BMW AG Motorcycle (K1100LT, K1100RS). Manual - part 2

00.11

Key to maintenance intervals

–

Inspection at 1000 km (600 miles)I

–

BMW Service at 10,000 km (6000 miles))II

–

BMW Inspection at 20,000 km (12,000 miles)III

–

BMW Annual Service

IV

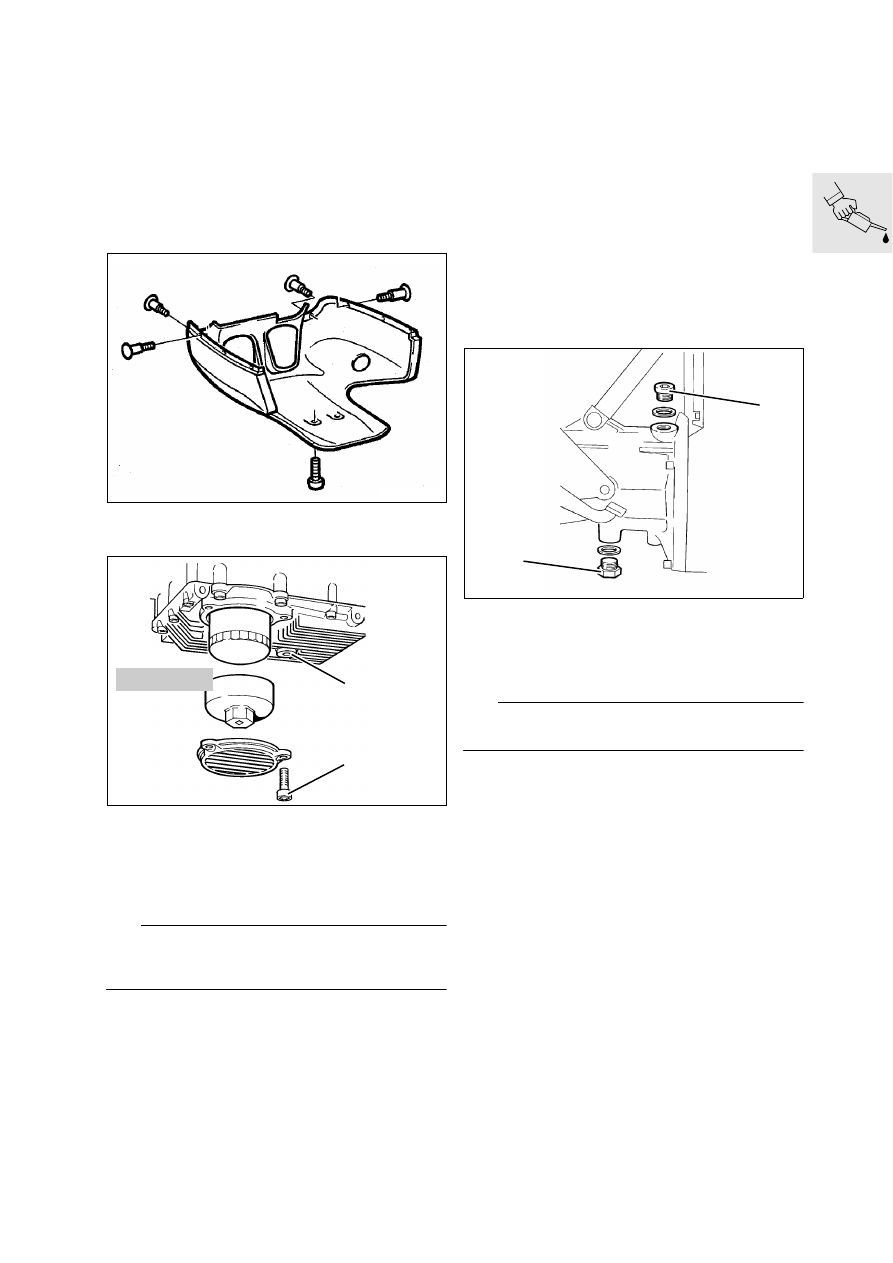

Changing engine oil

Inspections I, II, III, IV

•

[RS] Remove lower section of fairing.

•

Change oil at operating temperature.

•

Oil drain plug (1).

•

Remove oil filter cover retainer (2).

•

Unscrew oil filter with special wrench

BMW No. 11 4 650.

L

Note:

Coat sealing ring on new oil filter element with oil.

Screw in oil filter handtight, take note of hint at filter.

•

Replace O-ring in cover, if necessary.

X

Tightening torques:

Oil drain plug................................................ 18 Nm

Cover to oil sump ........................................... 6 Nm

Quantities:

Oil content ................................ 3.50 l (6.16 Imp.pt)

Oil content with filter change ....... 3.75 l (6.6 Imp.pt)

See service data for oil grades ................ Seite 00.3

Changing oil in transmission

(gearbox)

Inspections I, III, IV

•

Drain off oil with engine at operating tempera-

ture.

•

Oil drain plug (1)

•

Oil filler plug (2)

L

Note:

Renew sealing rings.

X

Tightening torques:

Oil drain plug................................................ 20 Nm

Oil filler plug ................................................. 20 Nm

Quantities:

Oil filling capacity .................... 0.85 l (1.496 Imp.pt)

See service data for oil grades ................Page 00.3

LT000010

LT000020

1

2

11 4 650

LT000030

2

1