ATV Arctic Cat 2002. Service Manual - part 15

88

3

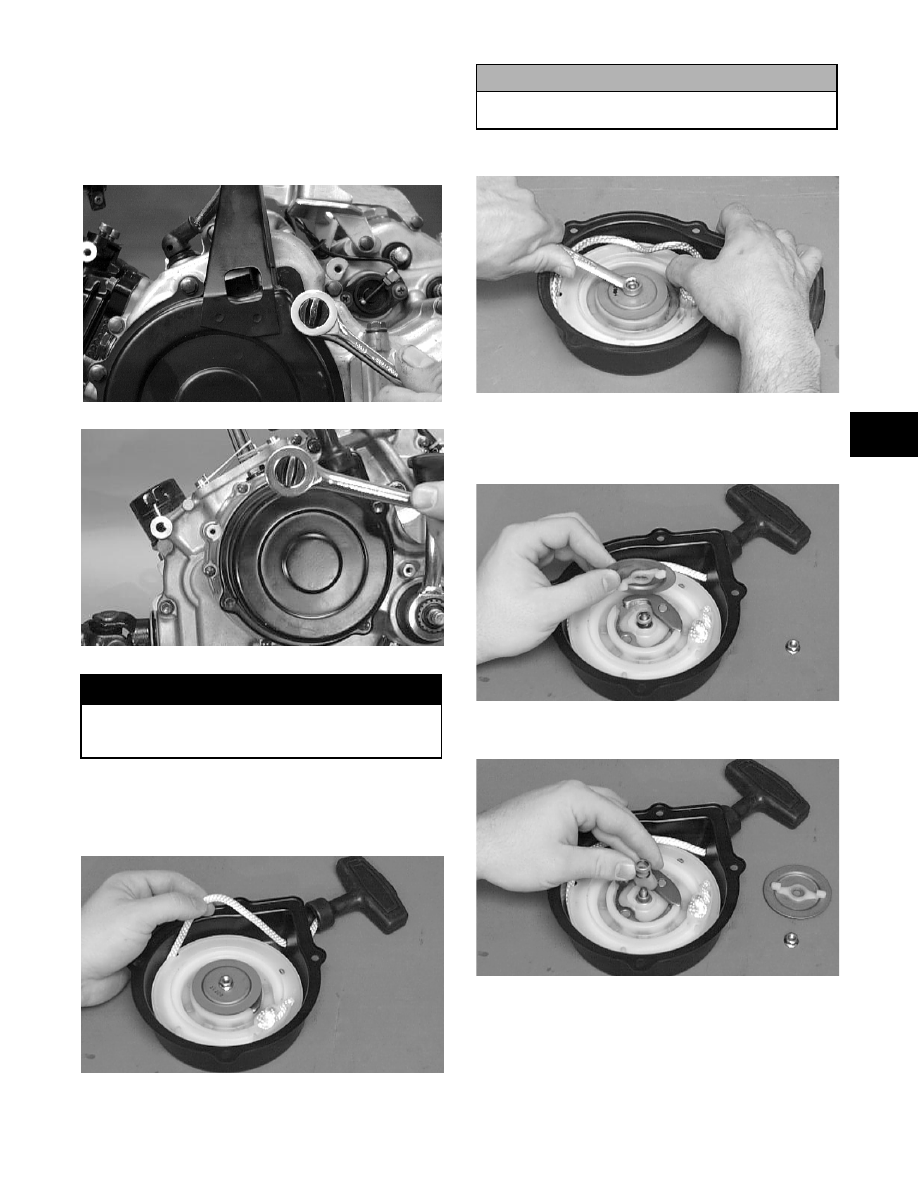

Removing/Disassembling

1. Remove the cap screws securing the recoil starter

assembly to the left-side cover; then remove the

starter noting (on the 250/300) the location of the

single washer closest to the center of the

crankcase. Account for a gasket.

4)

79)

2. Rotate the reel counterclockwise until the notch of

the reel is near the rope guide in the case. Guide

the rope into the notch and slowly allow the reel to

retract until all spiral spring tension is released.

>677)

3. Remove the nut.

>67)

4. Slowly release the friction plate and lift the plate

with ratchet guide free of the recoil housing; then

remove the ratchet guide from the friction plate.

>67)

5. Remove the spring, collar, and friction spring.

>67)

6. Remove the ratchet.

! WARNING

) & !

! A

&;&$

! CAUTION

) &!

! $

RepairPro Service Manual