Suzuki Grand Vitara JB416 / JB420. Manual - part 165

3B-13 Differential: Front

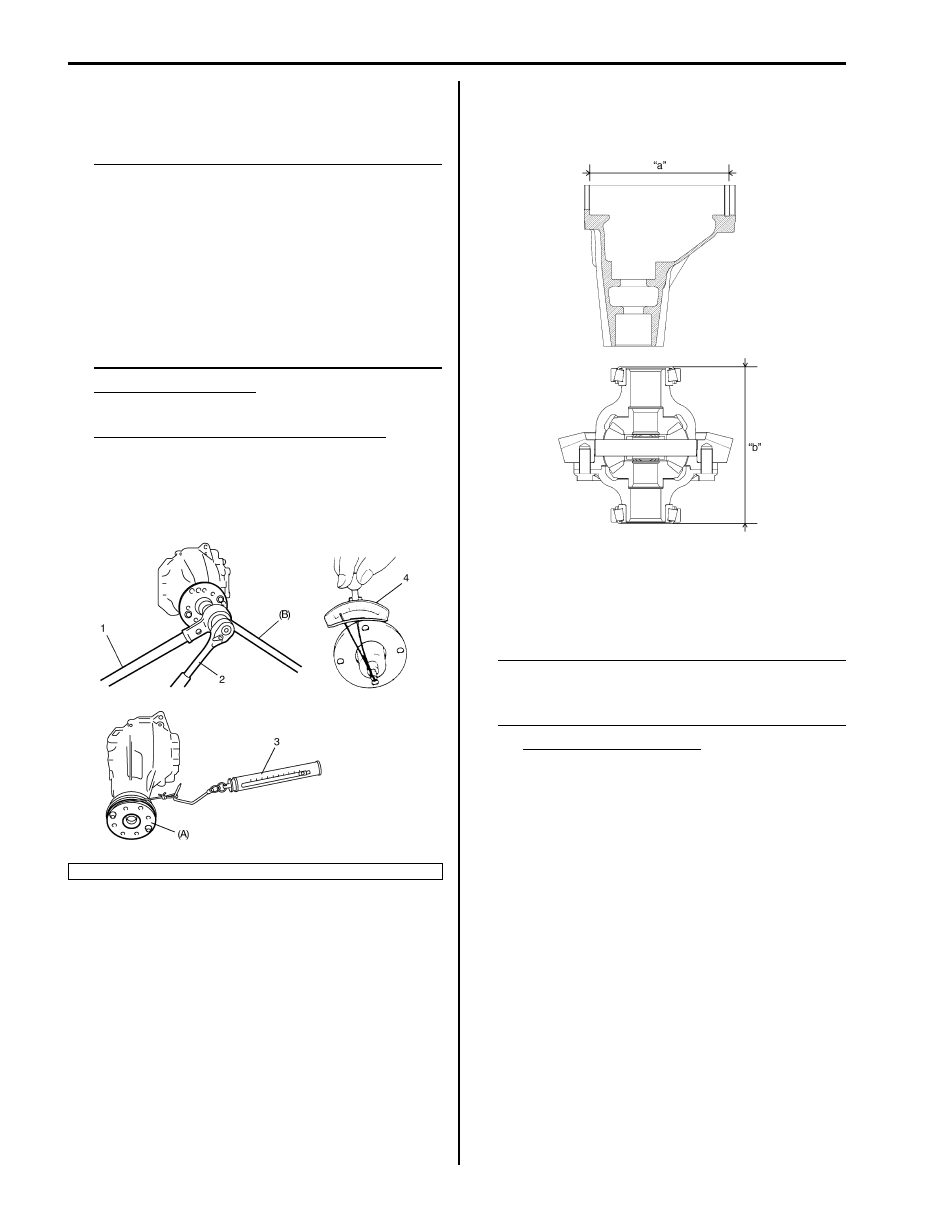

17) While tightening flange nut gradually with special

tool and power wrench (4 – 10 magnification) (1), set

preload of pinion to specification.

NOTE

• Before taking measurement with spring

balance (3) or torque wrench (4), check for

smooth rotation by hand.

• On measuring preload, rotate the drive

bevel pinion about 1 rotation per 2

seconds.

• Be sure to tighten gradually and carefully

till specified starting torque is obtained.

Turning back overtightened flange nuts

should be avoided.

Pinion bearing preload

0.9 – 1.7 N

⋅m (9.0 – 17.0 kg-cm, 7.8 – 14.7 lb-in.)

Spring measure reading with special tool

20 – 40 N (2.0 – 4.0 kg, 4.4 – 8.8 lb)

Special tool

(A): 09922–75222

(B): 09922–66021

18) Select differential side bearing shim as follows.

a) Measure dimension “a” and “b” using vernier

caliper.

b) Calculate dimension “a” – “b”, and select shims

from among following available size so that total

of thickness of right side and left side shims may

reach the calculated value.

NOTE

Select shims so that thickness of right side

shims and left side shims become almost

even.

Available shim thickness

Right side: 1.75, 1.85, 1.95, 2.00, 2.05, 2.15

and 2.25 mm (0.069, 0.073, 0.077, 0.079, 0.081,

0.085 and 0.089 in.)

Left side: 2.75, 2.85, 2.95, 3.00, 3.05, 3.15 and

3.25 mm (0.108, 0.112, 0.116, 0.118, 0.120,

0.124 and 0.128 in.)

2. Socket wrench

I5JB0A321036-02

I5JB0A321037-04