Snowmobile Arctic Cat (2004 year). Manual - part 23

2-79

2

AN118

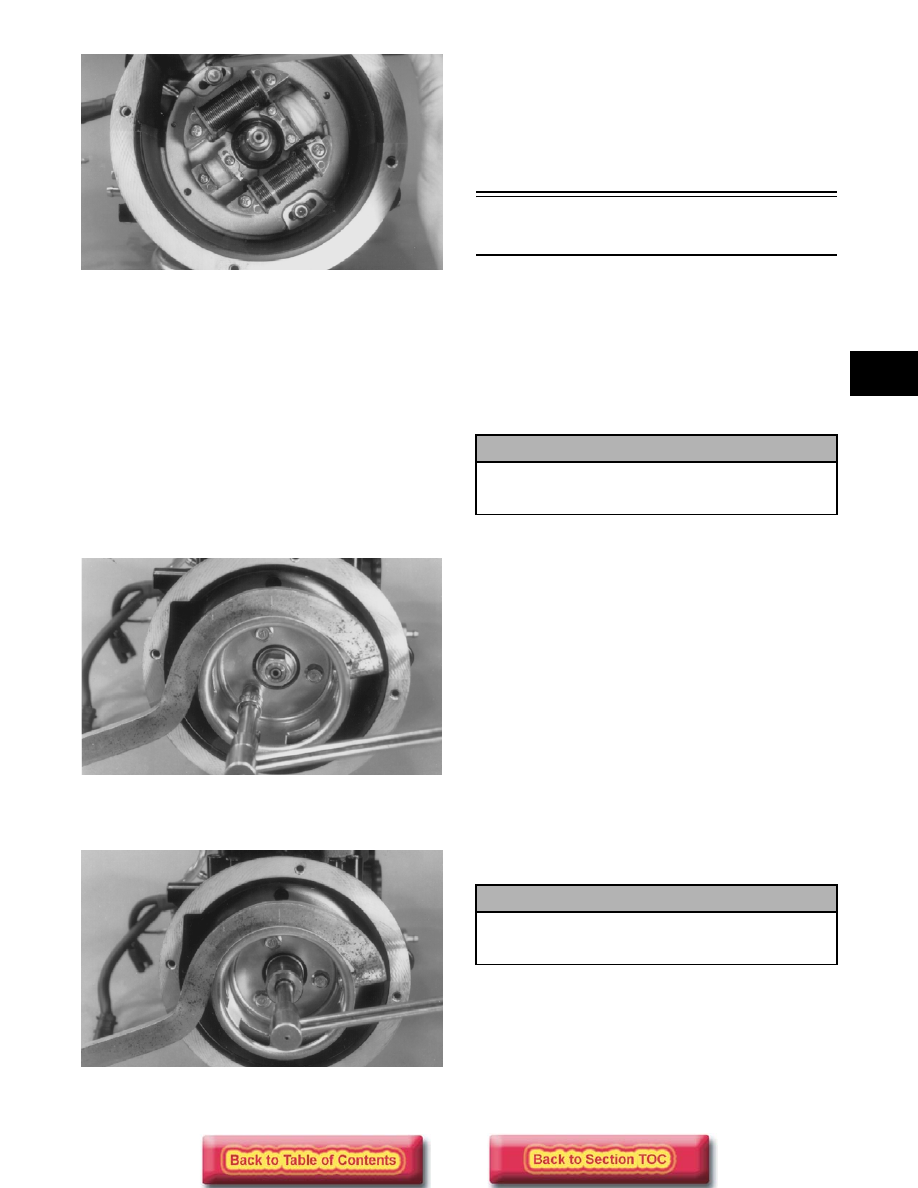

NOTE: Before installing the flywheel, be sure to

wipe the crankshaft and flywheel tapers clean

using a clean towel.

43. Install the key in the crankshaft and slide the

flywheel onto the crankshaft making sure the

keyways match; then finger-tighten the flywheel

nut with large flat washer and lock washer. Apply

red Loctite #271 to the threads of the flywheel nut.

44. Install the starter pulley; then secure the starter

pulley with three cap screws and lock washers.

Secure the pulley while using the spanner wrench

and tighten the three cap screws evenly to 0.7-

1 kg-m (5-7 ft-lb).

AN121

45. Using the spanner wrench, tighten the flywheel

nut to 7-9 kg-m (50.5-65 ft-lb).

AN122

46. Install the spark plugs and tighten to 2.5-2.8 kg-m

(18-20 ft-lb). Connect the spark plug caps.

47. Place the engine mounting brackets into position

on the crankcase and secure with the cap screws.

Tighten to 2.8-3.5 kg-m (20-25 ft-lb).

Assembling Engine

(570 cc Models)

NOTE: The use of new gaskets and seals is rec-

ommended when assembling the engine.

NOTE: When the use of a lubricant is indicated,

use Arctic Cat 50:1 Injection Oil.

1. Place the upper crankcase half (with its bottom

side up) on two blocks of wood.

2. Lightly grease the inner lips of the crankshaft

seals; then slide them onto the crankshaft.

3. Apply oil to the crankshaft bearings; then install

the crankshaft into the upper crankcase half. Be

sure the alignment hole in each bearing is

positioned over its respective dowel pin in the

crankcase; then seat the crankshaft.

NOTE: To check the bearing for proper position,

place the point of a sharp tool into the dimple

found in the bearing race. Strike the tool with the

palm of the hand in either direction. If the bearing

moves, it isn’t positioned correctly and must be

rotated until it drops onto the dowel pin.

NOTE: Make sure the crankshaft center C-ring

(integral with the center seal) is properly posi-

tioned in the groove of the upper crankcase half.

4. Install the four crankcase dowel pins.

5. Evenly apply a thin coat of Three Bond Sealant (p/n

0636-070) to the entire bottom half crankcase

sealing surface.

NOTE: Use only Three Bond Sealant (p/n 0636-

070) to seal the crankcase halves.

! CAUTION

To prevent damage to the crankshaft, crankshaft

bearings, or seals, make sure to always lift the

crankshaft from both ends.

! CAUTION

If the bearings are not properly seated during

assembly, the crankcase halves will not seal

tightly and severe engine damage will result.