Snowmobile Polaris Two Stroke (2007 year). Manual - part 30

5.13

ENGINE

5

1.

Disconnect the coil pack and CDI from the wiring harness.

2.

Loosen the carburetor clamps (1) and remove the

carburetors from the mounting boots.

3.

Note where the oil lines are routed and remove the oil lines

from the carburetors.

4.

Remove the carburetor mounting boots (2) from the

cylinders.

5.

Remove both the cylinder head (3) and the exhaust side fan

(4) shrouds from the engine assembly.

• 340 has a intake side shroud

6.

After removing the fan shrouds, take note of the vibration

dampener (5) located between the cylinders intake side

(550 only).

7.

Remove the recoil cover (6).

8.

Remove the recoil cup (7).

9.

Hold the flywheel with the holding wrench PN 8700229

and remove the flywheel nut and washer.

10. Using a flywheel puller (PN 2871043), remove the

flywheel (8) from the engine. Do not install the puller bolts

in amy more than 5/16” of an inch/7.9mm into the flywheel

threads or stator damage may result.

11. Remove the flywheel.

12. Remove the blower housing that the stator is mounted too.

NOTE: Make sure to account for the dowels on the

blower housing (550 only).

13. Remove the oil pump (9). Note the o-ring and shim

placement.

14. Remove the cylinder head bolts (10).

15. Remove the cylinder head (11).

16. Remove the head gasket (12). During the removal process

note that the gasket has a EX for exhaust side and UP for

the orientation.

17. Remove the cylinder base nuts (13) and carefully remove

each cylinder (550 only)

18. Remove the reed valve assembly (14) from the crankcase

(550 only).

19. Remove the wrist pin c-clips

20. Using a piston pin puller (PN 2870386) remove the wrist

pins from the pistons.

21. Turn the crankcase over and remove the crankcase bolts

(15).

22. Carefully turn the case back over and separate the case

halves.

23. Remove the crankshaft and crankcase seals (16).

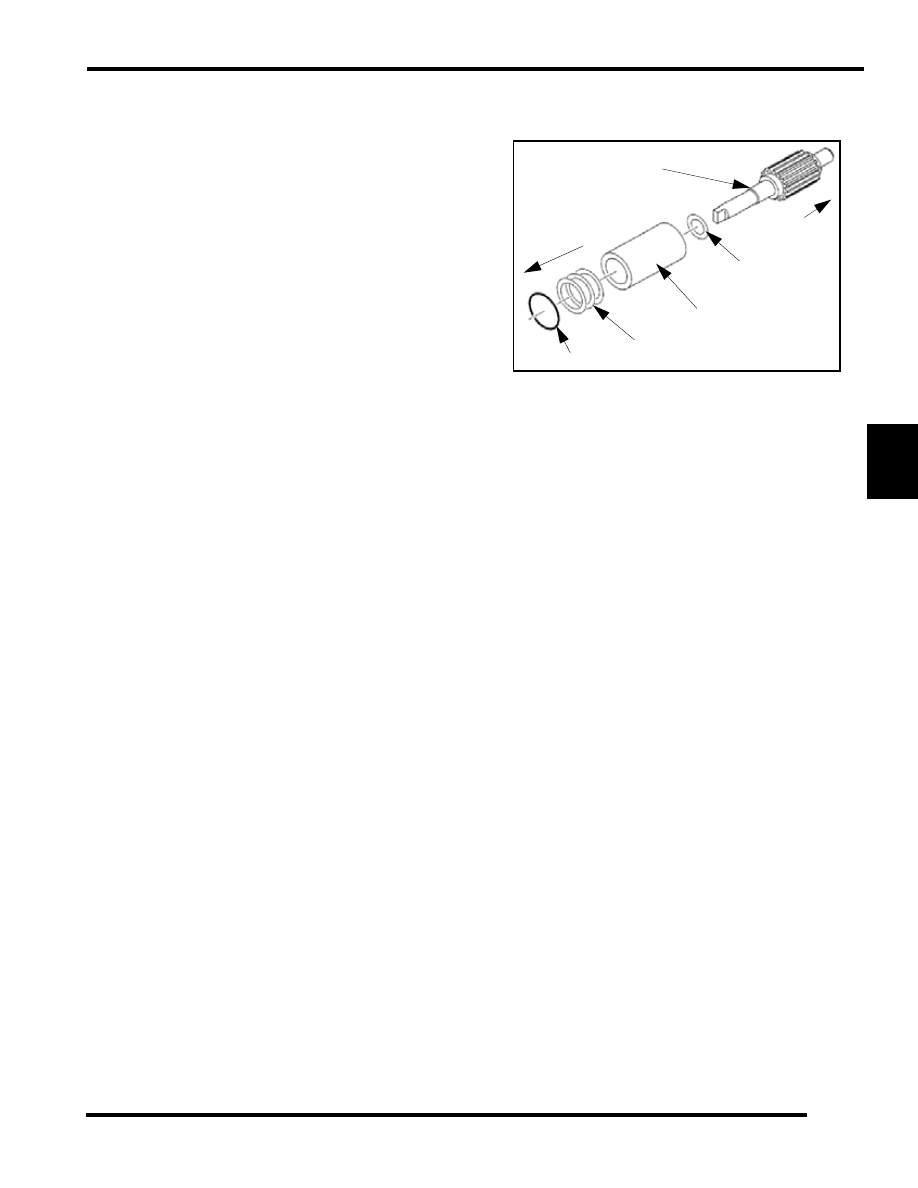

24. Remove the oil pump bushing, spacer, and cross shaft (17)

and inspect for any wear or damage.

Engine Assembly

1.

Insert the oil pump cross shaft, spacer and bushing.

2.

Install a new o-ring on the oil pump.

3.

Place the oil pump aside for later installation.

4.

Set the crankshaft into the lower case half.

5.

Grease the oil pump drive gear area.

NOTE:

Make sure that the crankshaft rotates

smoothly and does not bind. Rotate the bearings so

that the anti-rotation pins are resting in their

appropriate galleries.

6.

Apply 3-Bond (PN 2871557) sealer to the top half of the

crankcase.

7.

Install new crankcase oil seals with spring and lip facing

inward toward the crank bearing.

8.

Match up the top half of the crankcase to the lower case and

hold the case halves together and turn it upside down.

Gear

Spacer

Bushing

Spacers

o-ring

Engine side

Oil Pump Side