Volkswagen Jetta / Bora: Electrical System Manual - part 44

Removing and installing spray jet as‐

sembly

Removing:

– Switch off ignition and all electrical consumers and pull out

ignition key.

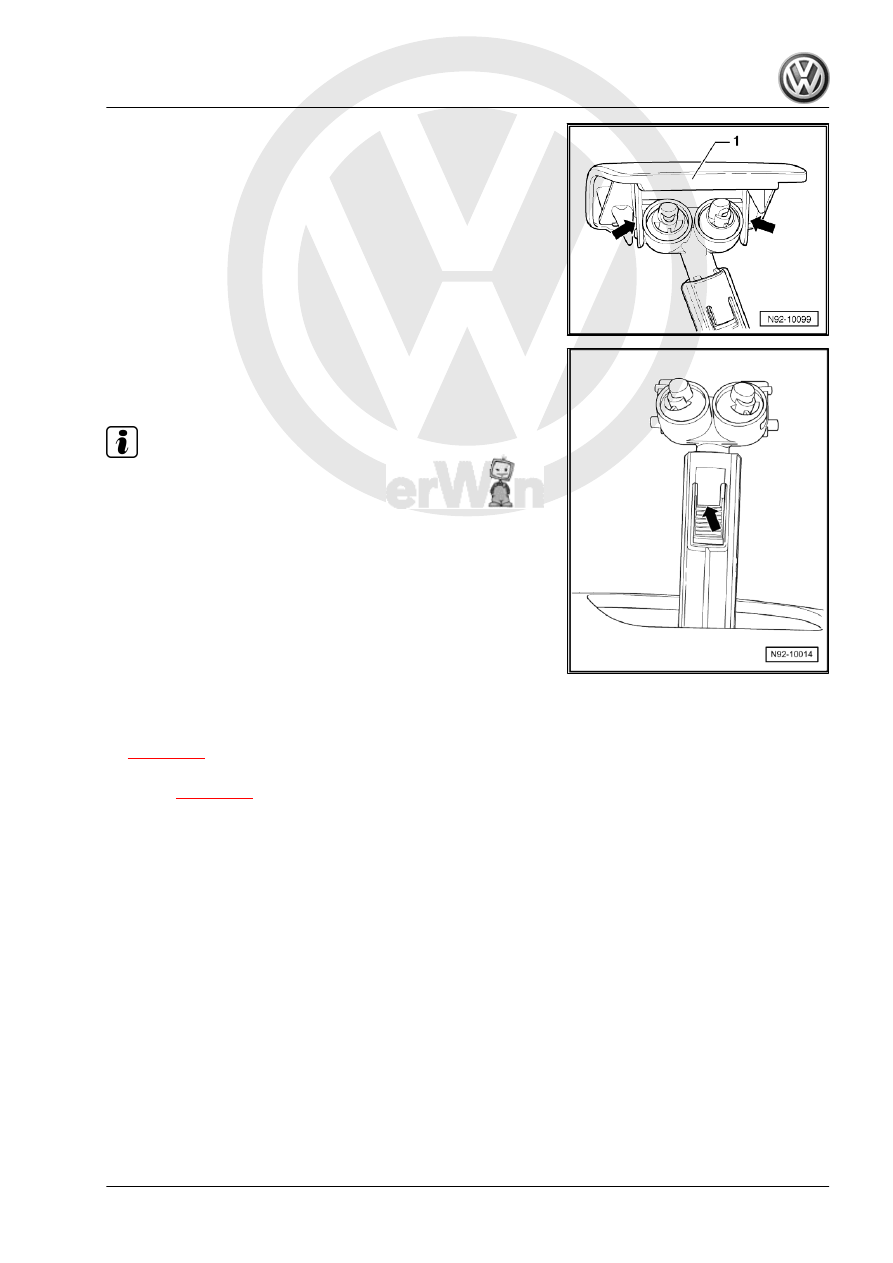

– Pull spray jet with cover cap -1- onto stop out of bumper cover.

– Unclip cap -1- from mounting points -arrows- on washer spray

jet assembly.

– Lever locking hooks -arrow- up slightly and pull out spray jet

assembly.

Installing:

Note

The degree to which the cover cap of the spray jet is pulled down

onto the bumper cover can be adjusted using the clips on the

washer spray jet assembly. If the washer spray jet assembly is

not pulled in far enough, the cover cap will not seat correctly. If

the washer spray jet assembly is pulled in too far, the cover cap

and the bumper cover could be pushed out of shape.

– Push washer spray jet assembly in pop-up cylinder until it en‐

gages.

– Fit cover cap on washer spray jet assembly and allow pop-up

cylinder to retract.

– Check the cover cap is seated correctly on the bumper cover.

– If necessary, adjust seat of cover cap by pushing washer spray

jet assembly in higher or lower position on pop-up cylinder.

– Bleed the headlight washer system after completing work

– Check headlight washer system spray jets and adjust if nec‐

essary

.

3.5

Adjusting headlight washer system jets

⇒ Maintenance ; Booklet 18.1

3.6

Bleeding the headlight washer system

To guarantee sound functioning, the headlight washer system

must be bled following assembly work or when operated for the

first time.

– Fill reservoir for windscreen and headlight washer systems.

– Start the engine.

– Switch “ON” the headlight.

– Operate headlight washer system several times (3-5 times, 3

seconds each time).

– Repeat this bleeding procedure until the pop-up cylinders and

spray jets are functioning soundly.

Jetta 2005 ➤ , Bora 2006 ➤

3. Headlight washer system

173