Snowmobile Arctic Cat (2007 year). Manual - part 120

9-95

9

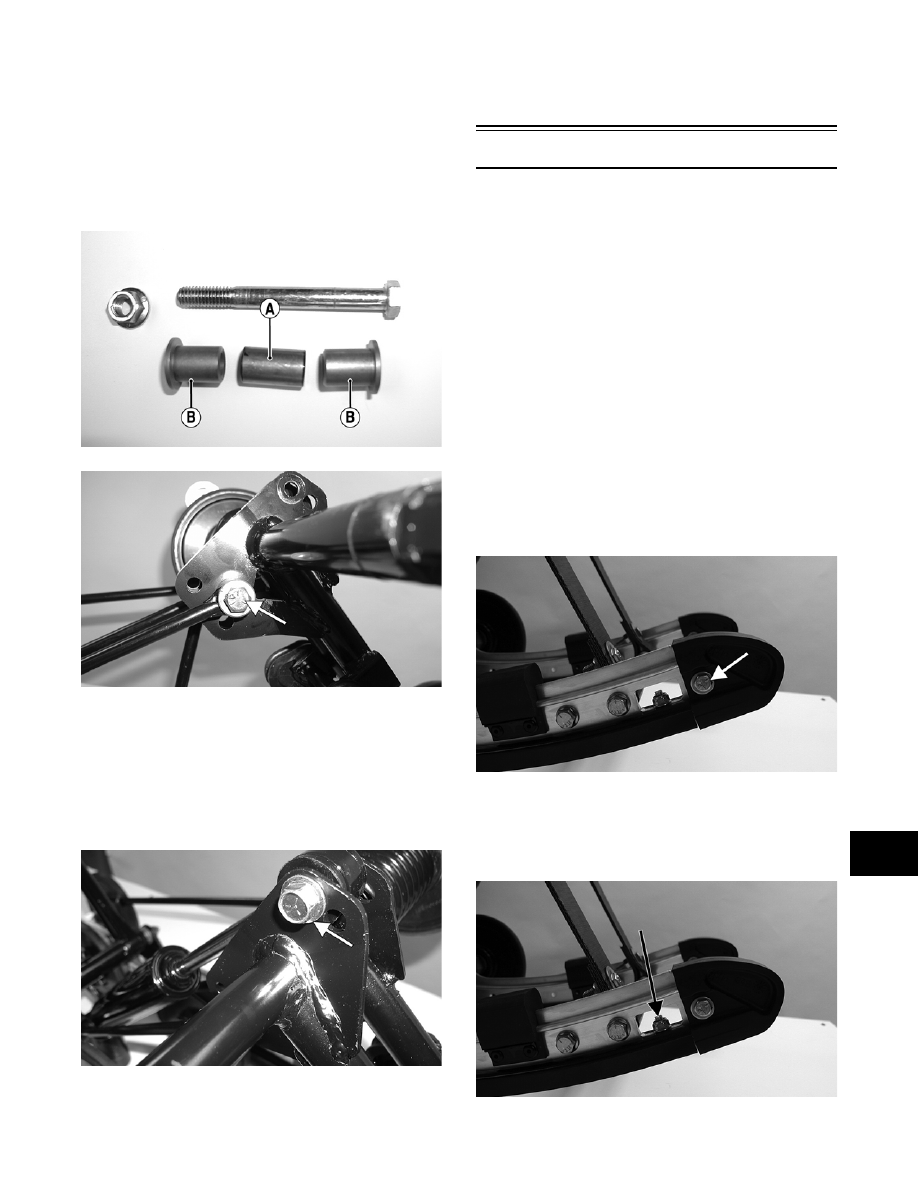

3. Position the shock links in the appropriate holes

of the idler arm brackets (see Chassis and Skid

Frame Mounting Locations in this section).

Place a spacer (A) between the center of the

brackets. Insert the axle links (B) into the upper

shock link eyelets; then insert the cap screw

with washer through the eyelets. Secure with a

cap screw, washer, and lock nut. Tighten

securely.

MS031A

MS048A

4. Install the upper shock absorber eyelet to the

appropriate hole in the idler arm as noted in dis-

assembling.

NOTE: Do not over-tighten the shock absorber

cap screw as the shock eyelet must be free to

pivot.

MS024A

5. Install the skid frame (see Installing Skid Frame

in this sub-section).

NOTE: It is advisable to install the rear arm

springs onto the adjuster blocks after the skid

frame has been installed.

Slide Rails

NOTE: The skid frame must be removed for this

procedure (see Removing Skid Frame in this sub-

section).

REMOVING

NOTE: When it is necessary to replace one or

both slide rails, it is recommended that one slide

rail be removed at a time. The remaining slide rail

will then hold the rail supports, axles, and brackets

in their correct assembly order. Always mark the

mounting hole locations during disassembly to

speed up the assembly process and to prevent any

damage. This method is much quicker than to

completely disassemble the entire skid frame. To

replace either rail, use the following procedure.

1. Remove the end cap from the slide rail. Account

for a cap screw, lock nut, and two flat washers.

MS016A

2. Remove the machine screw and lock nut secur-

ing the wear strip to the front of the slide rail;

then using a suitable driving tool, drive the wear

strip rearward off the slide rail.

MS016B