ATV Arctic Cat 2002. Service Manual - part 12

9

3

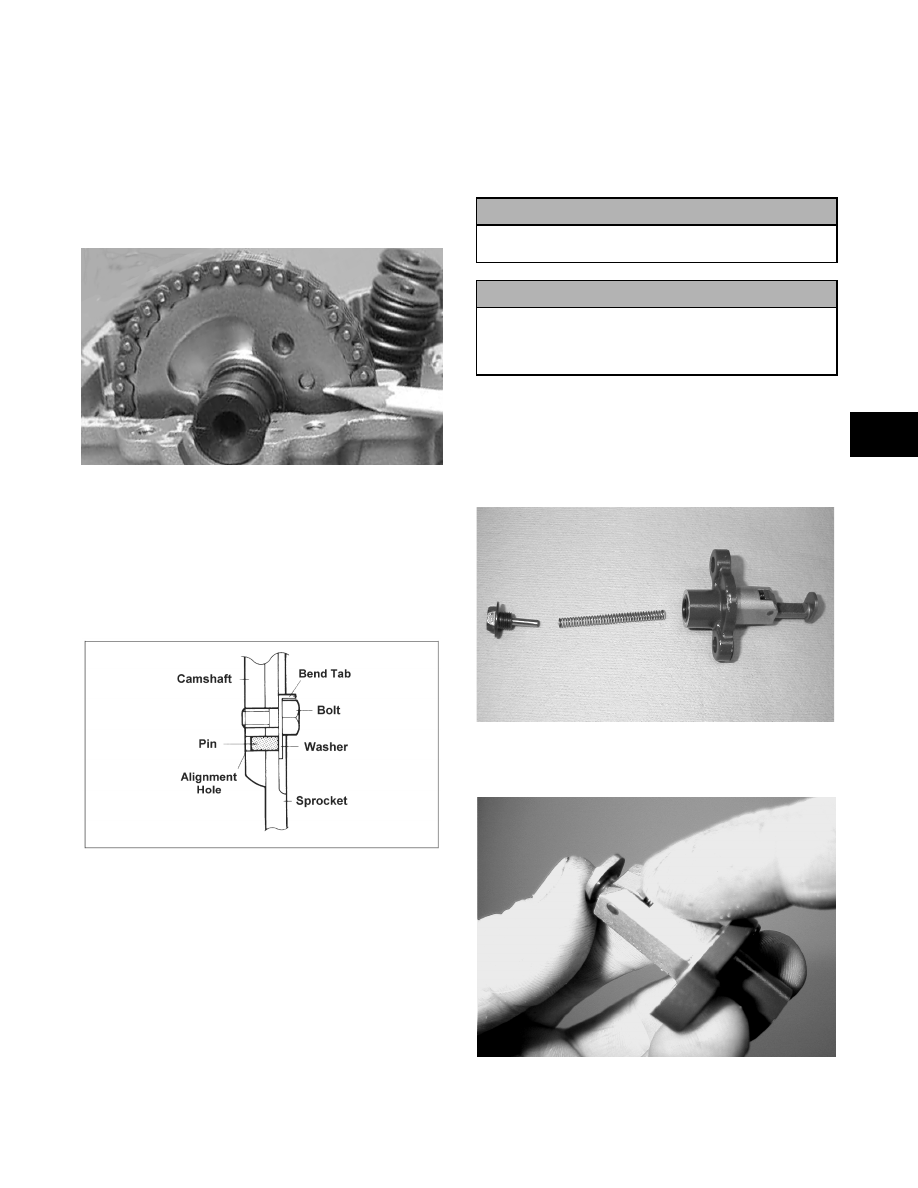

14. With the alignment pin installed in the camshaft

and the cam lobes directed down (toward the

piston), place the camshaft in position and verify

that the timing mark on the magneto is visible

through the inspection plug and that the timing

marks on the camshaft sprocket are parallel with

the valve cover mating surface.

B &

!

!$

-)6

15. Apply red Loctite #271 to the cap screws; then

install the cap screws and tab washer to the

camshaft sprocket. Tighten cap screws to 1.5 kg-m

(11 ft-lb).

2 !

"!

$

-)6

!

$& !

"""$,

&

!

!!$

16. When the camshaft assembly is seated, ensure the

following.

A. Piston still at top-dead-center.

B. Camshaft lobes directed down (toward the

piston).

C. Camshaft alignment marks parallel to the valve

cover mating surface.

D. Recessed side of the sprocket directed toward

the cam lobes.

E. Camshaft alignment pin and sprocket

alignment hole (smallest) are aligned.

17. Install the cylinder head plug with the open end

facing the camshaft.

18. Remove the cap screw from the end of the chain

tensioner. Account for the plunger, spring, and

O-ring.

-)4?

19. Depress the spring-loaded lock and push the

plunger into the tensioner.

-)46

! CAUTION

,& "

!&!$

! CAUTION

&"

!$ , !

"$

RepairPro Service Manual