CFMoto motorcycle CF650NK. Service Manual - part 10

PERIODIC MAINTENANCE 2-7

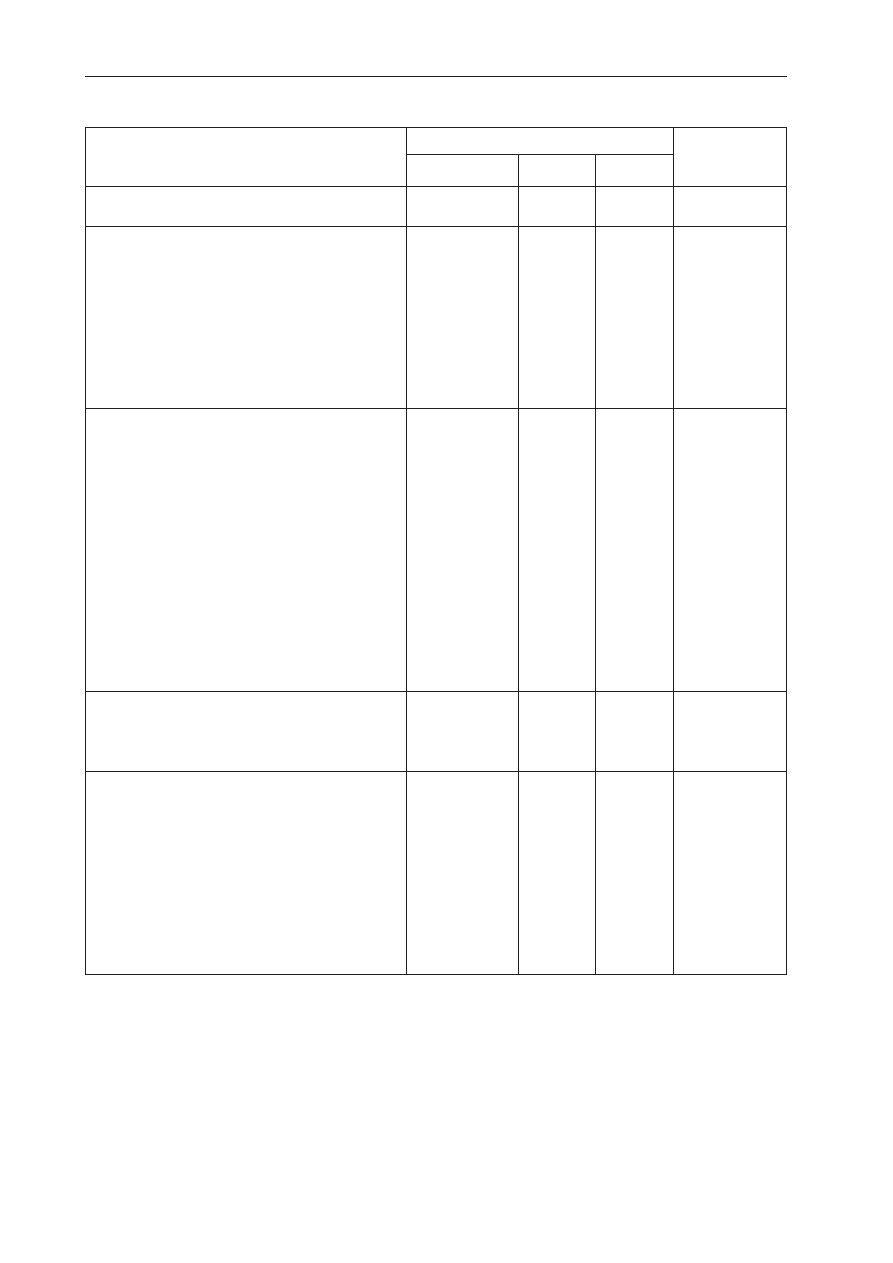

Fastener

Torque

Remarks

N·m

kgf·m

ft·lb

Muf

fl

er Body Mounting Bolt (Rear)

20

2.0

15

Baf

fl

e Plate Bolts

6

0.60

52in·lb

See text

Clutch

Oil Filler Plug

–

–

–

Finger tighten

Clutch Cover Mounting Bolts

10

1.0

87in·lb

Clutch Spring Bolts

10

1.0

87in·lb

Clutch Hub Nut

132

13.5

98

R

Clutch Lever Clamp Bolts

10

1.0

87in·lb

S

Oil Pump Chain Guide Bolts

12

1.2

106in·lb

L

Clutch Cable Holder Bolts

10

1.0

87in·lb

L

Clutch Cable Clamp Bolt

10

1.0

87in·lb

Engine Lubrication

Drain Bolt

30

3.0

22

Filler Plate Bolts

10

1.0

87in·lb

L

Oil Filter

17

1.75

13

EO,R

Holder Mounting Bolt

25

2.5

18

L

Oil Pan Bolts

12

1.2

106in·lb

Oil Pump Chain Guide Bolts

12

1.2

106in·lb

L

Oil Pipe Plate Bolt

10

1.0

87in·lb

L

Oil Pressure Relief Valve

15

1.5

11

L

Oil Pressure Switch

15

1.5

11

SS

Oil Pump Cover Bolts

10

1.0

87in·lb

L

Lower Fairing Bracket Bolts

12

1.2

106in·lb

L

Oil Pump Sprocket Bolt

12

1.2

106in·lb

L,Lh

Oil Passage Plug

20

2.0

15

L

Engine Removal/Installation

Rear Engine Mounting Nuts

45

4.6

32

S

Engine Mounting Bracket Bolts

25

2.5

18

S

Front Engine Mounting Bolts

45

4.6

32

S

Crankshaft/Transmission

Breather Plate Bolts

10

1.0

87in·lb

L

Crankcase Bolts (M9, L = 113 mm)

44

4.5

32

MO,S

Crankcase Bolts (M9, L = 83 mm)

44

4.5

32

MO,S

Crankcase Bolts (M8, L = 73 mm)

35

3.6

26

MO,S

Crankcase Bolts (M8, L = 60 mm)

35

3.6

26

MO,S

Crankcase Bolts (M8, L = 110 mm)

27.5

2.8

20

S

Crankcase Bolts (M8, L = 50 mm)

27.5

2.8

20

S

Crankcase Bolts (M7)

20

2.0

15

S

Upper Crankcase Bolts

27.5

2.8

20

S