Suzuki Grand Vitara JB416 / JB420. Manual - part 125

1G-2 Fuel System:

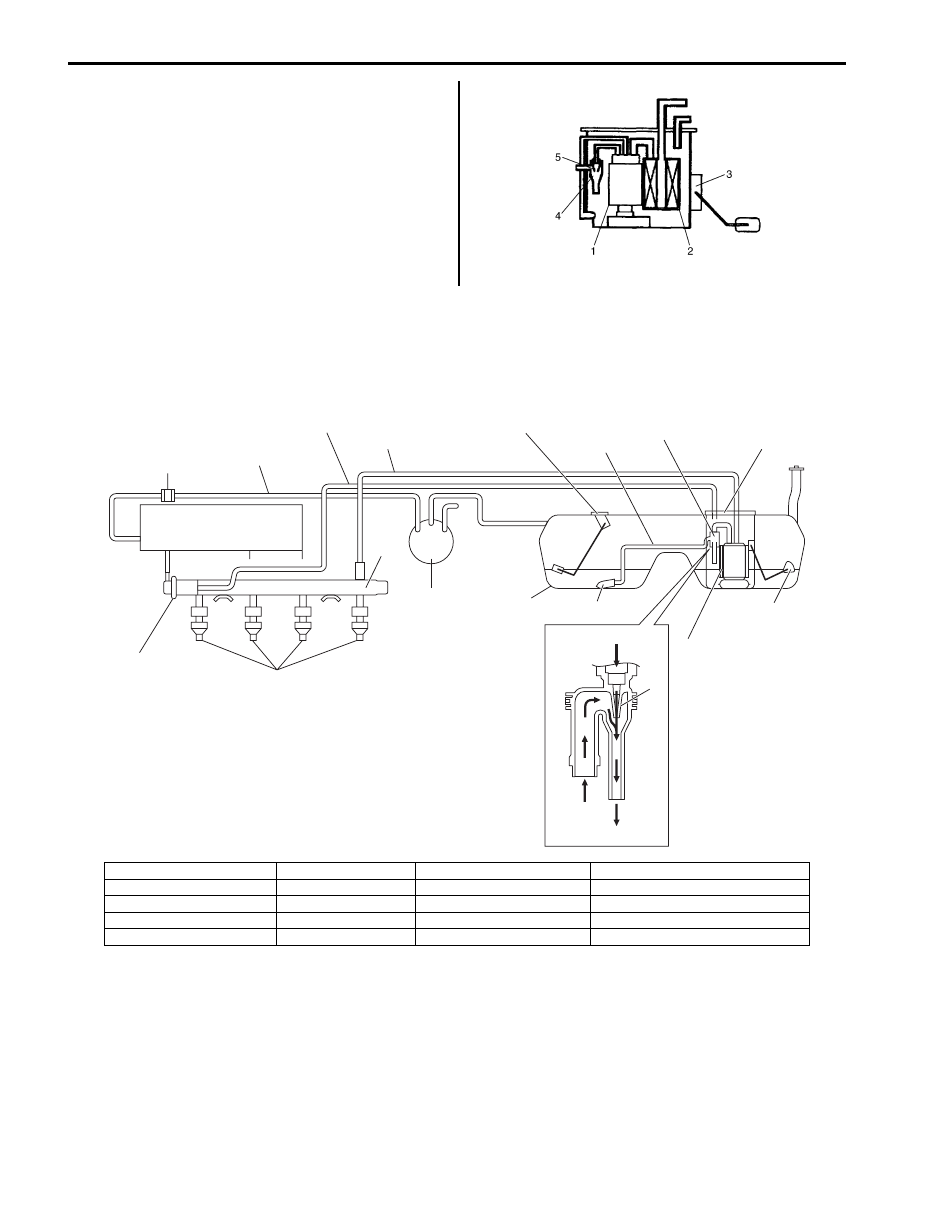

Fuel Pump Description

S5JB0A1701003

The fuel pump (1) is an in-tank type electric pump.

Incorporated in the pump assembly are;

a fuel filter (2) included and a fuel level gauge (3)

attached.

Also, the jet pump (4) installed in the fuel pump sucks up

the fuel from the sub fuel level sensor side to main fuel

level sensor side through the fuel suction pipe / hose by

using the negative pressure produced when the part of

pressurised fuel with the fuel pump passes the venturi

(5).

Schematic and Routing Diagram

Fuel Delivery System Diagram

S5JB0A1702001

I5JB0A171001-03

20

7

10

6

9

13

15

14

2

12

11

19

17

18

16

1

4

5

3

8

I5JB0A171002-03

1. Fuel tank

6. Fuel feed line

11. Fuel filter

16. Fuel suction filter

2. Fuel pump

7. Fuel vapor line

12. Main fuel level sensor

17. Pressurised fuel from fuel pump

3. Fuel pressure regulator

8. Intake manifold

13. Sub fuel level sensor

18. Fuel feeded from fuel suction hose

4. Delivery pipe

9. EVAP canister

14. Jet pump

19. Venturi

5. Fuel injector

10. Fuel return line

15. Fuel suction pipe / hose

20. EVAP canister purge valve