Challenger Terra Gator 3244 Chassis. Manual - part 14

627333-A

1-53

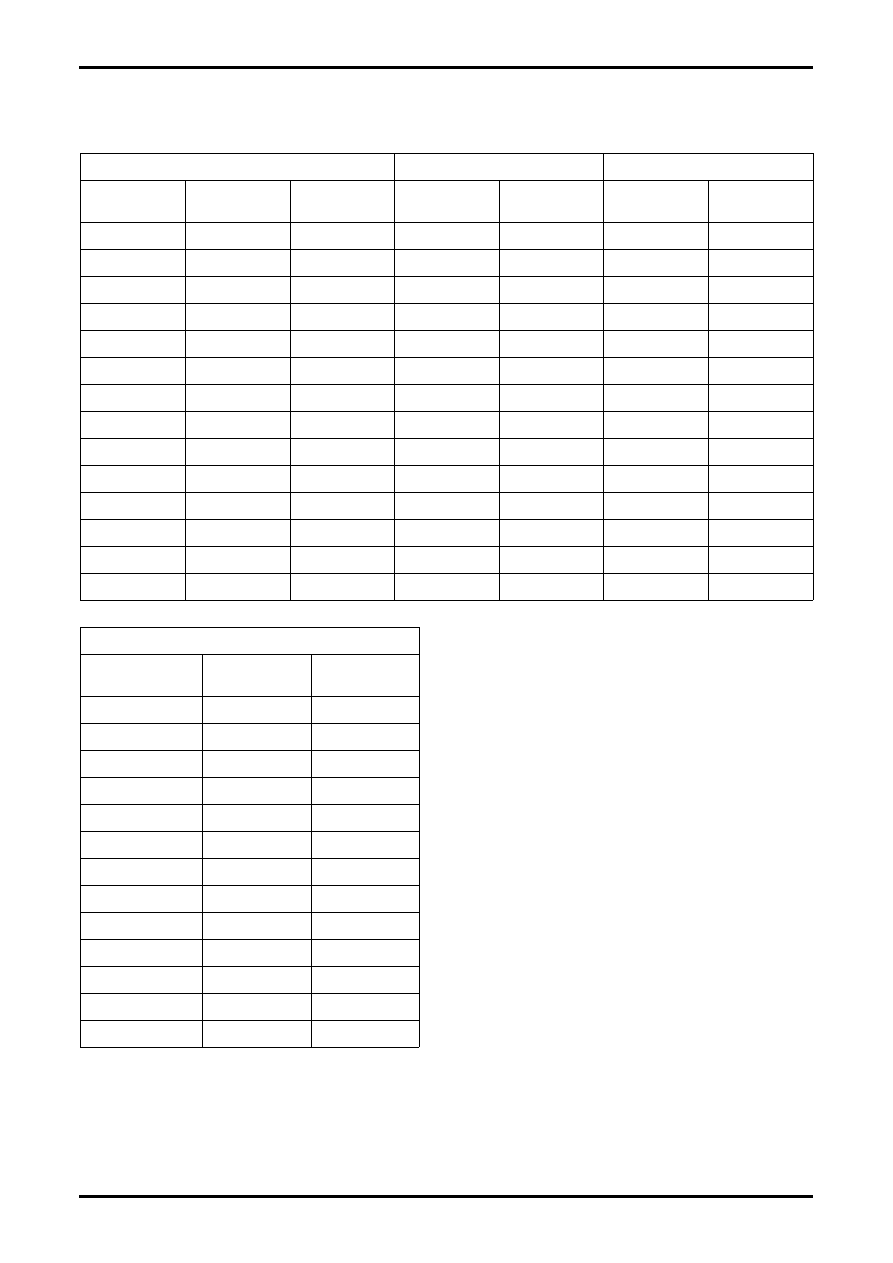

Torque Specifications

SAE Fasteners

Assembly Torque for SAE Fasteners

Standard

High

Low

Thread Size

Torque

lbf ft

Torque

Nm

Torque

lbf ft

Torque

Nm

Torque

lbf ft

Torque

Nm

1/4 - 20

9 ± 1

12 ± 3

10 ± 1

13 ± 3

4 ±0.5

6 ± 1

5/16 - 18

18 ± 2

25 ± 6

20 ± 2

28 ± 7

10 ± 1

13 ± 3

3/8 - 16

35 ± 4

47 ± 9

40 ± 4

50 ± 10

18 ± 2

25 ± 6

7/16 - 14

50 ± 5

70 ±15

60 ± 6

80 ± 15

30 ± 3

40 ± 8

1/2 - 13

75 ± 8

105 ± 20

90 ± 9

120 ± 20

45 ± 5

60 ± 12

9/16 - 12

120 ± 10

160 ± 30

130 ± 13

175 ± 30

60 ± 5

85 ± 15

5/8 - 11

160 ± 15

215 ± 40

175 ± 15

240 ± 40

85 ± 10

115 ± 20

3/4 - 10

275 ± 30

370 ± 50

320 ± 30

430 ± 60

150 ± 15

200 ± 40

7/8 - 9

460 ± 50

620 ± 80

520 ± 50

700 ± 90

240 ± 25

325 ± 40

1 - 8

660 ± 70

900 ± 100

775 ± 75

1050 ± 150

370 ± 35

500 ± 65

1 1/8 - 7

960 ± 100

1300 ± 150

1070 ± 105

1450 ± 150

515 ± 50

700 ± 90

1 1/4 - 7

1320 ± 130

1800 ± 200

1550 ± 155

2100 ± 250

975 ± 95

1000 ± 125

1 3/8 - 6

1780 ± 180

2400 ± 300

1990 ± 200

2700 ± 300

1315 ± 130

1000 ± 150

1 1/2 - 5

2280 ± 230

3100 ± 350

2650 ± 265

3600 ± 400

1680 ± 165

1700 ± 200

Standard Taperlock Studs

Thread Size

Torque

lbf ft

Torque

Nm

1/4

6

8

5/16

13

17

3/8

26

35

7/16

33

45

1/2 48

65

5/8

80

110

3/4

125

170

7/8

190

260

1

300

400

1 1/8

390

525

1 1/4

550

750

1 3/8

700

950

1 1/2

880

1200