Suzuki Grand Vitara JB416 / JB420. Manual - part 131

1H-3 Ignition System:

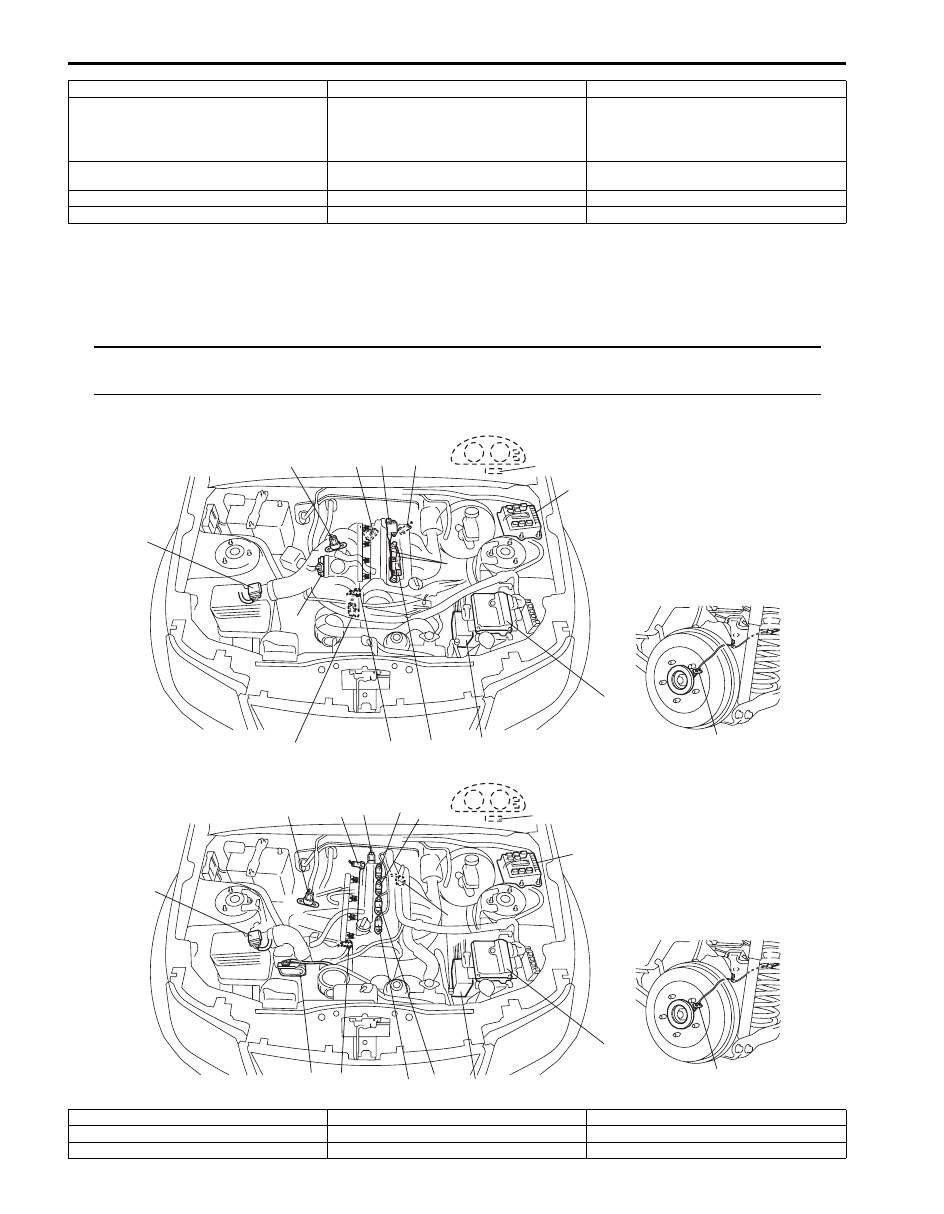

Component Location

Ignition System Components Location

S5JB0A1803001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

2. Main relay

10. No.4 spark plug

18. Ignition coil assembly for No.1

3. Ignition coil assembly for No.1 and No.4 spark

plugs

11. Sensed information (MAP sensor, ECT

sensor, MAF and IAT sensor, TP sensor,

Knock sensor, wheel speed signal (ABS),

Electric load signal, Engine start signal,

Torque reduction signal (TCM))

19. Ignition coil assembly for No.2

4. Ignition coil assembly for No.2 and No.3 spark

plugs

12. ECM

20. Ignition coil assembly for No.3

5. CMP sensor

13. Fuse box No.2

21. Ignition coil assembly for No.4

6. CKP sensor

14. “IGN” fuse

1

1

2

3

4

5

6

7

8

9

10

11

12*

14*

13

13

15

16

17

18

4

5

6

7

8

9

11

12*

14*

[A]

[B]

19

19

I5JB0A180002-03

[A]: For M16 engine

7. ECT sensor

15. Ignition coil assembly for No.1 (for J20 engine)

[B]: For J20 engine

8. MAF and IAT sensor

16. Ignition coil assembly for No.2 (for J20 engine)

1. ECM

9. Electric throttle body assembly

17. Ignition coil assembly for No.3 (for J20 engine)