Challenger Terra Gator 3244 Chassis. Manual - part 126

627333-A

8-11

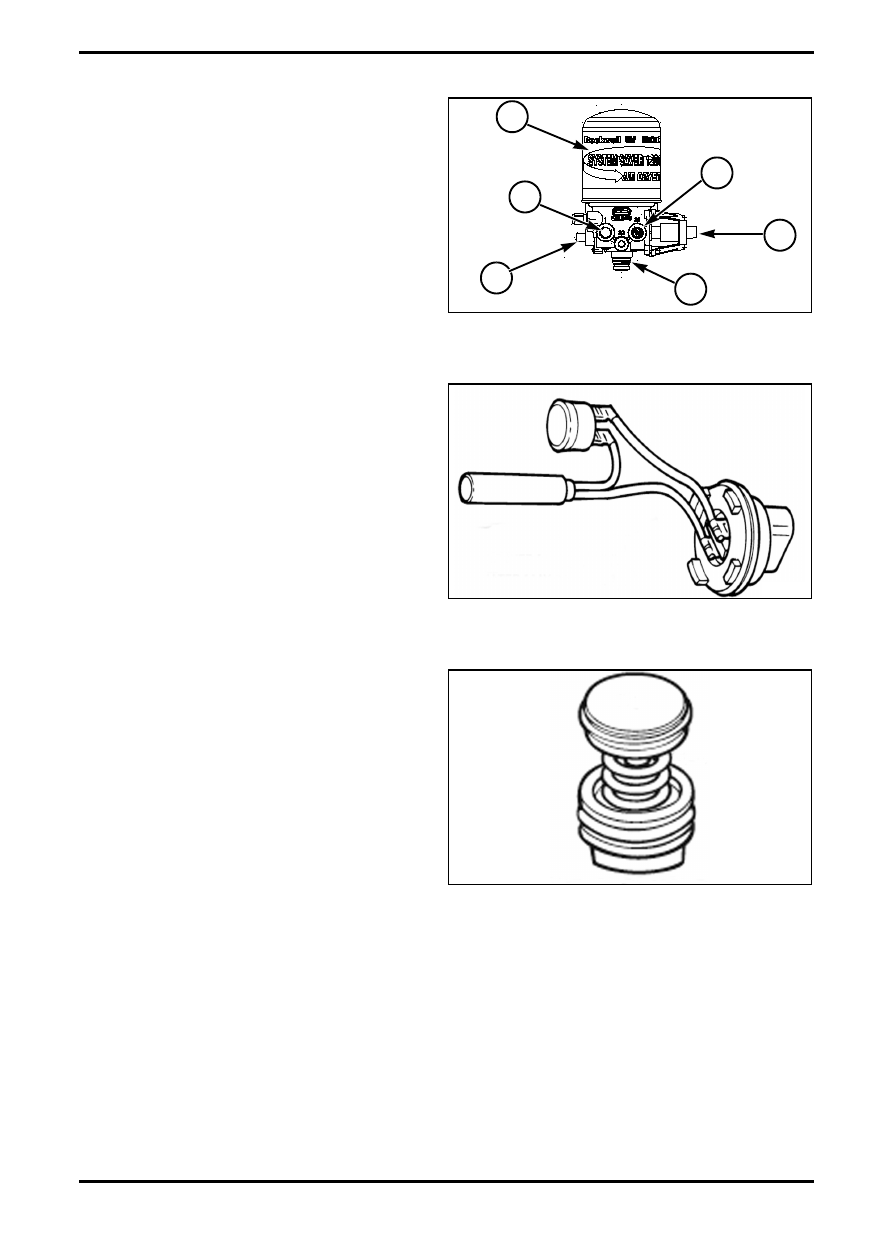

Air Dryer

AIR DRYER COMPONENTS

FIG. 5: Air dryer assembly.

(1)

Heater

(2)

Turbo Cut-off Valve

(3)

Desiccant Cartridge

(4)

Outlet Check Valve

(5)

Regeneration Valve

(6)

Purge Valve

Heater

FIG. 6: Heater is located in air dryer base. Heater

prevents water that collects in air dryer from freezing.

The heater consists of a cylindrical resistive-type

heating element and small circular thermostat. Heater

is 12-volt.

To replace heater, disconnect electrical plug. Remove

screws, receptacle and O-ring from base to access

retainer screw. Remove entire screw and remove entire

heater assembly. Install new element and thermostat in

cavities. Install new retainer and screw to hold element

and thermostat in place. Install new O-ring and

receptacle and fasten in place with screws.

Turbo Cut-off Valve

FIG. 7: Turbo cut-off valve is located in inlet port of air

dryer. The turbo cut-off valve closes path between air

compressor and air dryer purge valve during

compressor unload. This prevents a loss of

turbocharger boost pressure during a compressor

unload cycle, keeping boost pressure for maximum

engine horsepower.

IMPORTANT: There is no spring in the turbo cut-off

valve assemblies used on U Series air dryers.

To replace turbo cut-off valve, remove snap ring. Cover

and spring may fall out of bore. Remove desiccant

cartridge. Use a wooden stick to push piston spring and

cover out if they don’t fall out. Clean and inspect the

valve bore. If bore is damaged so that a tight seal

cannot be maintained, replace air dryer.

Install new lip seal on piston. Seal lip must face up

toward top of piston. Install new O-ring on cover. Use

grease supplied with kit to apply thin film to valve bore

and O-ring. Install new piston with flat side toward

dryer. Install new spring, cover, and snap ring to hold

components in place. Install plug. Replace desiccant

cartridge.

FIG. 5

M6205002

1

4

6

5

2

3

FIG. 6

M6215001

FIG. 7

M6215002