Suzuki Grand Vitara JB416 / JB420. Manual - part 156

2C-30 Rear Suspension:

6) Remove floor jack from lower arm.

7) Install rear brake hose bracket (1) and then tighten

rear brake hose bracket bolt (2) to specified torque.

Tightening torque

Rear brake hose bracket bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

8) Install ABS wheel sensor (1) (if equipped) and then

tighten wheel sensor bolt (2) to specified torque.

Tightening torque

Wheel sensor bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-

ft)

9) Install rear wheel hub assembly referring to “Rear

Wheel Hub Assembly Removal and Installation”.

10) Fill reservoir with brake fluid and bleed brake

system. Refer to “Air Bleeding of Brake System in

Section 4A”.

11) Upon completion of all jobs, depress brake pedal

with about 30 kg (66 lbs) load three to five times so

as to obtain proper drum-to-shoe clearance. Adjust

parking brake cable. Refer to “Parking Brake Check

and Adjustment in Section 4D”.

12) Install rear wheels.

13) Check to ensure that brake drum is free from

dragging and proper braking is obtained.

14) Lower hoist and tighten rear wheel bolts to specified

torque.

Tightening torque

Wheel nut: 100 N·m (10.0 kgf-m, 72.5 lb-ft)

15) Bounce vehicle up and down to stabilize suspension.

16) Tighten each bolts to specified torque with vehicle

weight on suspension.

NOTE

It is the most desirable to have vehicle off

hoist and in non-loaded condition when

tightening them.

Tightening torque

Lower arm outer bolt: 135 N·m (13.5 kgf-m, 98.0

lb-ft)

Trailing rod rear bolt: 135 N·m (13.5 kgf-m, 98.0

lb-ft)

Control rod outer bolt: 135 N·m (13.5 kgf-m, 98.0

lb-ft)

17) Perform brake test (foot brake and parking brake).

18) Check each installed part for fluid leakage.

19) Check rear toe and camber adjust it as necessary.

For check and adjustment procedures, refer to “Rear

Wheel Alignment Inspection and Adjustment”.

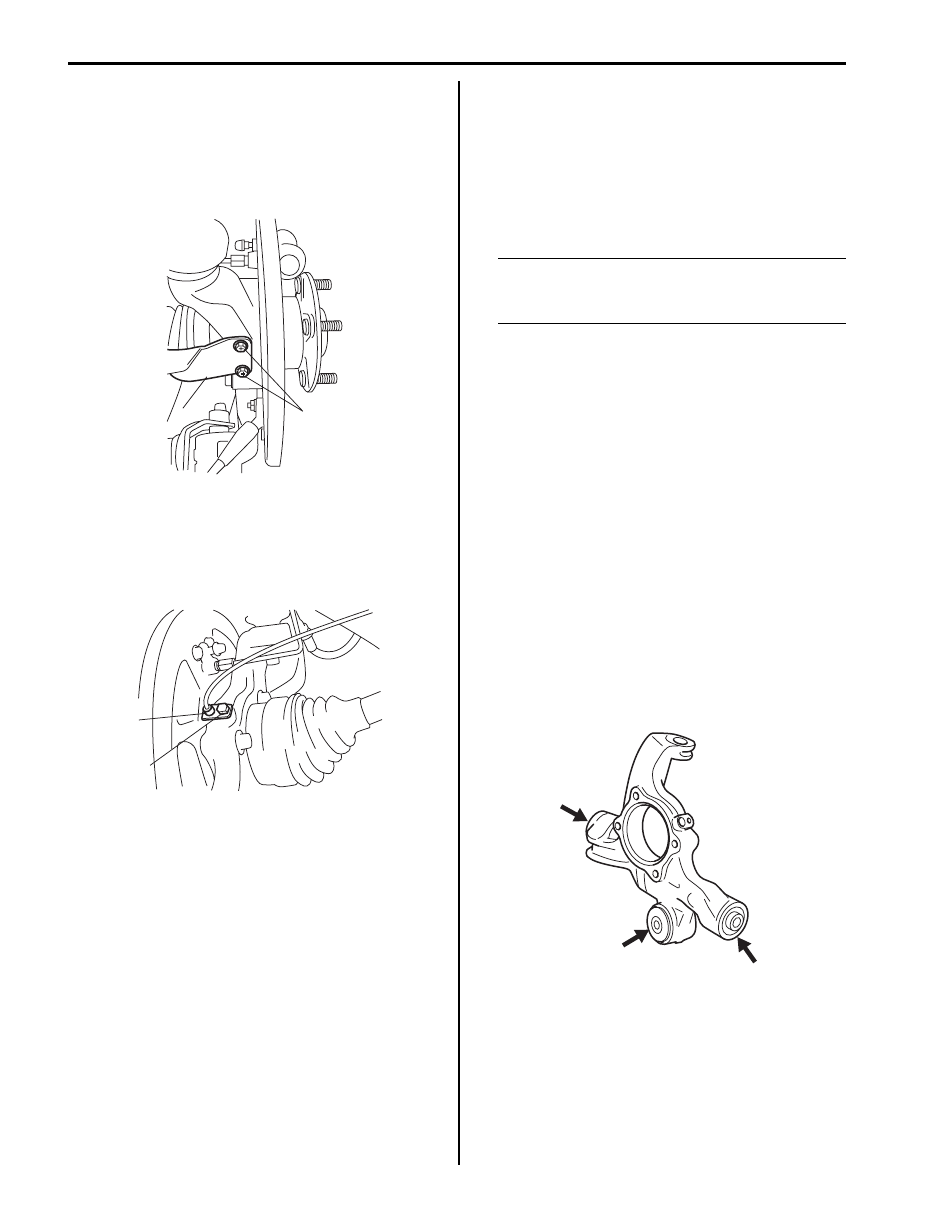

Rear Suspension Knuckle Check

S5JB0A2306024

• Inspect for cracks, deformation or damage.

• Inspect bushing for damage, wear or breakage. If any

faulty condition is found, replace rear suspension

knuckle assembly.

Rear Suspension Fasteners Check

S5JB0A2306025

Check each bolt and nut fastening suspension parts for

tightness. Tighten loose one, if any, to specified torque

referring to the figure in “Rear Suspension Construction”.

2,(a)

1

I5JB0A230074-01

1

2,(a)

I5JB0A230075-01

I5JB0A230078-01