Suzuki Grand Vitara JB416 / JB420. Manual - part 188

3C-66 Transfer: Motor-Shift Type (Transfer with Shift Actuator)

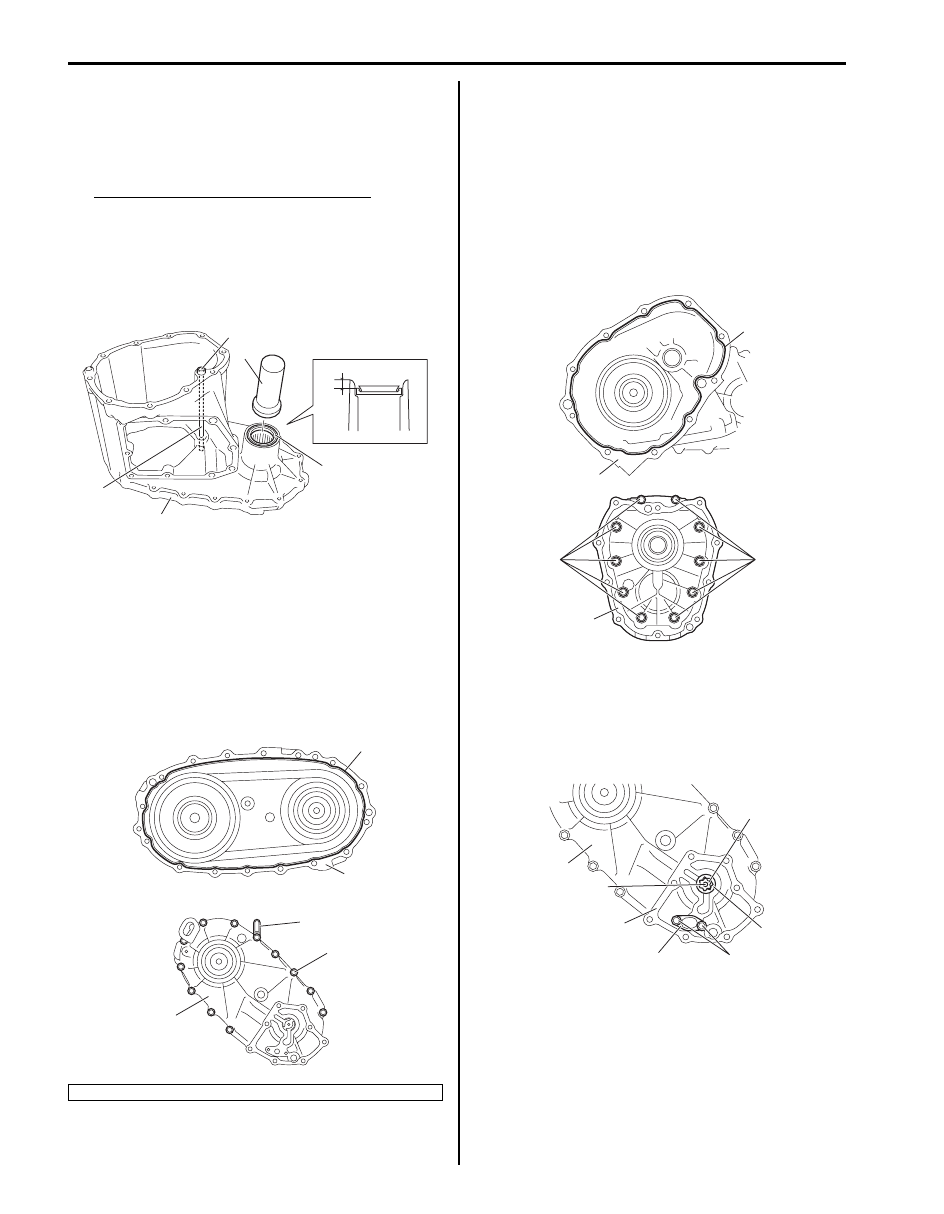

15) Install oil pipe (1) and knock pin (2) into center case

(3).

16) Install new front oil seal No.1 (4) into center case

using special tool as shown in figure, and then apply

grease to oil seal lip.

Distance between case and oil seal “a”

: 3.5 – 4.5 mm (0.138 – 0.177 in.)

“A”: Grease 99000–25010 (SUZUKI Super

Grease A)

Special tool

(A): 09913–70123

17) Clean mating surface of both center case and rear

case (1), apply sealant to rear case as shown in

figure by such amount that its section is 1.2 mm

(0.047 in.) in diameter, mate center case with rear

case and then tighten bolts (2) to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Rear case bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-ft)

18) Clean mating surface of both center case (1) and

front case, apply sealant to center case as shown in

figure by such amount that its section is 1.2 mm

(0.047 in.) in diameter, mate front case (3) with

center case and then tighten bolts (2) to specified

torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Rear case bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-ft)

19) Install oil strainer (1) to rear case (2).

Tightening torque

Strainer bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

20) Install oil pump inner rotor (3), outer rotor (4) and

drive pin (5) to rear case (6).

3. Clamp

2

1

3

(A)

4, “A”

“a”

I5JB0A331046-03

“A”

1

3

1

2, (a)

I5JB0A331047-02

“A”

1

2, (a)

2, (a)

3

I5JB0A331048-03

2

5

6

1

(a)

4

3

I5JB0A331050-01