Index Snowmobiles / ATV Snowmobile Yamaha Phazer PZ50W, PZ50GTW, PZ50FXW, PZ50MW, PZ50VTW, PZ50MPW - service manual 2007 year

|

|

|

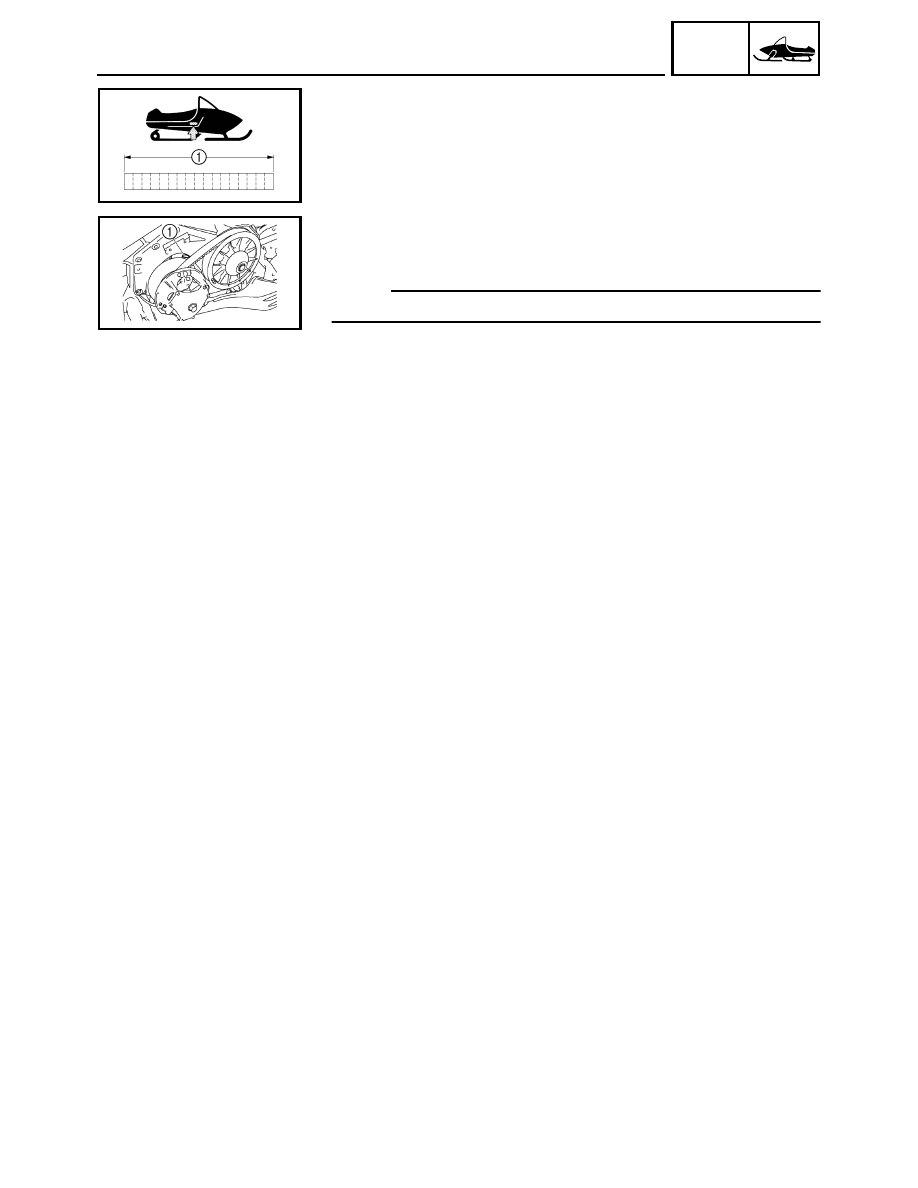

1-1 GEN INFO GENERAL INFORMATION MACHINE IDENTIFICATION FRAME SERIAL NUMBER The frame serial number 1 is located on the right-hand side of the frame ENGINE SERIAL NUMBER The engine serial number 1 is located on the left-hand side of the crank- NOTE: Designs and specifications are subject to change without notice. |