Suzuki Grand Vitara JB419. Manual - part 57

Engine Lubrication System: 1E-8

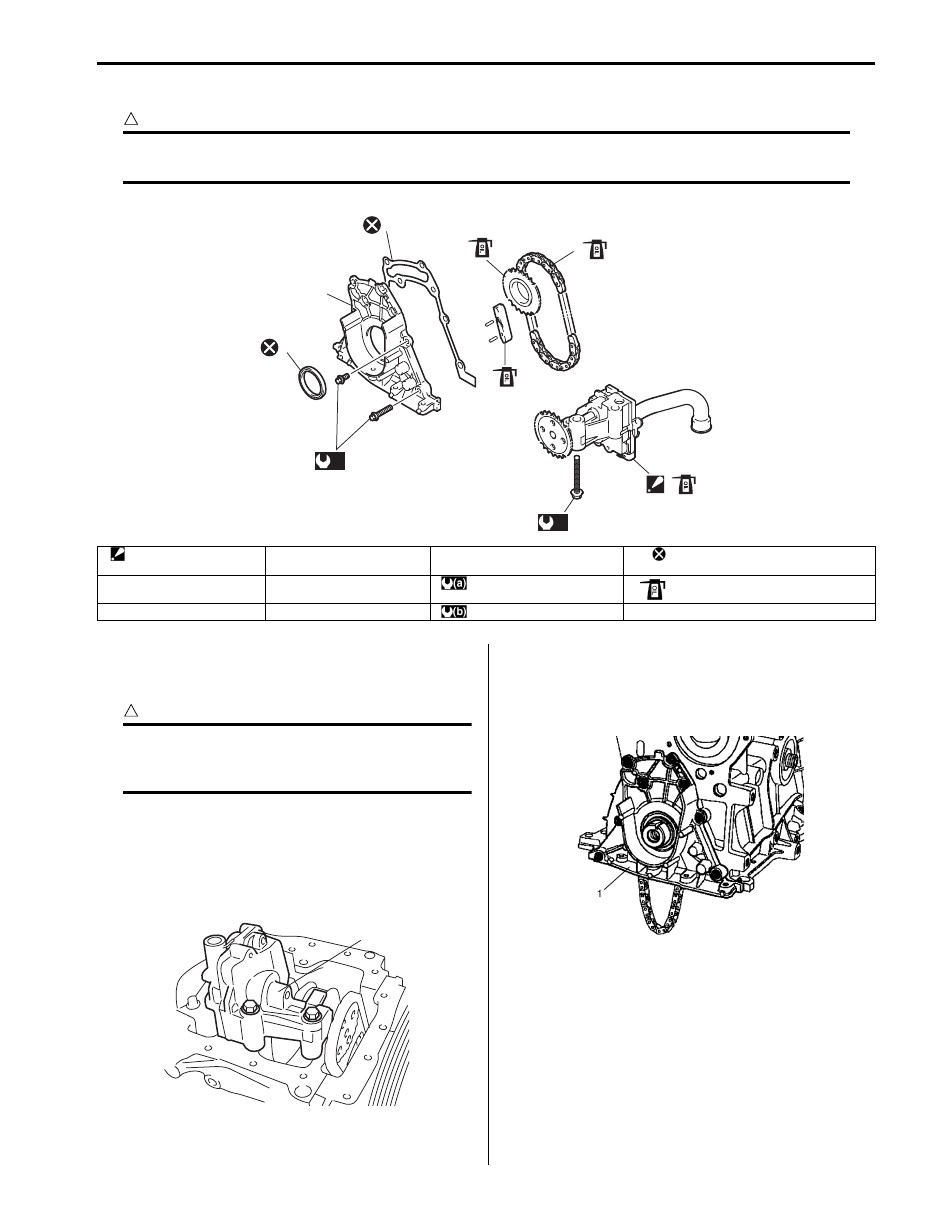

Oil Pump, Oil Pump Chain and Gasket Holder Plate Component

S5JB0B1506003

CAUTION

!

Never disassemble oil pump. Disassembly will spoil its original function. If faulty condition is found,

replace it with new one.

Oil Pump, Oil Pump Chain and Gasket Holder

Plate Removal and Installation

S5JB0B1506004

CAUTION

!

Never disassemble oil pump. Disassembly

will spoil its original function. If faulty

condition is found, replace it with new one.

Removal

1) Remove oil pan and oil pump strainer referring to “Oil

Pan and Oil Pump Strainer Removal and

Installation”.

2) Remove oil pump (1) from cylinder block.

3) Remove timing belt and crankshaft timing pulley

referring to “Timing Belt and Belt Tensioner Removal

and Installation in Section 1D”.

4) Remove gasket holder plate (1) from cylinder block.

4

(a)

(b)

6

1

5

7

2

3

I5JB0B150043-01

1. Oil pump

: Do not disassemble.

4. Gasket holder plate

7. Oil pump chain tensioner

: Do not reuse.

2. Oil pump drive sprocket

5. Gasket holder plate gasket

: 24 N

⋅m (2.4 kgf-m, 17.5 lb-ft)

: Apply engine oil to sliding surface of

each part.

3. Oil pump chain

6. Crankshaft oil seal

: 14 N

⋅m (1.4 kgf-m, 10.5 lb-ft)

1

I5JB0B150030-01

I5JB0B150031-01