ATV Arctic Cat 2002. Service Manual - part 6

3

459)

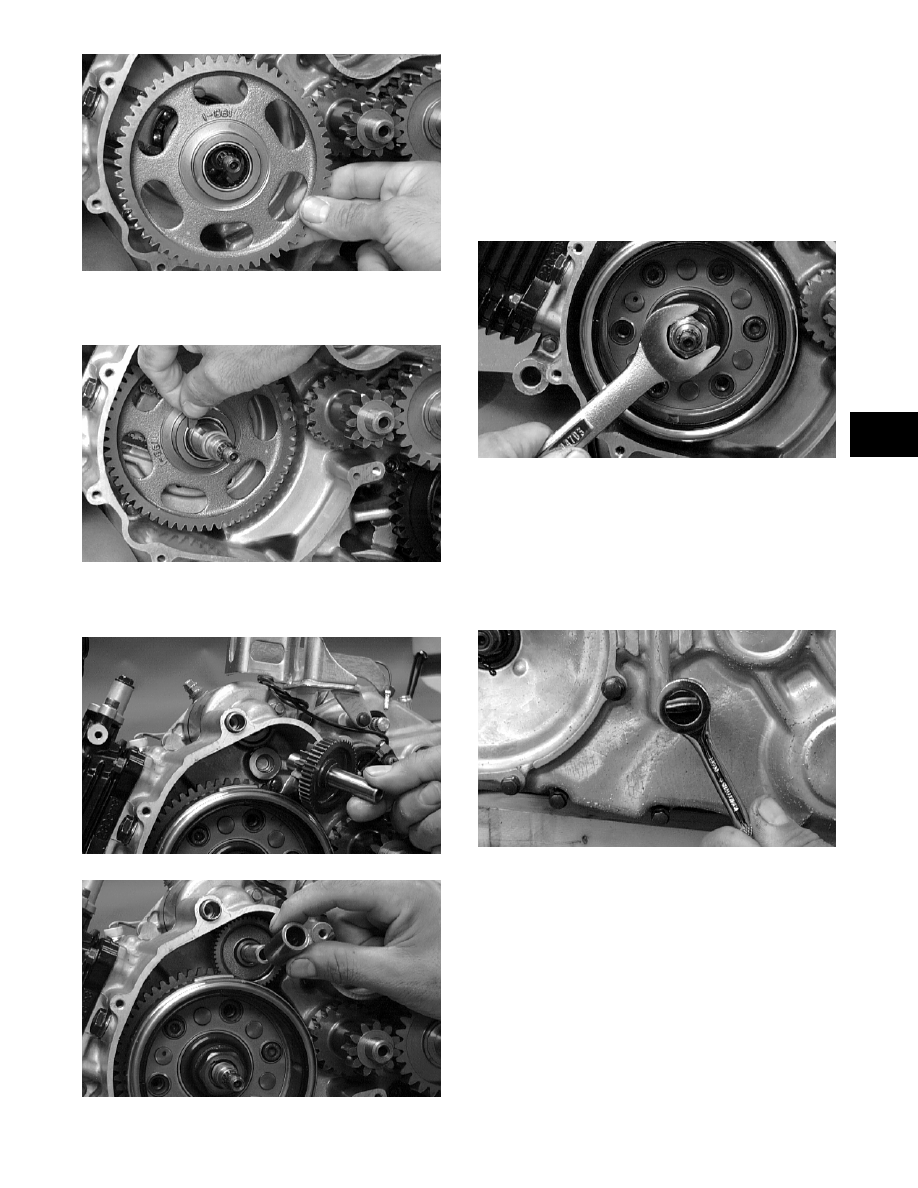

15. Place the magneto rotor into position on the

crankshaft making sure the key is in place.

45?)

16. Install the starter idler gear and shaft; then install

the spacer.

455)

454)

C. Stator Assembly/Cover

D. Starter Cup

E. Recoil Starter

%! 6 !

!!$

17. Install the magneto rotor nut on the crankshaft and

tighten until the rotor is properly seated; then

tighten to 16 kg-m (116 ft-lb).

46)

18. Place the gasket and left-side cover into position

on the crankcase making sure the alignment pins

are in place.

19. Install the cap screws to secure the left-side cover

noting the location of the different-sized cap

screws; then tighten to 0.9-1.3 kg-m (6.5-9.5

ft-lb).

44)

20. Place the starter cup into position on the

crankshaft making sure a new, lubricated O-ring is

inside the cup. Tighten the nut with lock washer to

3.5 kg-m (25 ft-lb).

RepairPro Service Manual