Hyundai Excavator R210LC-7. Service and repair manual - page 21

6 - 30

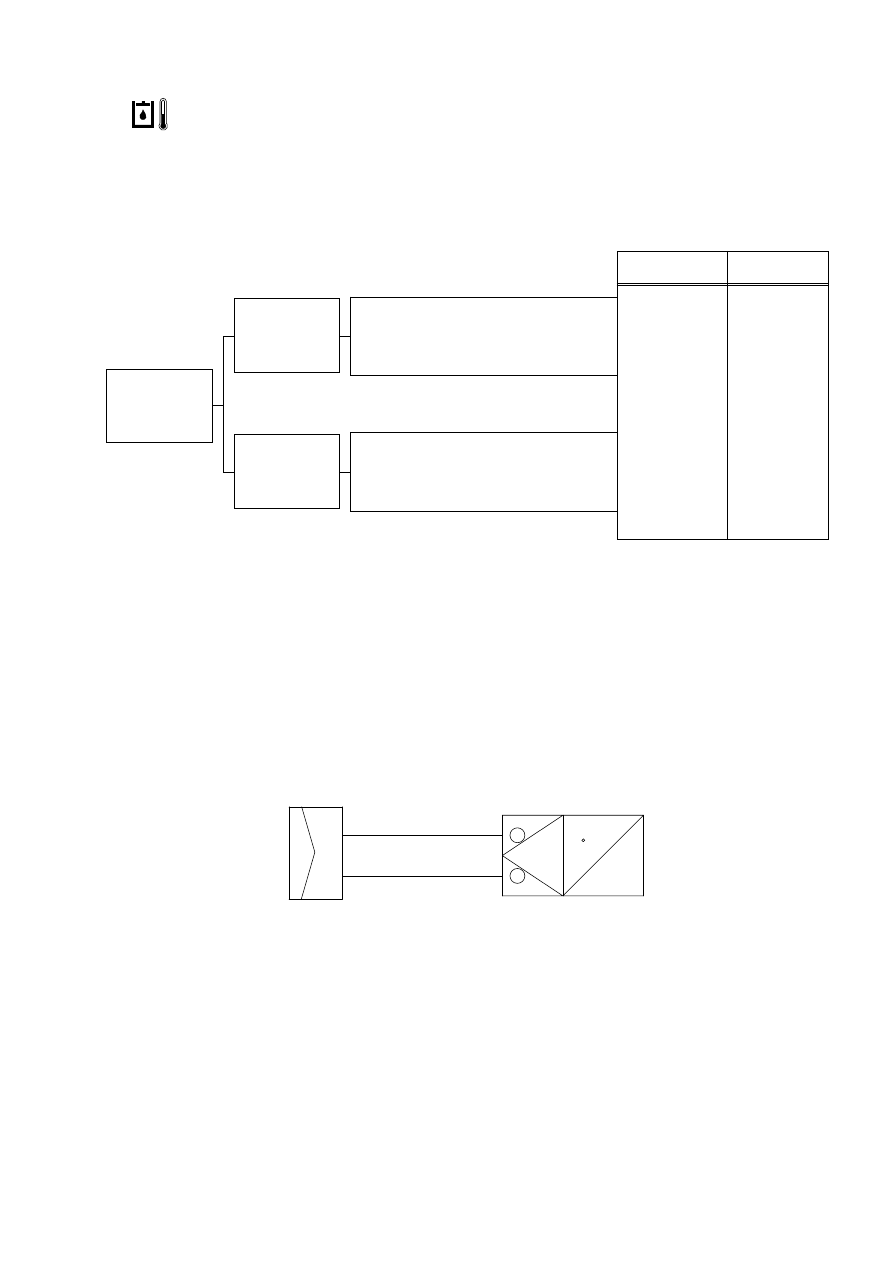

7. WHEN HYDRAULIC OIL TEMPERATURE WARNING LAMP LIGHTS UP

(Engine is started)

Before disconnecting the connector, always turn the starting switch OFF.

Before carrying out below procedure, check all the related connectors are properly inserted.

After checking, insert the disconnected connectors again immediately unless otherwise specified.

Cause

Remedy

High temperature

Defective torque

sensor

Short circuit

Defective controller

Check hydraulic

oil temperature

(100 C

2 C ) ,

Replace

Replace

Check and repair

Replace

HYDRAULIC OIL

TEMPERATURE SENDER

CD-1

C

2

1

CN-51

34

CONTROLLER

31

Starting switch : ON

Engine : Start

Does display go

off when

disconnect CD-1?

Resistance

between CN-51

(31,34) is 0~1 ?

Starting switch : OFF

Disconnect CN-51

Resistance

between CD-1

(1,2) is in range

of 130~150 ?

Starting switch : ON

Disconnect CD-1

YES

YES

YES

NO

NO

NO

29076ES04