Snowmobile Arctic Cat 2-Stroke (2007 year). Manual - part 47

2-174

13. Install the throttle body assembly and secure with

the flange clamps; then connect the oil pump con-

trol rod and the oil hose.

FS209A

FS179A

NOTE: Check to be sure the mark on the control

arm is aligned with alignment mark on the oil-

injection pump boss in the full-open position. If the

marks are not aligned, adjust synchronization by

loosening the jam nuts on the adjuster. Rotate the

jam nuts/adjuster nut until proper alignment is

attained. Tighten jam nuts.

NOTE: When the cable/linkage adjusting nut is

adjusted correctly, the throttle lever will move

approximately 3.2 mm (1/8 in.) before the oil-injec-

tion pump arm begins to move.

14. Remove the oil bleed plug from the oil injection

pump. When oil flows from pump free of air bub-

bles and the hose is full of oil, install the oil bleed

plug and tighten.

NOTE: It is advisable to place a cloth beneath the

oil-injection pump to contain any oil spilled during

the bleeding process.

15. Connect the two throttle body coolant hoses to the

PTO-side and MAG-side throttle body and secure

with the clamps.

FS198A

16. Apply a thin coat of high-temperature silicone

sealant to each exhaust port; then install the

exhaust gaskets.

17. Apply a thin coat of high-temperature silicone

sealant to the mating surfaces of the exhaust mani-

fold; then install the exhaust manifold and secure

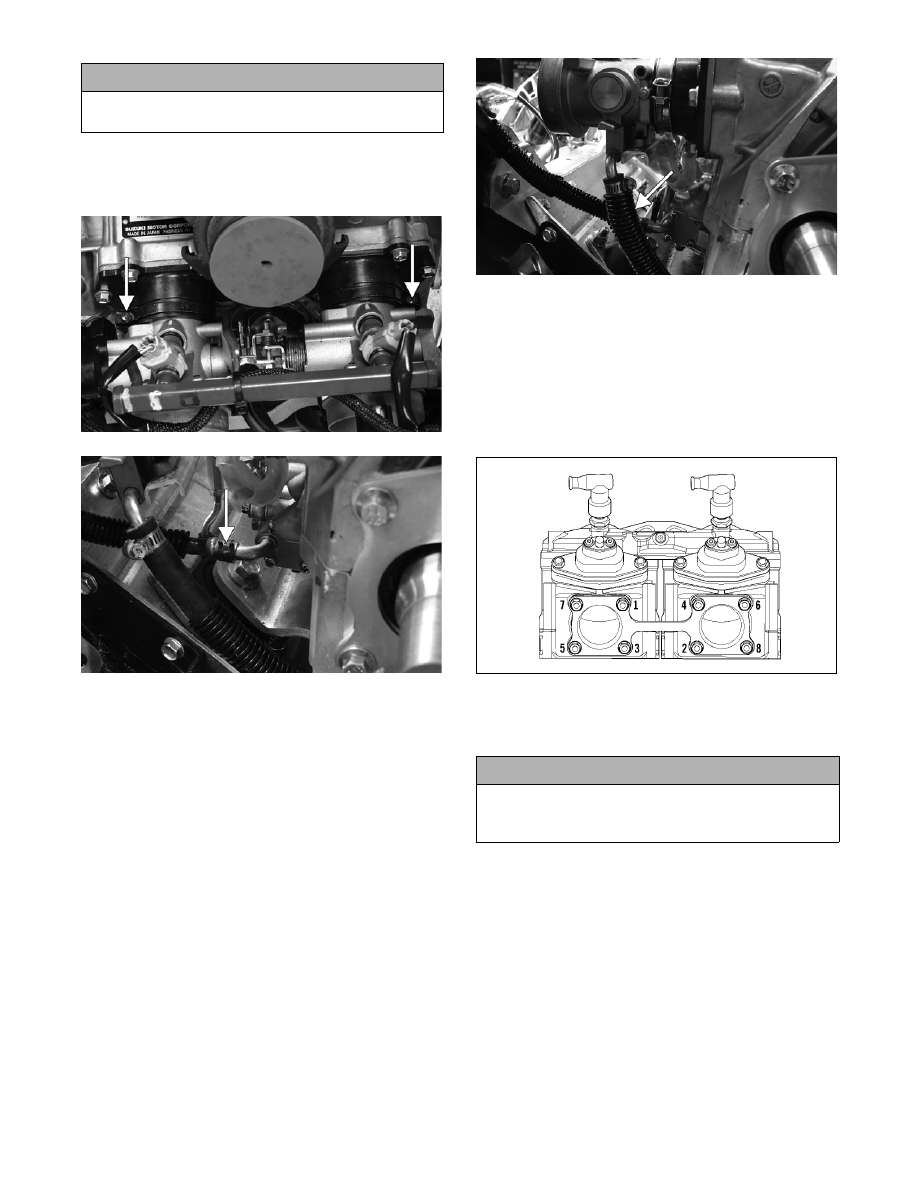

with the eight nuts. Using the pattern shown,

tighten to specifications.

0742-292

18. Route the gasline hose to the throttle body assem-

bly and secure the hose to the fuel rail. Tighten the

clamp securely.

19. Connect the coolant overflow hose to the cylinder

head; then connect the spark plug wires to the

spark plugs.

NOTE: On the 800 cc, connect the knock sensor

wiring to the wiring harness; then secure the con-

nector to the coolant filler neck bracket with the

push-mount cable tie.

! CAUTION

If the bracket/starter motor lock nut was loosened for

installing purposes, tighten the lock nut securely.

! CAUTION

When installing the throttle bodies, make sure the

gasline hose is properly routed to avoid premature

wear and/or contact with exhaust components.