Snowmobile Polaris 600 IQ Touring (2010 year). Manual - part 26

105

MAINTENANCE

Clutch System

n

Drive Belt Condition

Periodically check the condition and tension of the drive belt, and

always carry a spare. Inspect the belt for signs of excessive wear: frayed

edges, missing cogs, cracks and excessive looseness. Replace the belt if

any of these conditions exist. See Drive Belt Troubleshooting on page

123.

For improved drive-away during extremely cold temperatures, remove

the belt and warm it to room temperature. Reinstall it before starting the

snowmobile.

n

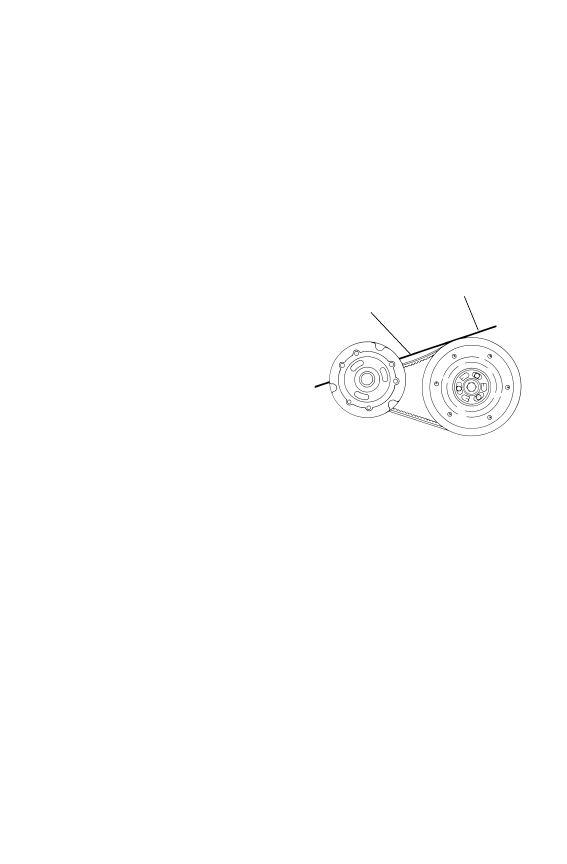

Drive Belt Deflection

Measure belt deflection with both

clutches at rest and in their full

neutral position.

Place a straight edge on the belt

and apply downward pressure

while measuring at point A. This

measurement should be 1 1/4"

(3.2 cm).

Drive Belt Adjustment

1. Install the L-wrench into the open threaded hole in the outer sheave

of the clutch (see page 106). Turn the wrench clockwise slightly to

remove pressure from the sheaves.

2. Loosen the 7/16" jam nut on the belt width adjuster.

3. Using a 1/8" Allen wrench, adjust the threaded set screw as needed.

Tip: Turn the set screw in (clockwise) to increase the distance between the

sheaves and out (counterclockwise) to decrease the distance.

4. Tighten the jam nut.

Straight

Edge

Measure

A