Snowmobile Arctic Cat 2-Stroke (2007 year). Manual - part 101

8-24

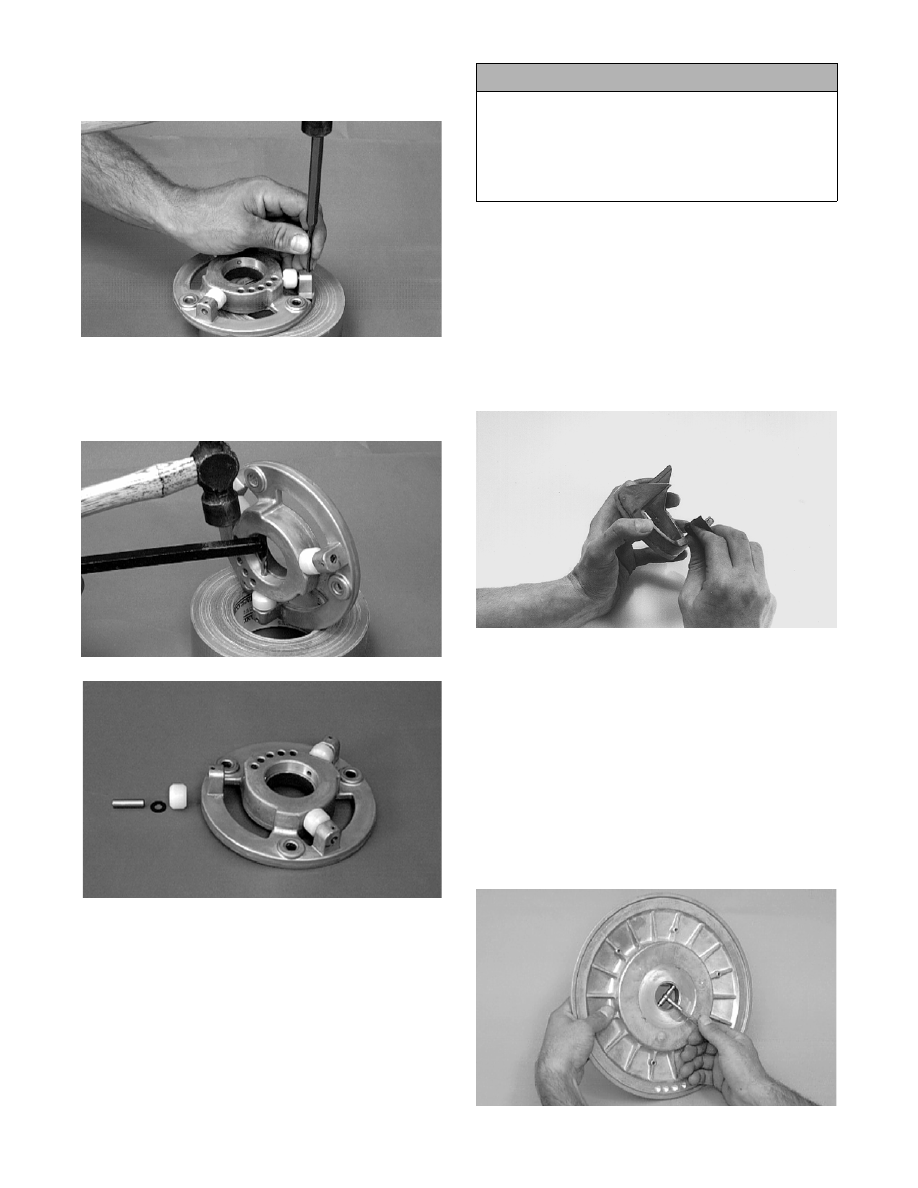

8. Using a 1/8-in. punch, remove the spring pin

securing the roller, roller pin, and thrust washer to

the plate.

SC005D

9. Using the Roller Pin Removal Tool (p/n 0644-276)

from inside the plate, drive the roller pin out of the

plate. Account for the pin, thrust washer, and

roller.

SC006D

SC007D

CLEANING AND INSPECTING

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is

necessary.

1. Using parts-cleaning solvent, wash grease, drive

belt dust, and foreign matter off all components.

2. Inspect the rollers for damage, cracks, or wear.

3. Inspect the sheaves for any gouges, cracks, or

other damage. Also, inspect threaded areas of

sheaves for damaged or stripped threads.

4. Inspect the torque bracket (cam) for cracks or

damage. The ramp portions of the bracket and

caps must be free of gouges and damage. Minor

scratches may be repaired using #320 grit wet-or-

dry sandpaper.

B465

5. Inspect spring for distortion, crystallization, or

breaks.

6. Inspect the roller plate, rollers, pins, and spring

mounting holes for cracks, damage, or wear.

7. Inspect the roller plate and movable sheave bear-

ings for wear. For each respective bearing, mea-

sure the outside diameter of the shaft and the

inside diameter of the bearing. Compare the read-

ings. Clearance between the shaft and the respec-

tive bearing must not exceed 0.5 mm (0.020 in.). If

the clearance exceeds the specification, the bear-

ing must be replaced.

B466D

! CAUTION

Do not use steel wool or a wire brush to clean driven

pulley components. A wire brush or steel wool will

cause the sheaves to be gouged (thus, the drive belt

may not slide properly between sheaves). Decreased

performance and possible accelerated drive belt

wear will result.