CFMoto ATV CF500/CF500-A. Service Manual - part 15

16. Carburetor

z

If float height is not within the specification, check

the valve seat and needle valve;

z

If either of valve seat or needle valve is worn,

replace both;

z

If both are fine, adjust float height by bending the

float tang

①

on the float;

z

Measure float height again till it’s within the

specification

Fuel Level

z

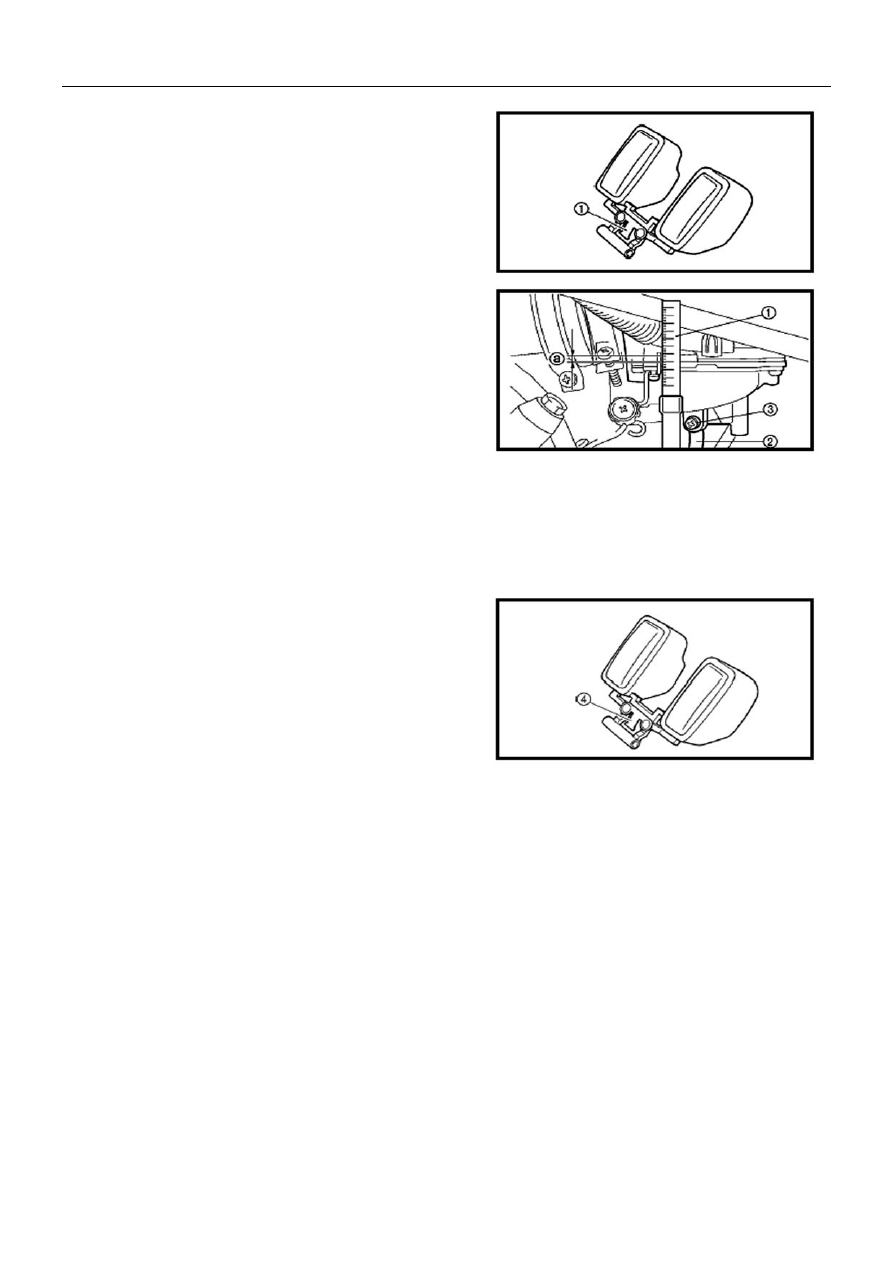

Place carburetor on a level surface. Connect fuel

level gauge

①

with drain pipe

②

;

Tool: Fuel Level Gauge

z

Loosen drain screw

③

z

Keep fuel level gauge vertical next to the float

chamber line and read the fuel level “a”

Fuel Level: 3.5

±

0.5mm

z

If the fuel level is not within the specification, adjust

the fuel level;

z

Remove

carburetor

z

Check valve seat and needle valve

z

If either of valve seat or needle valve is worn,

replace both;

z

If both are fine, adjust float height by bending the

float tang

①

on the float;

z

Install

carburetor

z

Check again the fuel level

Carburetor Assembly

Reverse the disassembly procedure for assembly

16-5