Hyundai Excavator R450LC-7. Service and repair manual - page 15

4-39

No. of

pin

Receptacle connector(Female)

Plug connector(Male)

12

1

7

6

12

174045-2

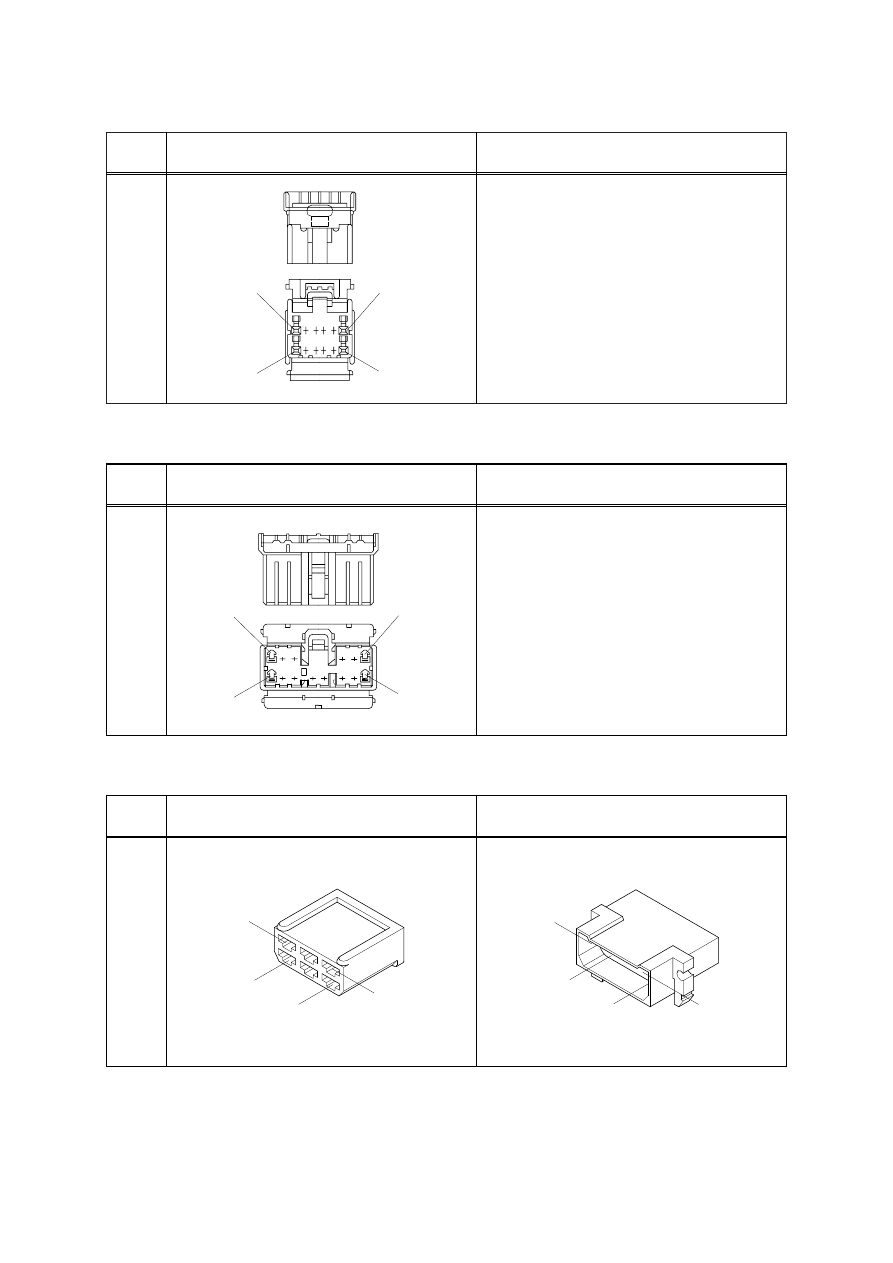

AMP 040 MULTILOCK CONNECTOR

8)

No. of

pin

Receptacle connector(Female)

Plug connector(Male)

14

1

7

6

14

173852

AMP 070 MULTILOCK CONNECTOR

9)

No. of

pin

Receptacle connector(Female)

Plug connector(Male)

6

3

6

1

4

925276-0

1

4

3

6

480003-9

AMP FASTIN - FASTON CONNECTOR

10)