Snowmobile Yamaha Phazer PZ50W, PZ50GTW, PZ50FXW, PZ50MW, PZ50VTW, PZ50MPW. Manual - part 57

5-65

ENG

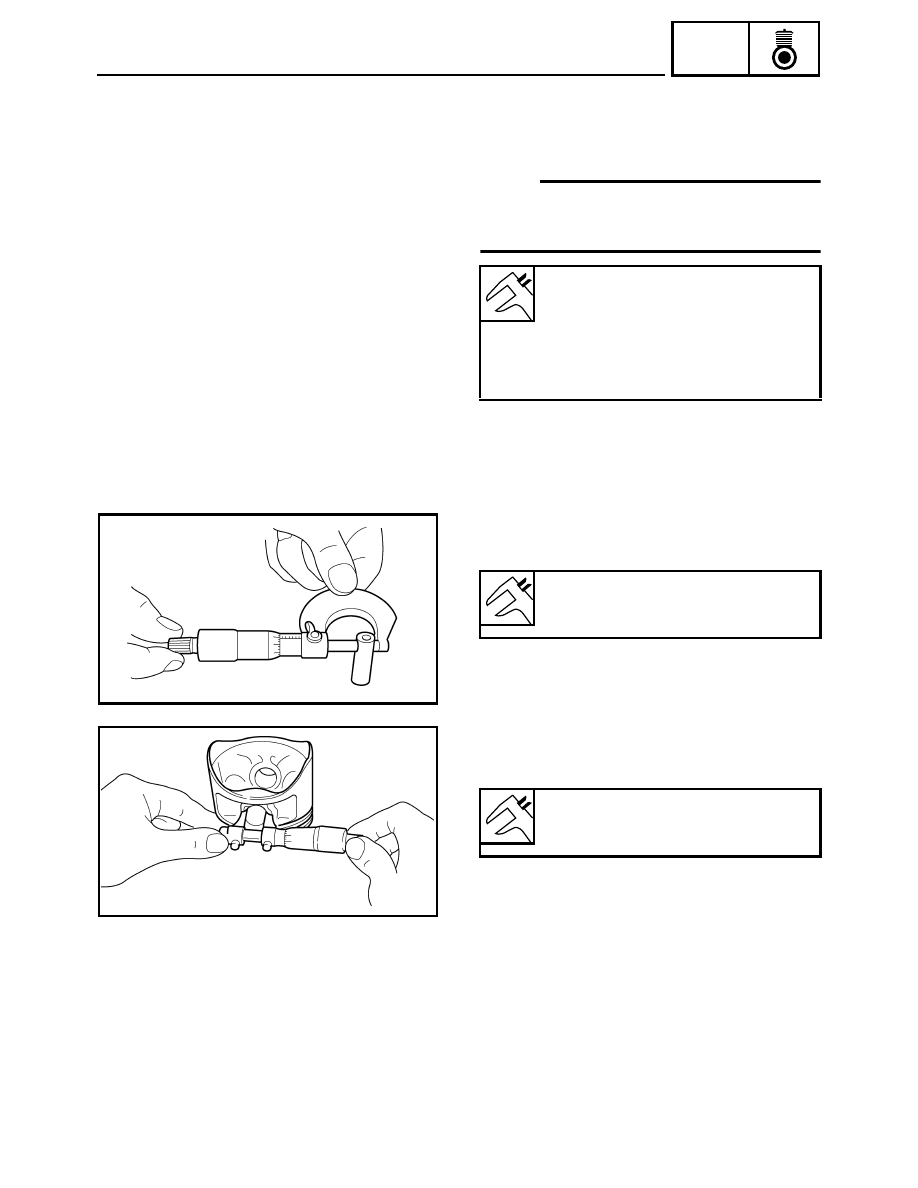

5. Measure:

• Piston ring end gap

Out of specification

→ Replace the piston

rings as a set.

NOTE:

The oil ring expander spacer’s end gap cannot be

measured. If the oil ring rail’s gap is excessive,

replace all three piston rings.

6. Inspect:

• Piston pin

Blue discoloration/grooves

→ Replace the

piston pin and then check the lubrication sys-

tem.

7. Measure:

• Piston pin outside diameter

Out of specification

→ Replace the piston pin.

Piston ring end gap:

Top ring:

0.15 ~ 0.25 mm (0.006 ~ 0.010 in)

2nd ring:

0.30 ~ 0.45 mm (0.012 ~ 0.018 in)

Oil ring:

0.10 ~ 0.40 mm (0.004 ~ 0.016 in)

Piston pin outside diameter:

16.991 ~ 17.000 mm

(0.6689 ~ 0.6693 in)

8. Measure:

• Piston pin bore inside diameter

Out of specification

→ Replace the piston.

Piston pin bore inside diameter:

17.002 ~ 17.013 mm

(0.6694 ~ 0.6698 in)