Snowmobile Polaris IQ (2007-2008 year). Manual - part 16

3.4

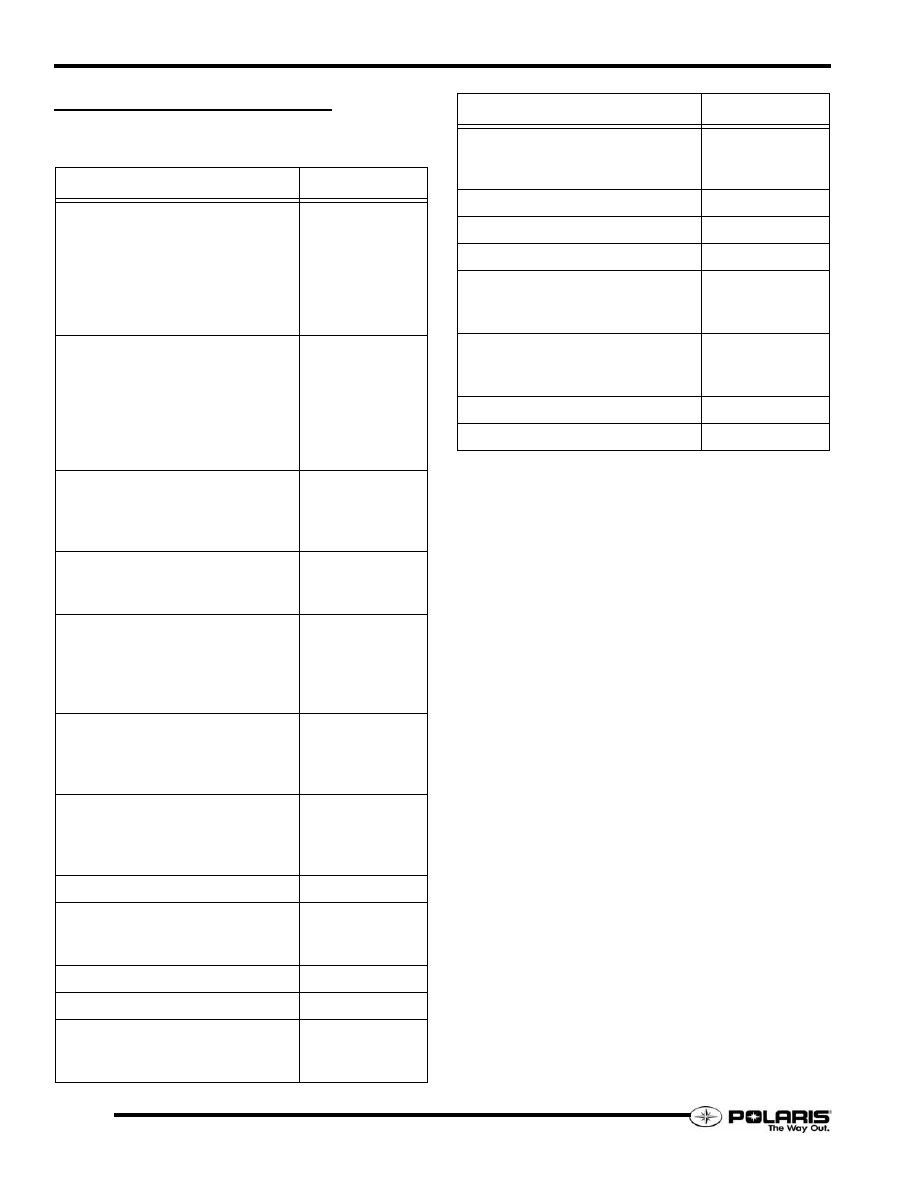

Maintenance

MAINTENANCE PRODUCTS

Engine Oils / Lubricants / Misc.

D

ESCRIPTION

P

ART

N

UMBER

Premium 2-Cycle Oil

Quart

Gallon

2.5 Gallon

16 Gallon

55 Gallon

330 Gallon

2875035

2875036

2874037

2875038

2875039

2875040

VES Gold 2-Cycle Oil

Quart

Gallon

2.5 Gallon

16 Gallon

55 Gallon

330 Gallon

2874438

2874439

2874443

2874440

2874441

2874442

Racing 2-Cycle Oil

Quart

Gallon

16 Gallon

2873025

2873023

2873919

PS-4 4-Cycle 0W-50 Oil

Quart

55 Gallon

2874865

2874867

PS-4 4-Cycle 2W-50 Oil

Quart

Gallon

16 Gallon

55 Gallon

2876244

2876245

2876247

2876246

Synthetic Chaincase Lubricant

Quart

Gallon

2.5 Gallon

2873105

2873106

2872952

Antifreeze 60/40 Premix

Quart

Gallon

55 Gallon

2871534

2871323

2872278

Shock Oil - 5W - Walker Evans

2874522

Shock Oil - Fox

Quart

Gallon

2870995

2872279

Shock Oil - Ryde FX / Arvin

2873716

Brake Fluid - DOT 4

2872189

Fogging Oil

Aerosol

Quart

2870791

2871517

Premium All Season Grease

3oz. Grease Gun Kit

14oz.

2871312

2871423

Starter Grease

2871460

Carbon Clean Plus

2871326

Isopropyl

2870505

Fuel Stabilizer

Quart

2.5 Gallon

2870652

2872280

Cross Shaft Assembly Lubricant

8oz.

2.5 Gallon

2872435

2872436

Three Bond Sealant 5oz.

2871557

Loctite 242

2871950

D

ESCRIPTION

P

ART

N

UMBER