Yamaha XVS1100 (L). Service Manual - part 21

7-28

Y

G

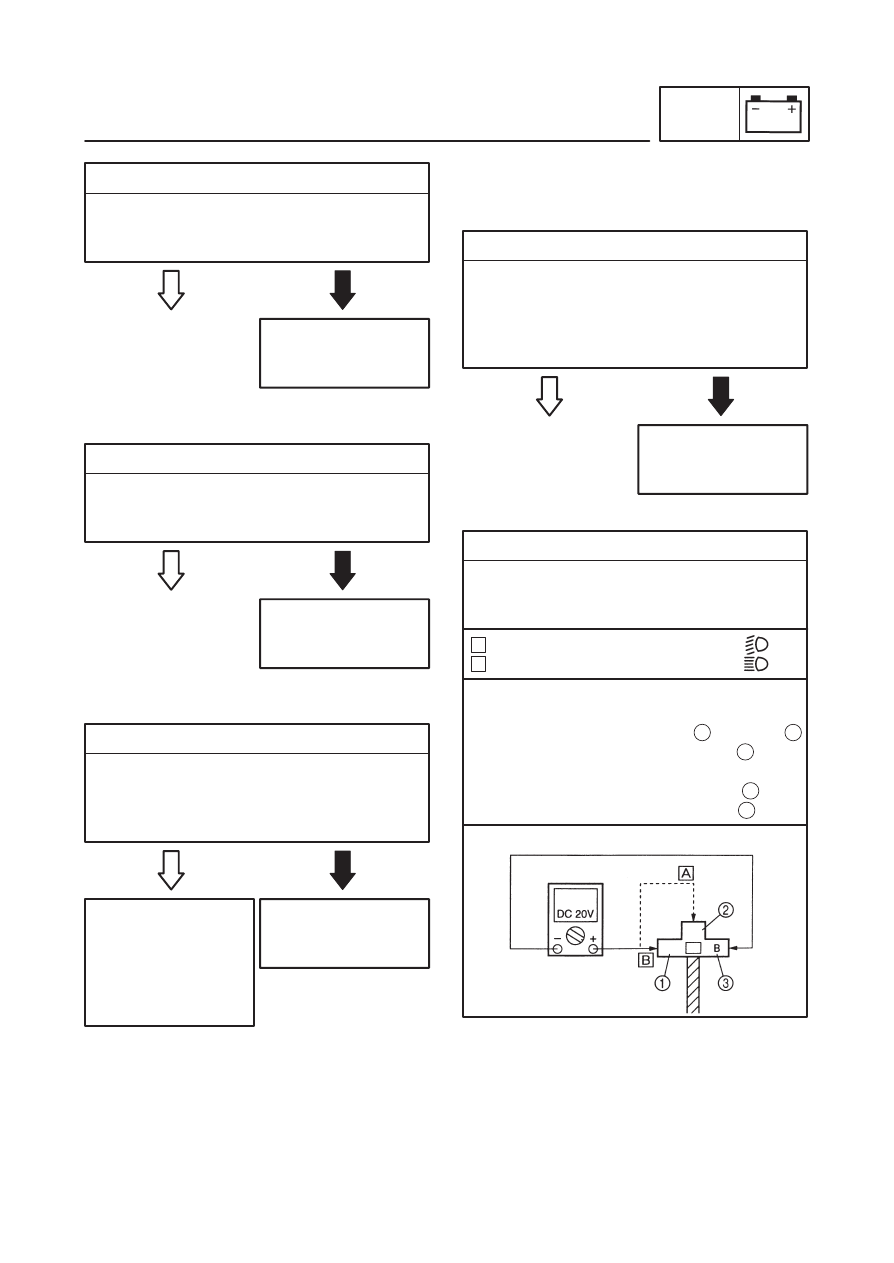

Check the dimmer switch for continuity.

Refer to “CHECKING THE SWITCHES”.

Is the dimmer switch OK?

YES

The dimmer switch is

faulty. Replace the

left handlebar switch.

NO

5. Dimmer switch

EAS00786

Check the pass switch for continuity.

Refer to “CHECKING THE SWITCHES”.

Is the pass switch OK?

YES

The pass switch is

faulty. Replace the

left hadlebar switch.

NO

6. Pass switch

EAS00787

Check the entire lighting system’s wiring.

Refer to “CIRCUIT DIAGRAM”.

Is the lighting system’s wiring properly con-

nected and without defects?

YES

Properly connect or

repair the lighting sys-

tem’s wiring.

NO

7. Wiring

Check the condition

of each of the lighting

system’s circuits.

Refer to “CHECKING

THE LIGHTING SYS-

TEM”.

Check the headlight bulb and socket for con-

tinuity.

Refer to “CHECKING THE BULBS AND

BULB SOCKETS”.

Are the headlight bulb and socket OK?

YES

Replace the head-

light bulb, socket or

both.

NO

1. Headlight bulb and socket

2. Voltage

Connect the pocket tester (DC 20 V) to the

headlight and high beam indicator light cou-

plers as shown.

When the dimmer switch is set to “

”

When the dimmer switch is set to “

”

A

B

Headlight coupler (wire harness side)

EAS00788

CHECKING THE LIGHTING SYSTEM

1. The headlight and the high beam indicator

light fail to came on.

Headlight

Tester positive probe

yellow

or green

Tester negative probe

black

High beam indicator light

Tester positive probe

yellow

Tester negative probe

brack

1

2

3

4

5

LIGHTING SYSTEM

ELEC

EAS00784