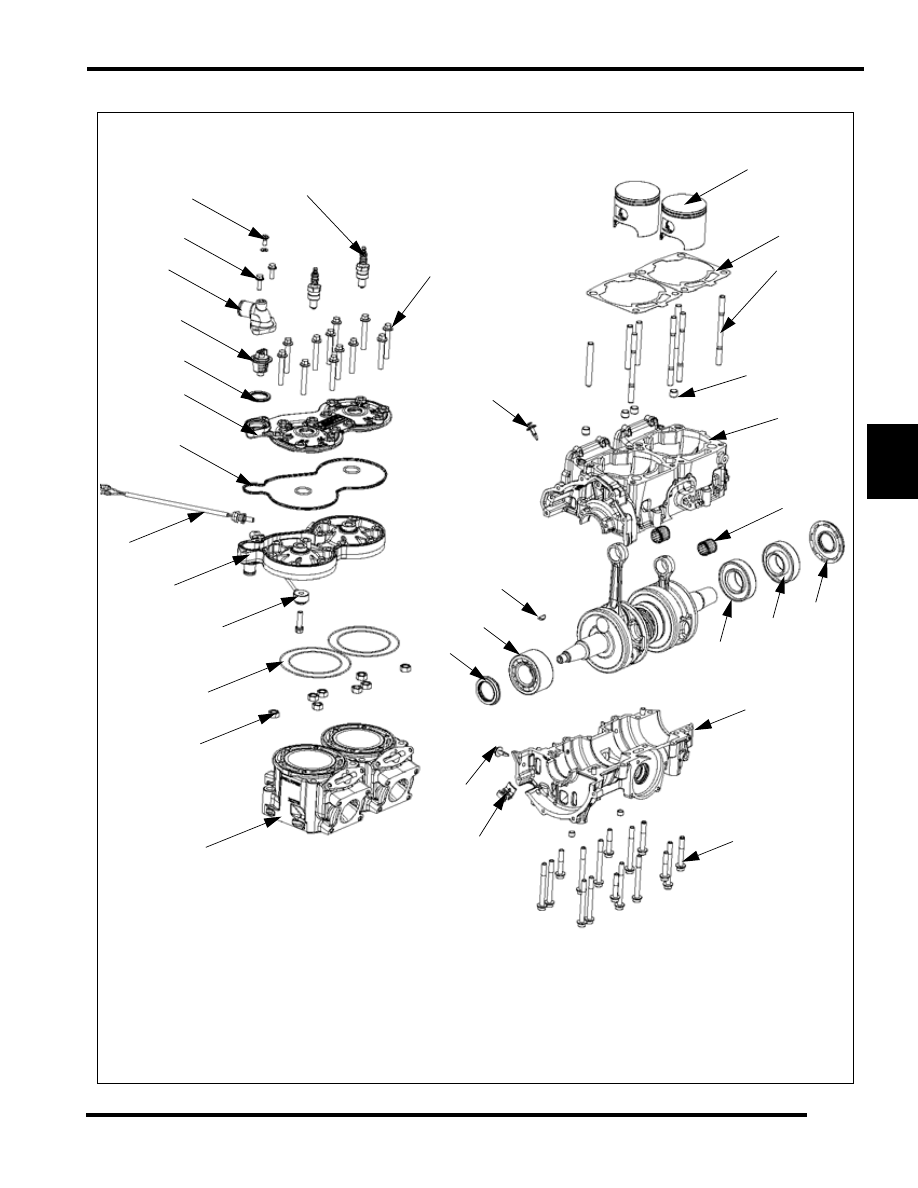

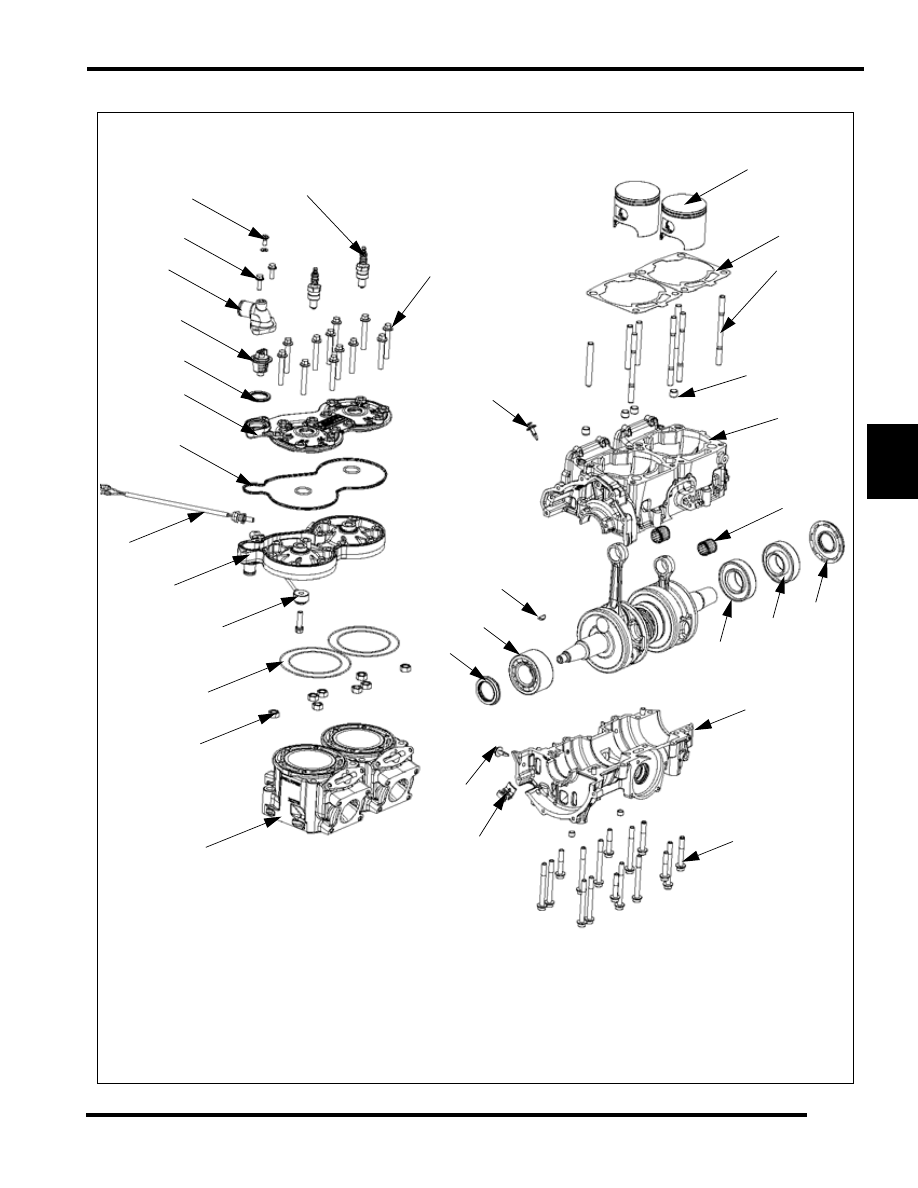

Snowmobile Polaris Two Stroke (2007 year). Manual - part 35

5.33

ENGINE

5

600/700 CFI Engine Disassembly

1

2

5

3

6

7

9

10

11

12

13

14

15

16

18

19

20

21

24

27

28

26

31

32

29

25

23

17

4

8

22

30

If new see

installation

height on

page 5.5

|

|

|

5.33 ENGINE 5 600/700 CFI Engine Disassembly 1 2 5 3 6 7 9 10 11 12 13 14 15 16 18 19 20 21 24 27 28 26 31 32 29 25 23 17 4 8 22 30 If new see installation height on page 5.5 |