Snowmobile Arctic Cat (2007 year). Manual - part 17

2-53

2

2. Piston pin bore must be within specifications.

ATV-1069

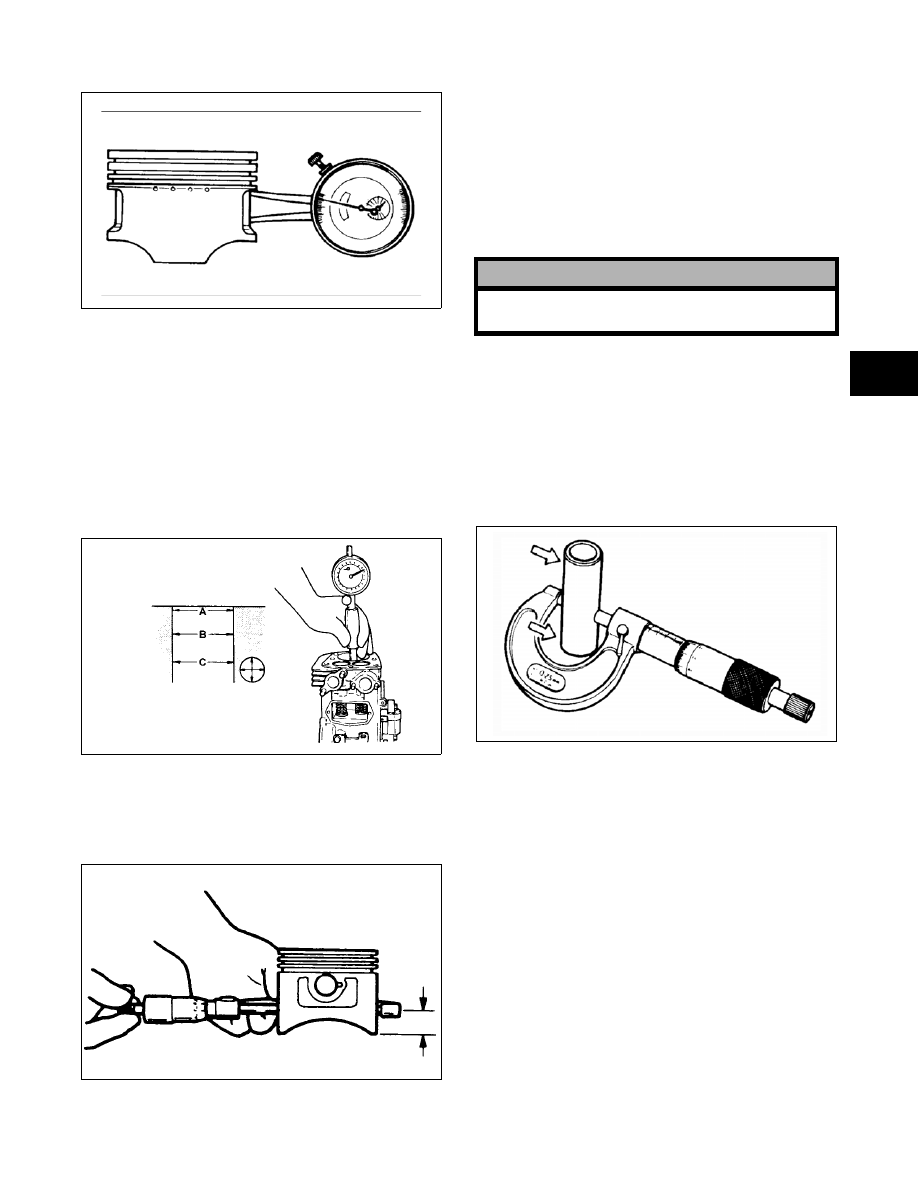

Measuring Piston Skirt/

Cylinder Clearance

1. Measure the cylinder front to back in six places

using a cylinder bore gauge. The amount of

wear is the difference between the largest and

smallest readings. If the determined wear

exceeds the limit indicated, bore to the next

oversize by using a boring machine or replace

the cylinder.

GEN-0032

2. Measure the corresponding piston diameter at a

point 14 mm (0.551 in.) above the piston skirt at

a right angle to the piston-pin bore. Piston diam-

eter must be within specifications.

GEN-0033

3. Piston skirt to cylinder clearance must be within

specifications.

4. If the piston/cylinder clearance exceeds the

limit, bore the cylinder and use an oversized pis-

ton or replace both cylinder and piston.

Installing Piston Rings

Install the rings in the appropriate grooves. Stagger

the gaps of the rings.

Measuring Piston Pin Diameter

1. Measure the piston pin diameter at each end and

in the center. If measurement is less than mini-

mum specifications, the piston pin must be

replaced.

2. Piston pin diameter must be within specifica-

tions.

ATV-1070

CYLINDER/CYLINDER HEAD

NOTE: If the cylinder/cylinder head assembly

cannot be trued, they must be replaced.

Cleaning/Inspecting Cylinder Head

1. Using a non-metallic carbon removal tool,

remove any carbon buildup from the combus-

tion chamber being careful not to nick, scrape,

or damage the combustion chamber or the seal-

ing surface.

2. Inspect the spark plug hole for any damaged

threads. Repair damaged threads using a “heli-

coil” insert.

! CAUTION

Incorrect installation of the piston rings will result in

engine damage.