Yamaha XV1700P, XV1700PC. Service Manual - part 8

3 - 8

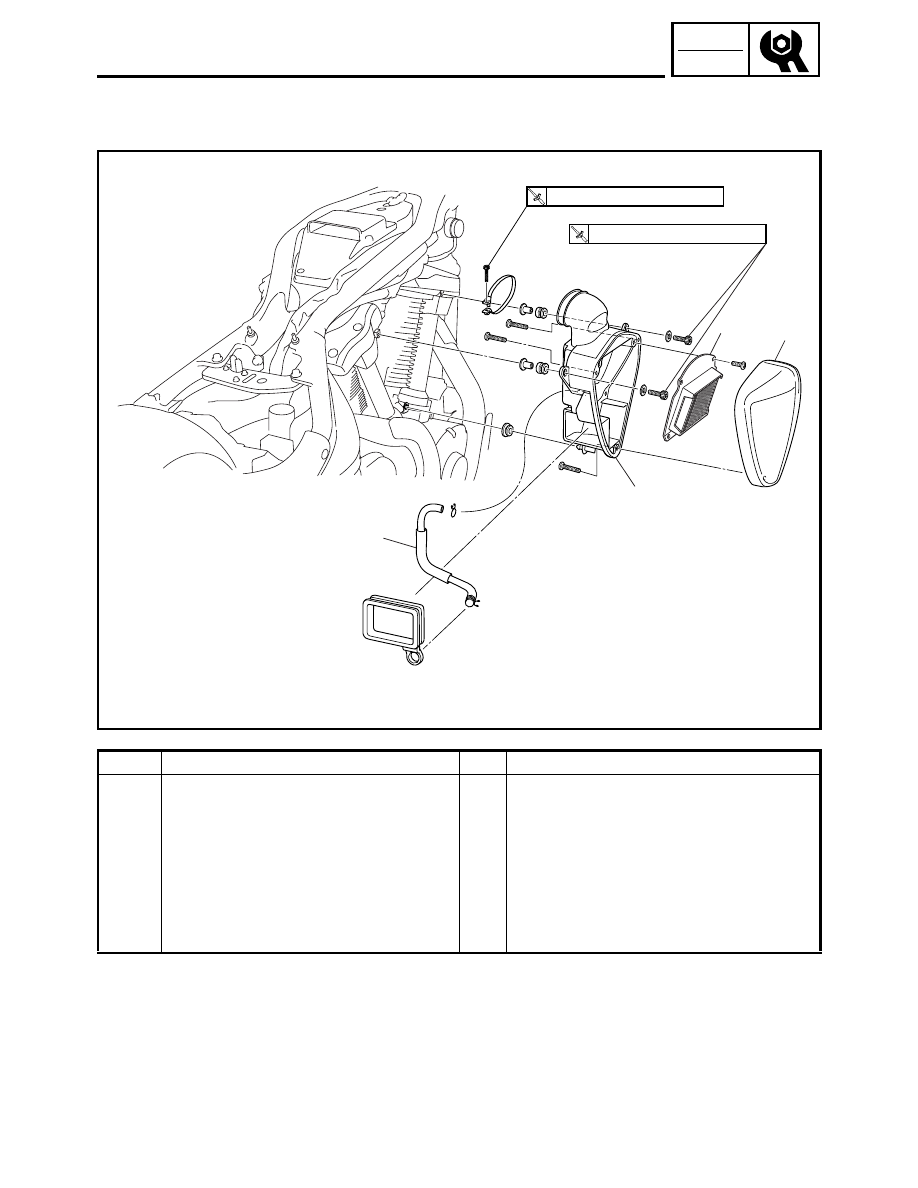

CHK

ADJ

AIR FILTER CASE

EAS00043

AIR FILTER CASE

4

1

3

2

(4)

T

R

.

.

7 Nm (0.7 m

•

kg, 5.1 ft

•

Ib)

T

R

.

.

3 Nm (0.3 m

•

kg, 2.2 ft

•

Ib)

Order

Job/Part

Q’ty

Remarks

Removing the air filter case

Remove the parts in the order listed.

Fuel tank

Refer to “FUEL TANK”.

1

Air filter case

1

2

Air filter case cover

1

3

Air filter element

1

4

Air filter check hose

1

For installation, reverse the removal

procedure.