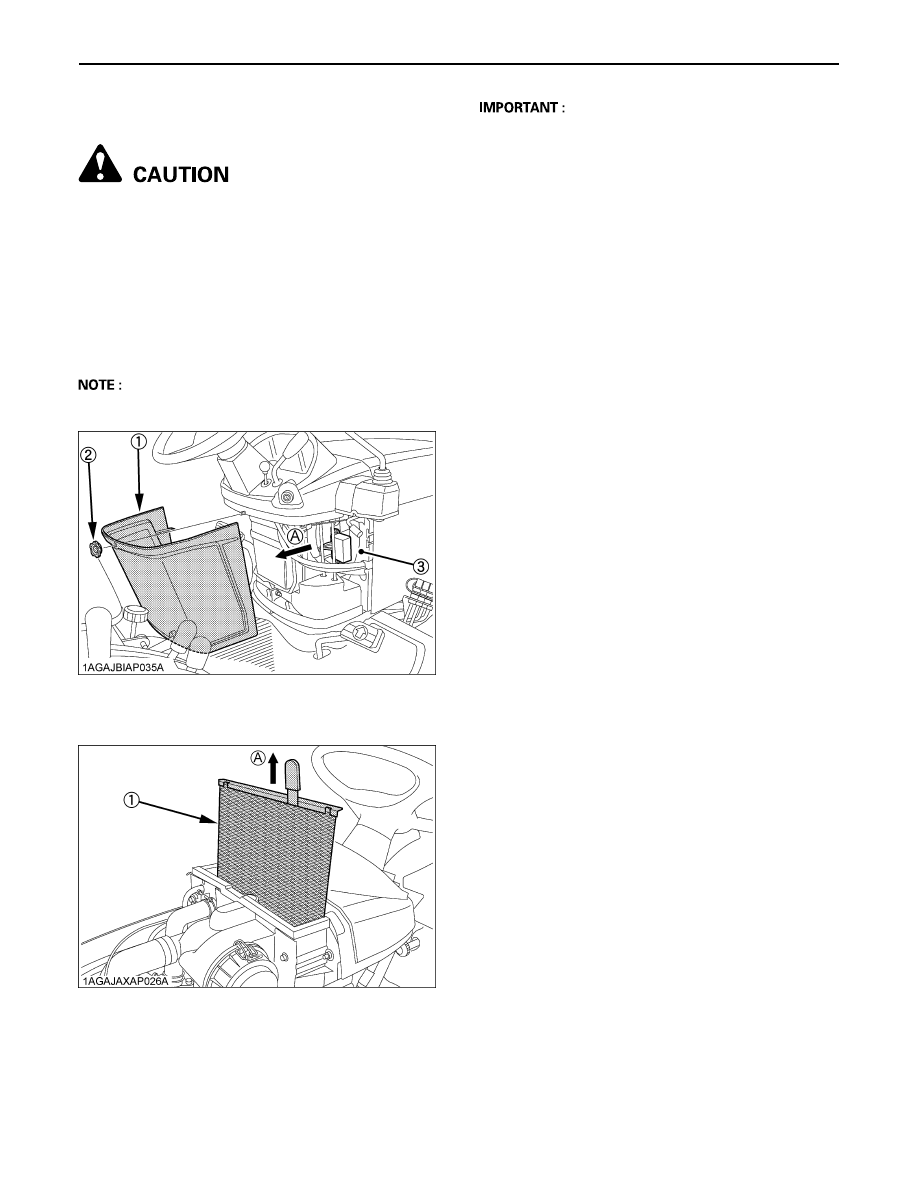

Cleaning Panel and Radiator Screen

To avoid personal injury:

A

Be sure to stop the engine and remove the key

before removing the screen.

A

Before checking or cleaning it, wait long

enough until it cools down.

1. Check panel screen to be sure they are clean from

debris.

2. Detach the radiator screen, and then remove all the

foreign material.

A

If the dust or chaff is accumulated in the battery

compartment, open the panel and clean completely.

A

Panel and radiator screen must be clean from debris

to prevent engine from overheating and to allow good

air intake for air cleaner.

A

Be sure to reinstall the panel on the pillar completely

to prevent the invasion of dust.

A

Be sure to stop the engine to avoid personal injury and

to allow good air intake for air cleaner.

B

Checking Brake Pedal

1. Inspect the brake pedal for free travel, and smooth

operation.

2. Adjust if incorrect measurement is found:

(See "Adjusting Brake Pedal" in "EVERY 100 HOURS"

in "PERIODIC SERVICE OF THE TRACTOR"

section.)

B

Checking Gauges, Meters and Easy

Checker(TM)

1. Inspect the instrument panel for broken gauge(s),

meter(s) and Easy Checker(TM) lamps.

2. Replace if broken.

B

Checking Head Light, Hazard Light etc.

1. Inspect the lights for broken bulbs and lenses.

2. Replace if broken.

B

Checking Seat Belt and ROPS

1. Always check condition of seat belt and ROPS

attaching hardware before operating tractor.

2. Replace if damaged.

(1) Panel

(2) Knob

(3) Center pillar

(A) "DETACH"

(1) Radiator screen

(A) "DETACH"