Snowmobile Arctic Cat (2007 year). Manual - part 126

9-119

9

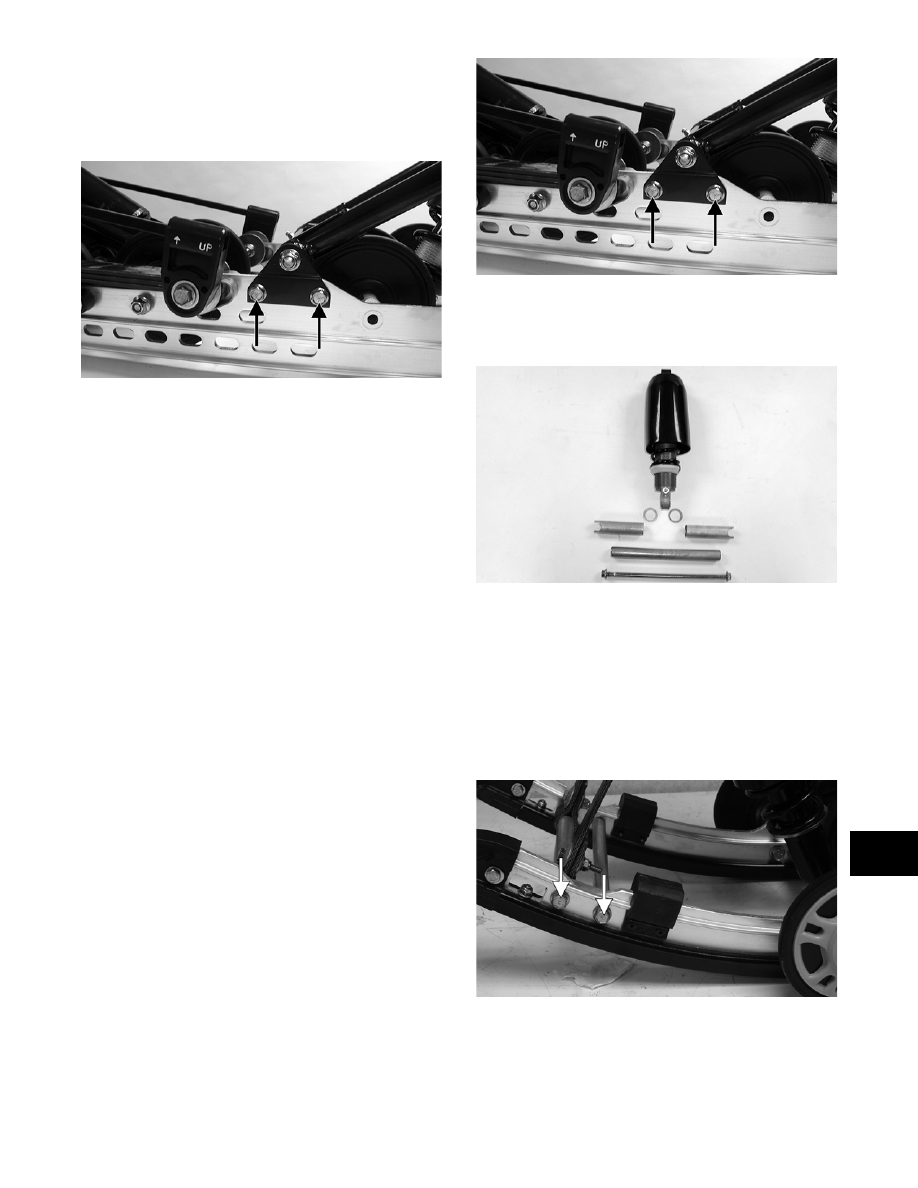

9. Move the rear arm assembly rearward far

enough to gain access to the front arm mounting

bracket lock nuts; then remove the cap screws

and lock nuts securing the brackets to the slide

rails.

MS106A

INSPECTING

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is

necessary.

1. Inspect all front arm weldments for cracks or

unusual bends; then inspect the front arm

mounting brackets for cracks and for elongated

holes.

2. Closely inspect all tubing for cracks or unusual

bends.

3. Inspect the bearings, bushings, and front arm

spacers for wear or damage.

4. Inspect the shock absorber for damage and for

any signs of oil leakage especially at the point

where the shock shaft enters the shock body.

5. Inspect the shock absorber eyelet welds (at each

end) for any cracks, signs of separation, or for

unthreading.

INSTALLING

1. Install the front arm mounting brackets to the

slide rails. Secure with cap screws and lock nuts

tightened to specifications.

MS106A

2. Install the axle into the lower shock eyelet bush-

ing assembly; then install the two spacers and

the two shim washers.

MS167

3. Place the front arm shock axle assembly into

position on the skid frame making sure the spac-

ers and washers are properly positioned. Secure

with the cap screw, washer, and a new lock nut.

Tighten to specifications.

NOTE: If the front rail support cap screws were

loosened (after step 8), treat the threads with blue

Loctite #243 and tighten to specifications.

ZJ275A

4. Position the front arm with bushings into the

mounting brackets. Secure with cap screws and

lock nuts. Tighten to specifications.